Flame-retardant polyamide compositions

一种组合物、聚酰胺的技术,应用在阻燃的聚酰胺组合物领域,能够解决能源密集型不利等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

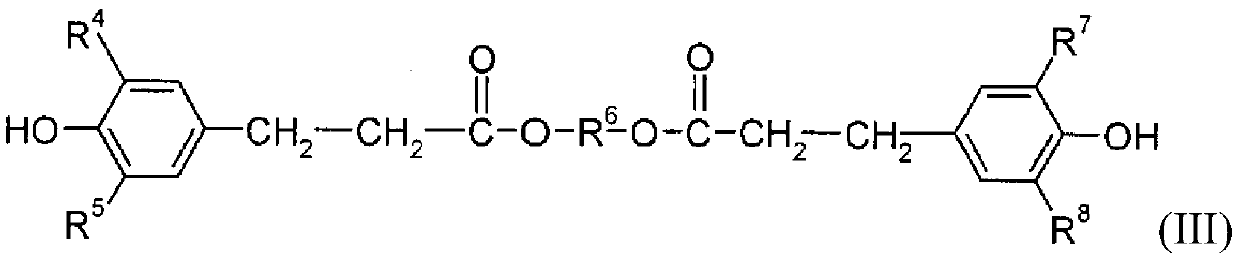

Image

Examples

example

[0213] The components indicated in Table 1 were mixed in a ZSK 26 compounder twin-screw extruder from Coperion Werner & Pfleiderer (Stuttgart, Germany) at a temperature of about 280°C. Mix, drain into water bath as a strand, cool until ready to pellet and granulate. The pellets were dried to constant weight in a vacuum oven at 70°C.

[0214] These pellets were then processed on an Arburg A470 injection molding machine at a melting temperature ranging from 270°C to 290°C and a tool temperature ranging from 80°C to 100°C to produce test pieces with dimensions 80mm x 10mm x 4mm Samples and circular plates with a diameter of 80mm and a thickness of 0.75mm, 1.5mm or 3mm.

[0215] The mechanical properties of the products produced from the compositions according to the invention were determined in the bending test according to ISO 178 and in the Izod impact test according to ISO 180 / 1U.

[0216] Glow-wire resistance is determined according to IEC 60695-2-12 by means of the glow-wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com