Heavy road lifting method based on multi-stage composite telescopic hydraulic cylinder

A technology of telescopic hydraulic cylinder and two-stage cylinder, which is applied in the direction of lifting device, fluid pressure actuating device, etc., can solve the problems of affecting the lifting work efficiency, slow extension speed, vibration and impact, etc. The impact frequency of level change and the effect of increasing the expansion and contraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

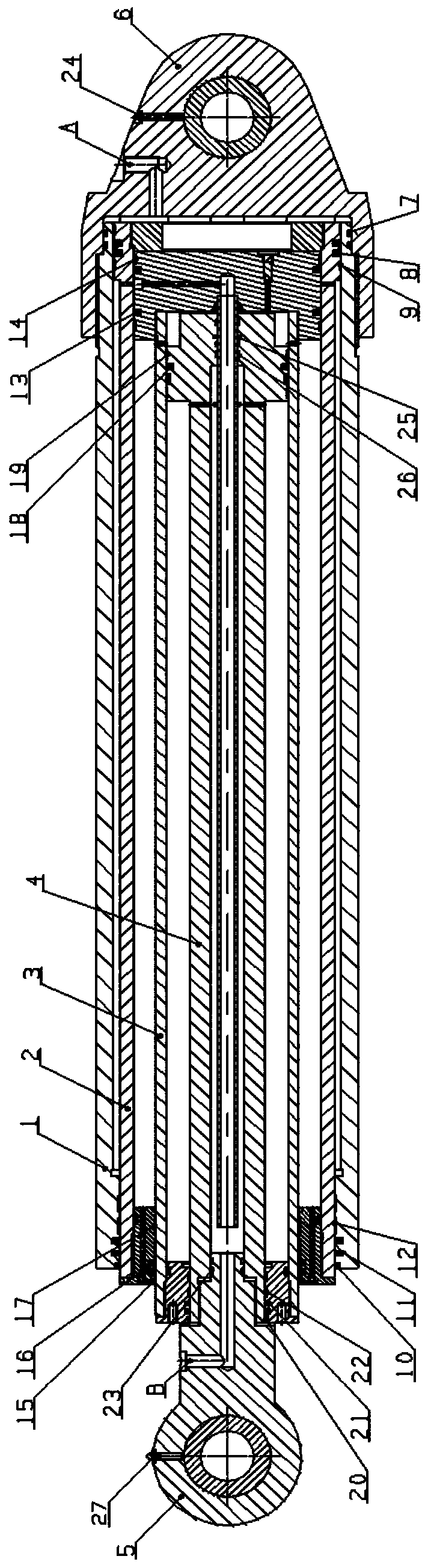

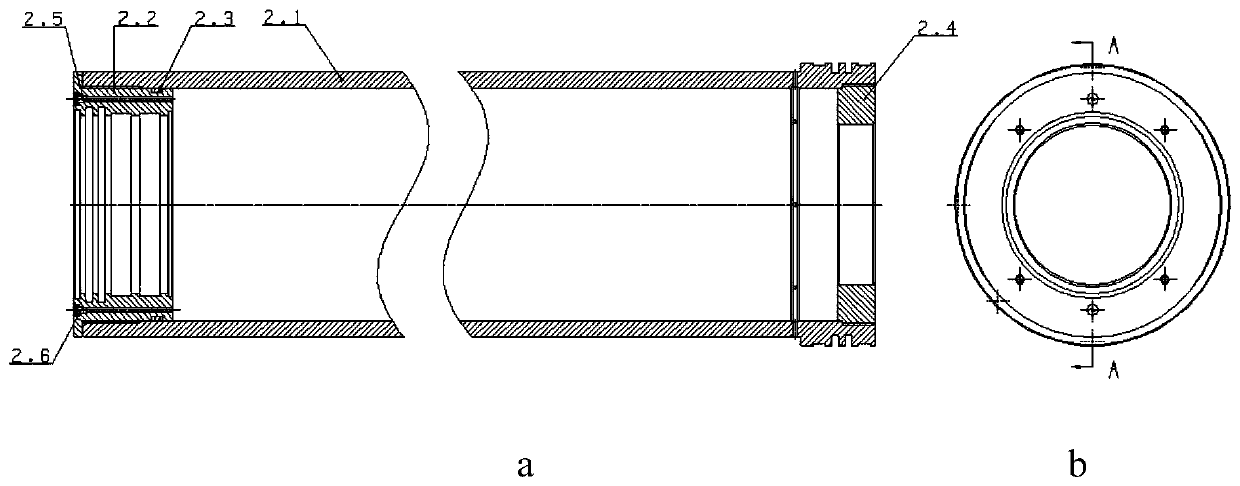

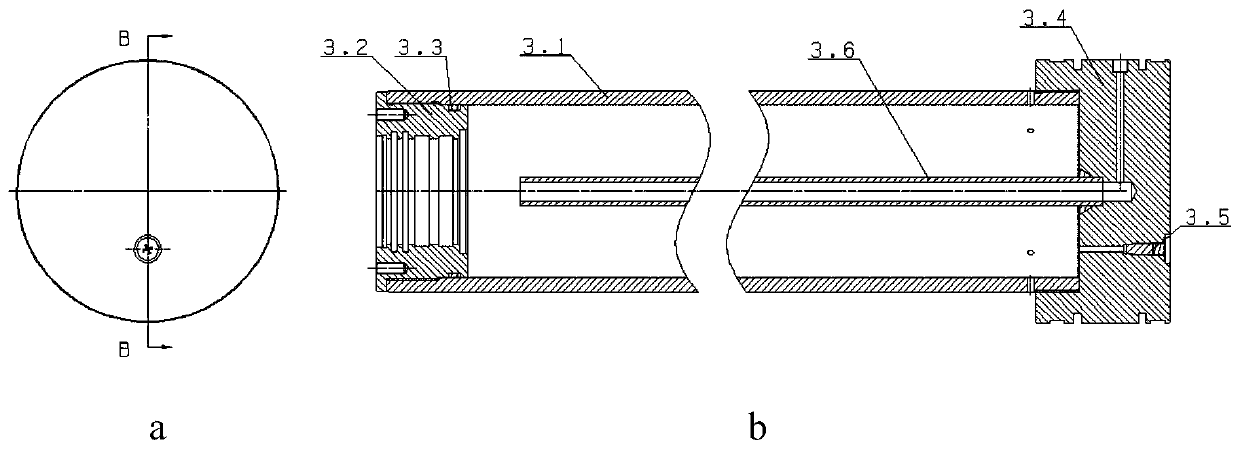

[0029] The present invention provides a heavy-duty lifting method based on a multi-stage composite telescopic hydraulic cylinder, which is realized based on a multi-stage composite telescopic hydraulic cylinder, such as figure 1As shown, the multi-stage composite telescopic hydraulic cylinder is designed to include cylinder barrel 1, first-stage cylinder 2, second-stage cylinder 3, third-stage cylinder 4, cylinder head 5, cylinder bottom 6 and O-rings of different specifications, lattice Lay ring, guide ring, dust ring and oil cup, of which:

[0030] The cylinder 1, the first-stage cylinder 2, the second-stage cylinder 3 and the third-stage cylinder 4 are sequentially nested from the outside to the inside. The cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com