Longitudinal bar feeding assembly

A technology of longitudinal bars and components, applied in the direction of online network, household appliances, other household appliances, etc., can solve the problems of large operation volume and low efficiency of workers, and achieve the effect of improving production efficiency, reasonable structure and reducing manual work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

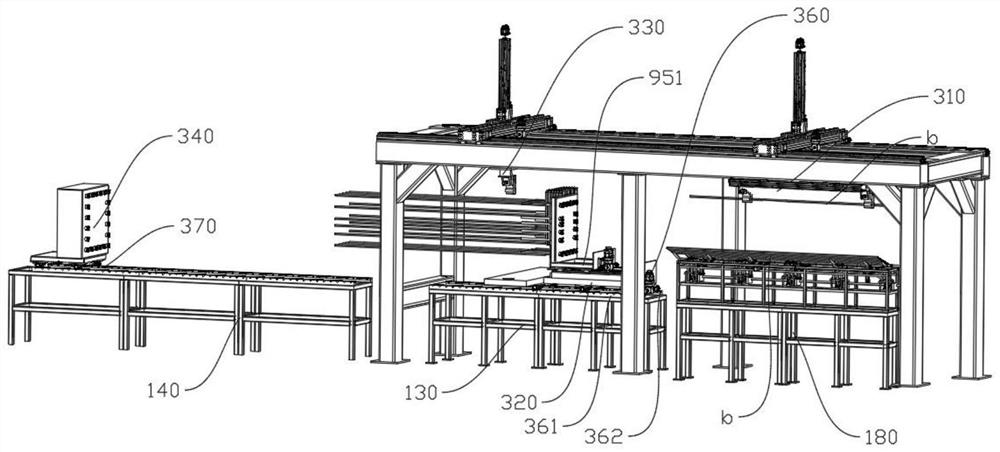

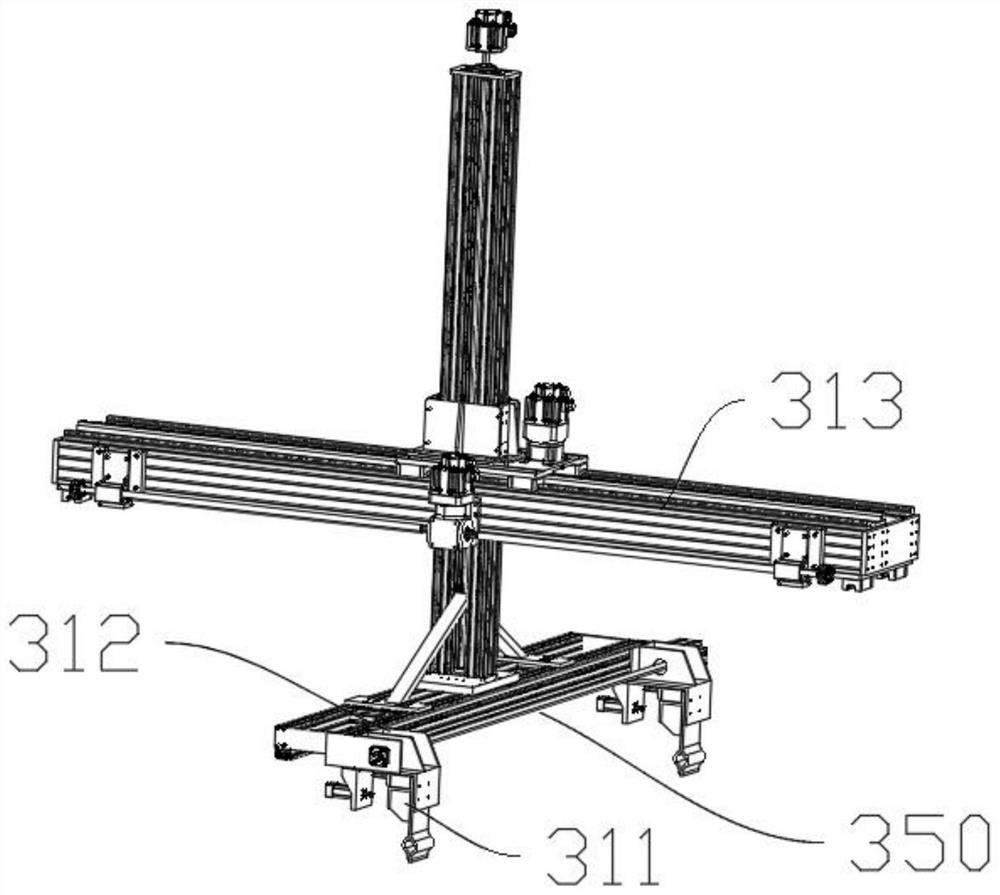

[0042] like Figure 1-12 As shown, the longitudinal rib feeding assembly of Embodiment 1 includes a frame, a longitudinal rib temporary placement rack 180, a longitudinal rib gripper 310 for grabbing the longitudinal rib b on the longitudinal rib temporary placement rack 180, and a longitudinal rib gripper 310 for placing stirrups The carrying platform 320, the longitudinal rib handle 330 and the longitudinal rib head end fixing member 340 of the material box 910, the longitudinal rib gripper 310, the carrying platform 320, the longitudinal rib receiver 330 and the longitudinal rib head end fixing member 340 are in sequence along the transmission direction of the longitudinal rib b. In the arrangement, the longitudinal rib temporary rack 180, the longitudinal rib gripper 310, the bearing platform 320, the longitudinal rib receiver 330 and the longitudinal rib head end fixing member 340 are all connected to the frame.

