Fireproof mixing device for mining

A technology for mixing devices and mines, applied in mixers, mixers with rotary mixing devices, transportation and packaging, etc., can solve the problems of uneven mixing, affecting the progress and effect of fire prevention and control, and poor mixing effect, etc. To achieve the effect of simple structure, optimal foaming and injection, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

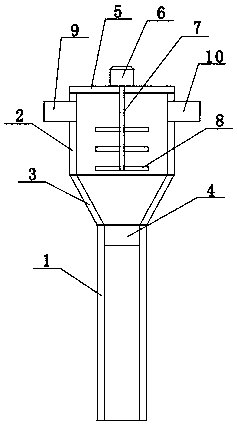

[0010] see figure 1 , the mining fireproof mixing device of the present invention includes a grouting pipe 1, and also includes a mixing pipe 2, the diameter of the mixing pipe 2 is greater than the diameter of the grouting pipe 1, and the mixing pipe 2 communicates with the grouting pipe 1 through a transition pipe 3 A one-way valve 4 is arranged at the joint between the grouting pipe 1 and the transition pipe 3, the mixing pipe 2 is provided with an end cover 5, the end cover 5 is provided with a micro motor 6, and the micro motor 6 is provided with a stirring shaft 7, The stirring shaft 7 is arranged in the mixing tube 2, and the stirring shaft 7 is provided with a stirring blade 8, and the side of the mixing tube 2 is provided with a feed pipe 9 and an auxiliary material pipe 10, and the stirring blades 8 are several pairs, and are evenly arranged on the stirring shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com