Secondary Grouting Method for Shield Construction

A secondary grouting and grouting technology, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve problems such as large quality and safety risks, insufficient grouting volume, difficult grout injection, etc., and reduce the risk of shield tunneling construction , the effect of avoiding safety and quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

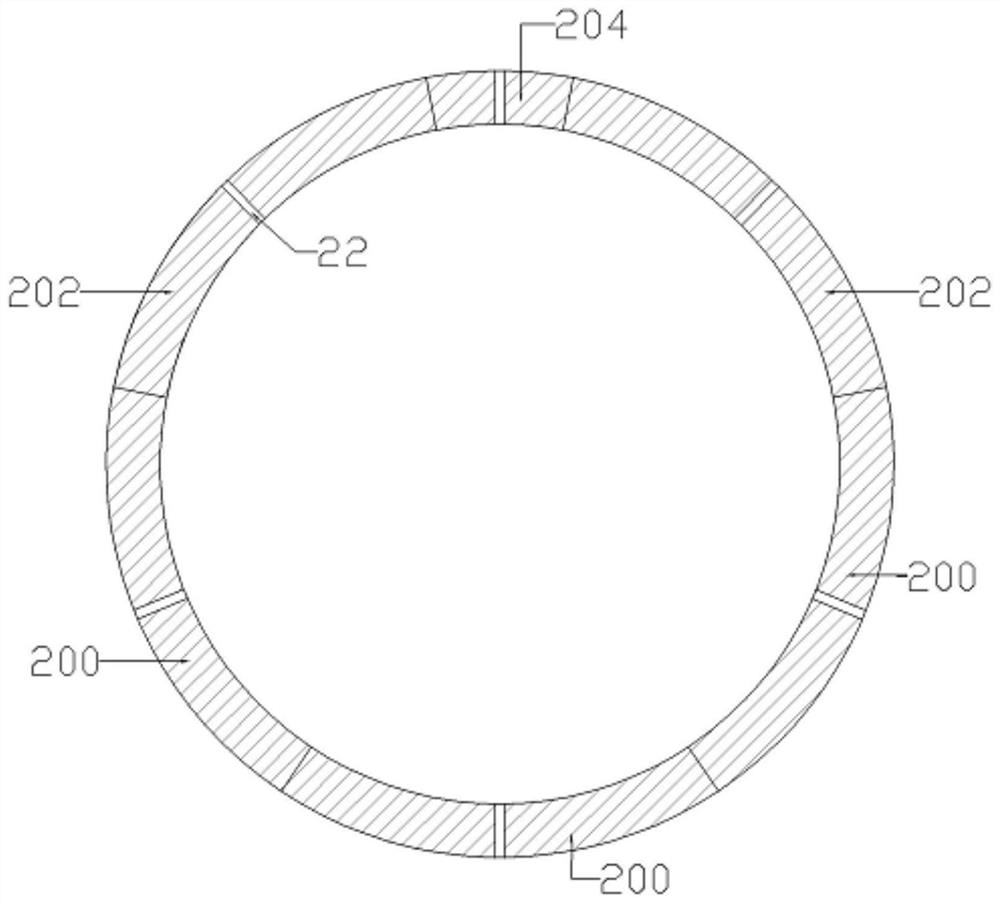

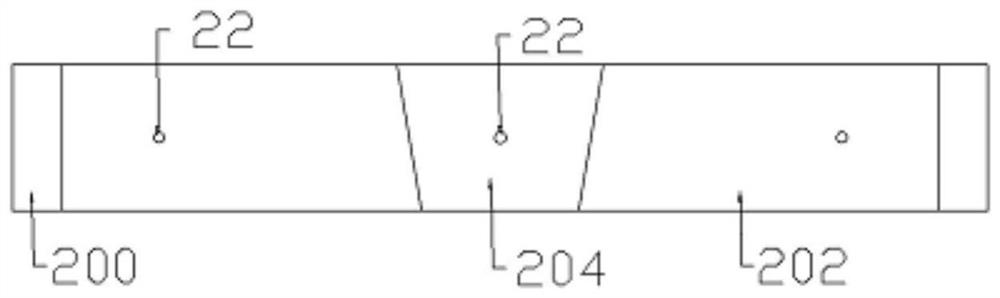

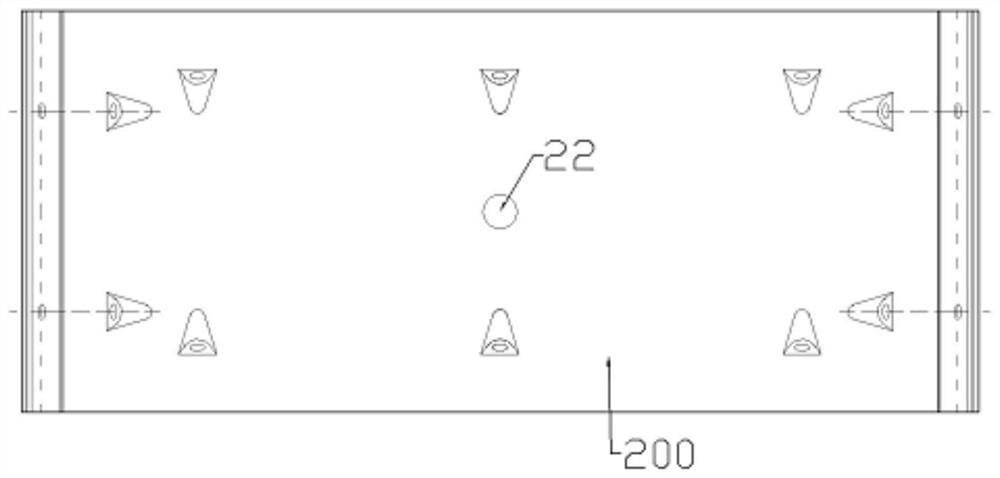

[0032] For ease of understanding, a brief description of the tunnel and its pipe rings and segments is given first. see Figure 1-3 , the tunnel is composed of pipe rings assembled from segments after shield tunneling, and each segment is provided with a reserved hole 22 for grouting. In a typical tunnel, each pipe ring of the tunnel is composed of three standard blocks 200, two adjoining blocks 202 and one capping block 204, a total of six segments are assembled, and each segment is provided with a note Slurry is with reserved hole 22.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com