[0043] The longitudinal rib gripper 310 includes a grippin...

Embodiment 2

[0073] like Figure 13-17 As shown, Embodiment 2 is based on Embodiment 1, and the difference is that: the longitudinal reinforcement handle 330 includes a pick-up manipulator 331, a mechanical base 332 for installing the pick-up manipulator 331, and a driving mechanical base 332 between the bearing platform 320 and the reinforcement cage binding unit The reciprocating mechanical drive assembly 333 and the mechanical base 332 are fixedly connected with the mechanical drive assembly 333 .

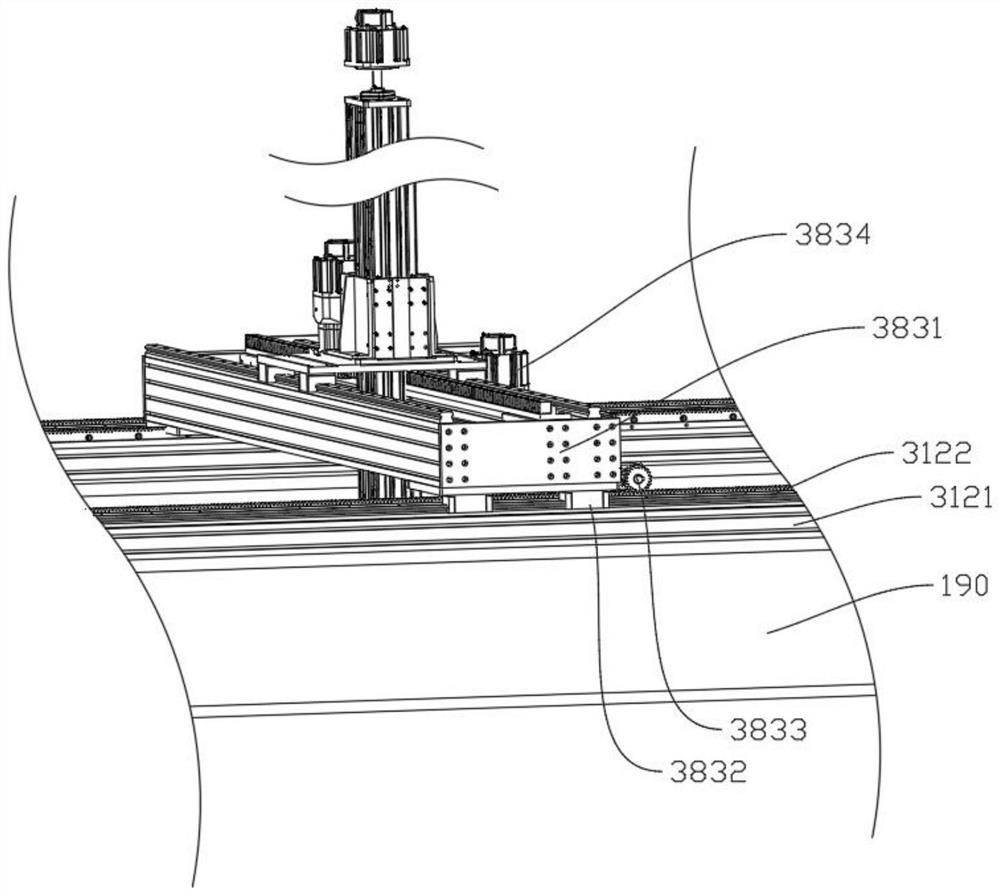

[0074] The mechanical drive assembly 333 includes a fourth drive assembly for driving the manipulator base 312 to move along the x-axis direction. The fourth drive assembly includes a fourth transverse frame 1831 and a fourth guide rail 1121 (with the first The guide rail 3121 is the same guide rail) and the fourth rack 1122 (the same rack as the first rack 3122 ), the fourth slider 1832 fixed on the fourth horizontal frame The fourth gear 1833, the fourth motor 1834 for driving the fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com