A self-repairing rodent-proof and termite-proof polyurethane, preparation method and application

A self-repairing and polyurethane technology, which is applied in the field of preparation and self-repairing anti-rodent and ant-proof polyurethane, can solve the problems of poor anti-rodent and ant-proof polyurethane anti-rodent and ant-proof effects, etc., achieve good anti-rodent and ant-proof effects, improve service life, The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

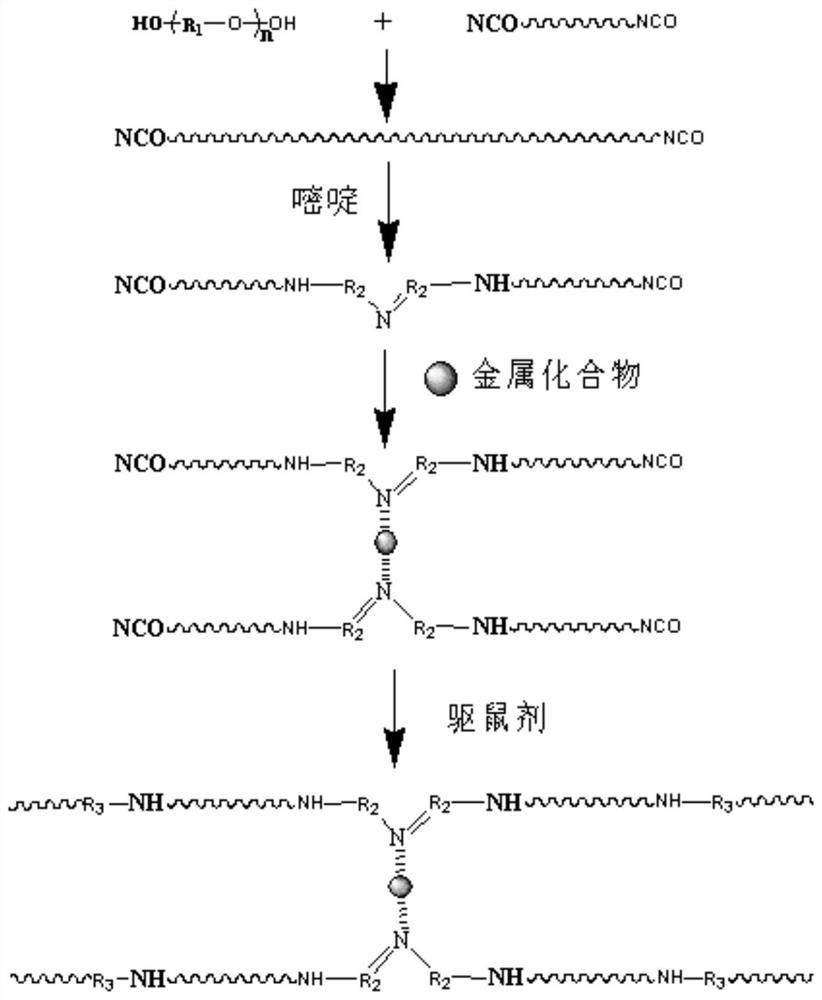

Method used

Image

Examples

Embodiment 1

[0030] (1) Synthesis of polyurethane prepolymer:

[0031] Under the protection of nitrogen, 46g of PTMG was dehydrated at 110°C for 1h under the condition of vacuum degree ≤0.1MPa, cooled to 60°C, added 22g of IPDI (isophorone diisocyanate) and 0.1g of stannous octoate, and reacted for 1h to obtain polyurethane pre- Polymer;

[0032] (2) Synthesis of self-repairing anti-rodent and ant-proof polyurethane:

[0033] (21) Add 10g of 4,6-dihydroxypyrimidine and 10ml of N-methylpyrrolidone sequentially into the reactor, and react at 60°C for 3h;

[0034] (22) Add 6g of nickel chloride hexahydrate to the reactor, keep it warm at 60°C for 1h, then add 1g of phenylthiourea, and react at 50°C for 1h;

[0035] (23) Desolventization is obtained from repairing rodent-proof and termite-proof polyurethane.

[0036] The self-healing efficiency and anti-rodent and ant-proof properties of the prepared self-repairing rodent-proof and termite-proof polyurethane were tested respectively.

[00...

Embodiment 2

[0059] (1) Synthesis of polyurethane prepolymer:

[0060] Under the protection of nitrogen, 50g of PCL was dehydrated at 115°C for 2 hours under the condition of vacuum degree ≤ 0.1MPa, cooled to 80°C, and then 25g of MDI (4,4-diphenylmethane diisocyanate) and 0.1g of stannous octoate were added successively, and the reaction 2h, obtain polyurethane prepolymer;

[0061] (2) Synthesis of self-repairing anti-rodent and ant-proof polyurethane:

[0062] (21) Add 12g of 4,6-dihydroxypyrimidine and 10ml of tetrahydrofuran to the reactor successively, and react at 80°C for 4h;

[0063] (22) Add 6g of nickel chloride hexahydrate to the reactor, keep it warm at 80°C for 2h, add 0.8g of capsaicin, and react at 90°C for 2h;

[0064] (23) Desolventization is obtained from repairing rodent-proof and termite-proof polyurethane.

[0065] The repair efficiency of the obtained product is 72%, the tensile strength is 5.0 MPa, and the elongation at break is 750%.

[0066] After anti-rat and ...

Embodiment 3

[0069] (1) Synthesis of polyurethane prepolymer:

[0070] Under the protection of nitrogen, dehydrate 55g of PPG at 120°C for 3 hours under the condition of vacuum degree ≤ 0.1MPa, cool down to 90°C, add 18g of TDI (toluene diisocyanate) and 0.1g of stannous octoate, and react for 3 hours to obtain a polyurethane prepolymer;

[0071] (2) Synthesis of self-repairing anti-rodent and ant-proof polyurethane:

[0072] (21) Add 8g of 4,6-dihydroxypyrimidine and 10ml of oxane to the reactor successively, and react at 90°C for 5h;

[0073] (22) Add 7g of nickel chloride hexahydrate to the reactor, keep warm at 90°C for 3h, add 0.8g of phenylthiourea, and react at 100°C for 3h;

[0074] (23) Desolventization is obtained from repairing rodent-proof and termite-proof polyurethane.

[0075] The repair efficiency of the obtained product is 70%, the tensile strength is 4.8 MPa, and the elongation at break is 850%.

[0076] After anti-rat and ant-proof tests, it was found that there were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com