Chitosan/poly(acrylamide-acrylic acid)-Al3+ ionized hydrogel as well as preparation method and application thereof

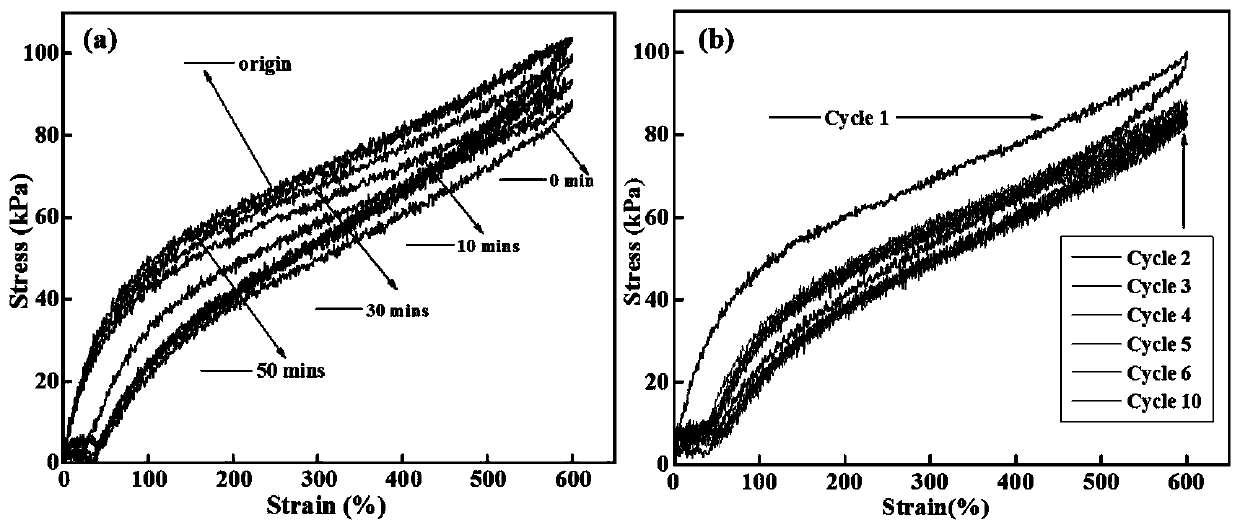

A technology of acrylamide and chitosan, which is applied in application, diagnostic recording/measurement, diagnosis, etc., can solve the problems of insufficient strength, poor self-healing and fatigue resistance, and achieve good fatigue resistance, mechanical performance improvement, fast The effect of fully self-healing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

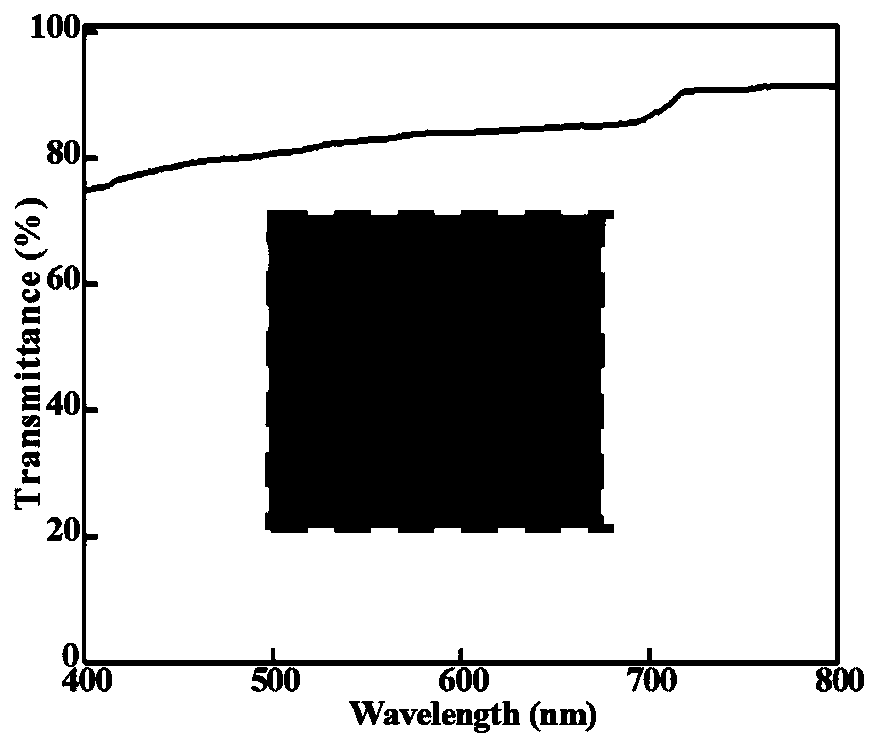

[0041] Chitosan / poly(acrylamide-acrylic acid)-Al of the present embodiment 3+ (CPA) The preparation method of ionic hydrogel, comprises the steps:

[0042] (1) Add 0.3g chitosan (CS) to 10mL, Al 3+ AlCl with a concentration of 0.075mol / L 3 aqueous solution, and then the resulting mixture was continuously stirred at 90 °C for 90 min to ensure one-step dissolution and crosslinking of CS to form Al 3+ / CS complex solution.

