Small-sized track plate grooving equipment

A technology for grooving equipment and track shoes, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as eye trauma, reduced work efficiency, and difficulty in normal work, so as to ensure the quality of grooving and improve grooving. Efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

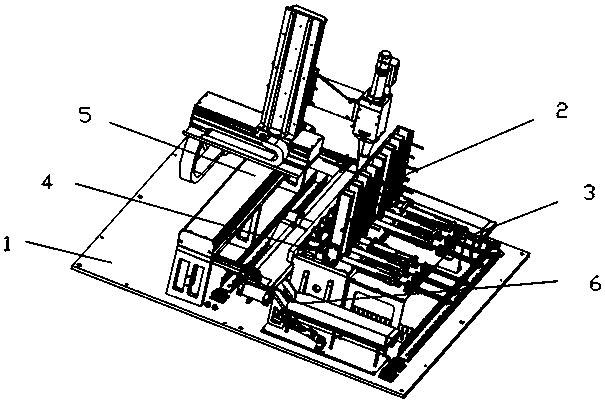

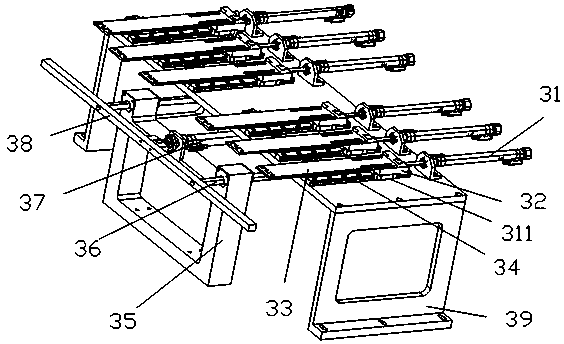

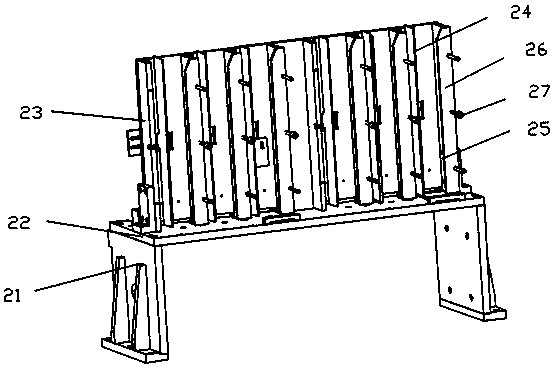

[0037] Examples, please refer to Figure 1-9 , a small track shoe slotting equipment, including a fixing frame 1, a fixing device 2, a pushing device 3, a working platform 4, a slotting device 5 and a collecting device 6, the fixing device 2 includes a fixing seat 21, and the fixing device 2 is placed to be For grooved track shoes, the pushing device 3 includes a first push pedal cylinder 31 and a second push pedal cylinder 37, the working platform 4 includes a workbench drive cylinder 43 and a pressure plate cylinder 47, and the slotting device 5 includes a second fixed block 55, a third Fixing block 512 and laser slotting equipment 514, collecting device 6 includes conveyer belt 61 and collecting box 68; The pushing device 3 is installed above the fixed frame 1, the fixing device 2 is installed above the pushing device 3, and the working platform 4 is installed in front of the pushing device 3 , a slotting device 5 is installed in front of the working platform 4, and a colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com