[0043] (2) the Al obtained in step (1) 3+ / CS complex solution was cooled to 60°C, then acrylamide, acrylic acid and 0.04g of 2-hydroxy-2-methylacetophenone were added to the above solution in turn, and stirred at 60°C until all reactants were dissolved to obtain a mixed solution; wherein: the concentration of the acrylamide in the mixed solution is 4mol / L; the concentration of the acrylic acid in the mixed solution is 0.2mol / L.

[0044] (3) Finally, inject the mixed solution obtained in step (2) into a transparent mold, and polymerize for 1 h under an u...

Embodiment 2

[0046] Chitosan / poly(acrylamide-acrylic acid)-Al of the present embodiment 3+ (CPA) The preparation method of ionic hydrogel, comprises the steps:

[0047] (1) Add 0.2g chitosan (CS) to 10mL, Al 3+ AlCl with a concentration of 0.1mol / L 3 aqueous solution, and then the resulting mixture was continuously stirred at 80 °C for 120 min to ensure one-step dissolution and crosslinking of CS to form Al 3+ / CS complex solution.

[0048] (2) the Al obtained in step (1) 3+ / CS complex solution was cooled to 40°C, then acrylamide, acrylic acid and 0.04g of 2-hydroxy-2-methylacetophenone were added to the above solution in turn, and stirred at 40°C until all reactants were dissolved to obtain a mixed solution; wherein: the concentration of the acrylamide in the mixed solution is 3mol / L; the concentration of the acrylic acid in the mixed solution is 0.6mol / L.

[0049] (3) Finally, inject the mixed solution obtained in step (2) into a transparent mold, and polymerize for 1 h under an ul...

Embodiment 3

[0051] Chitosan / poly(acrylamide-acrylic acid)-Al of the present embodiment 3+ (CPA) The preparation method of ionic hydrogel, comprises the steps:

[0052] (1) Add 0.5g chitosan (CS) to 10mL, Al 3+ AlCl with a concentration of 0.125mol / L 3 aqueous solution, and then the resulting mixture was continuously stirred at 100 °C for 180 min to ensure one-step dissolution and crosslinking of CS to form Al 3+ / CS complex solution.

[0053] (2) the Al obtained in step (1) 3+ / CS complex solution was cooled to 40°C, then acrylamide, acrylic acid and 0.06g of 2-hydroxy-2-methylacetophenone were added to the above solution in sequence, and stirred at 40°C until all reactants were dissolved to obtain a mixed solution; wherein: the concentration of the acrylamide in the mixed solution is 3mol / L; the concentration of the acrylic acid in the mixed solution is 0.3mol / L.

[0054] (3) Finally, the mixed solution obtained in step (2) was injected into a transparent mold, and polymerized under...

PUM

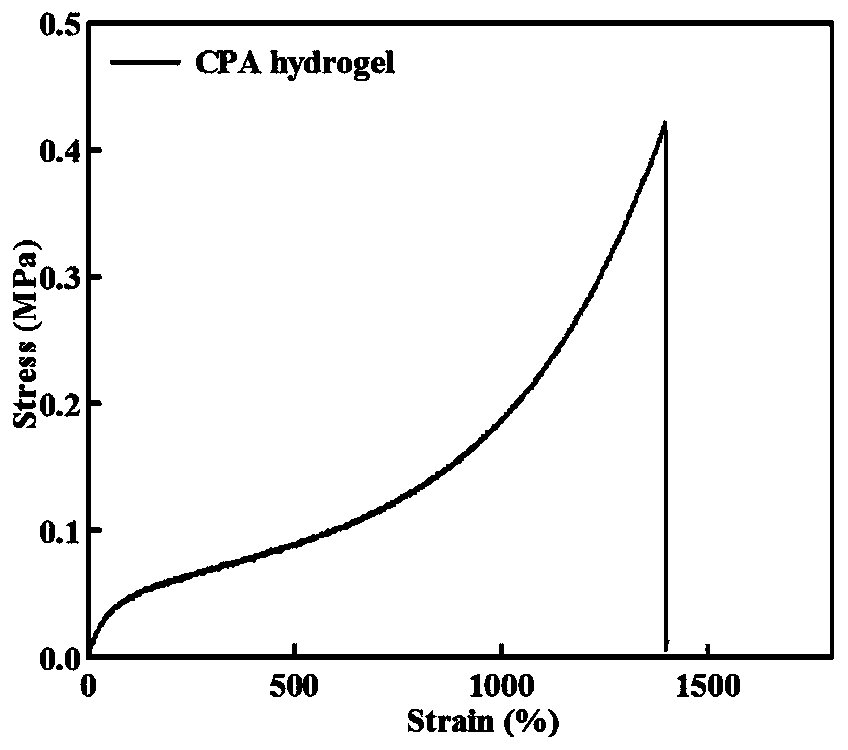

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com