U-shaped steel support double-groove clamping plate anti-skid anti-snap safety clamp set and installation method

A technology of clamping cables and section steel, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., and can solve problems such as insufficient support resistance, breakage, misaligned sliding nuts or screws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

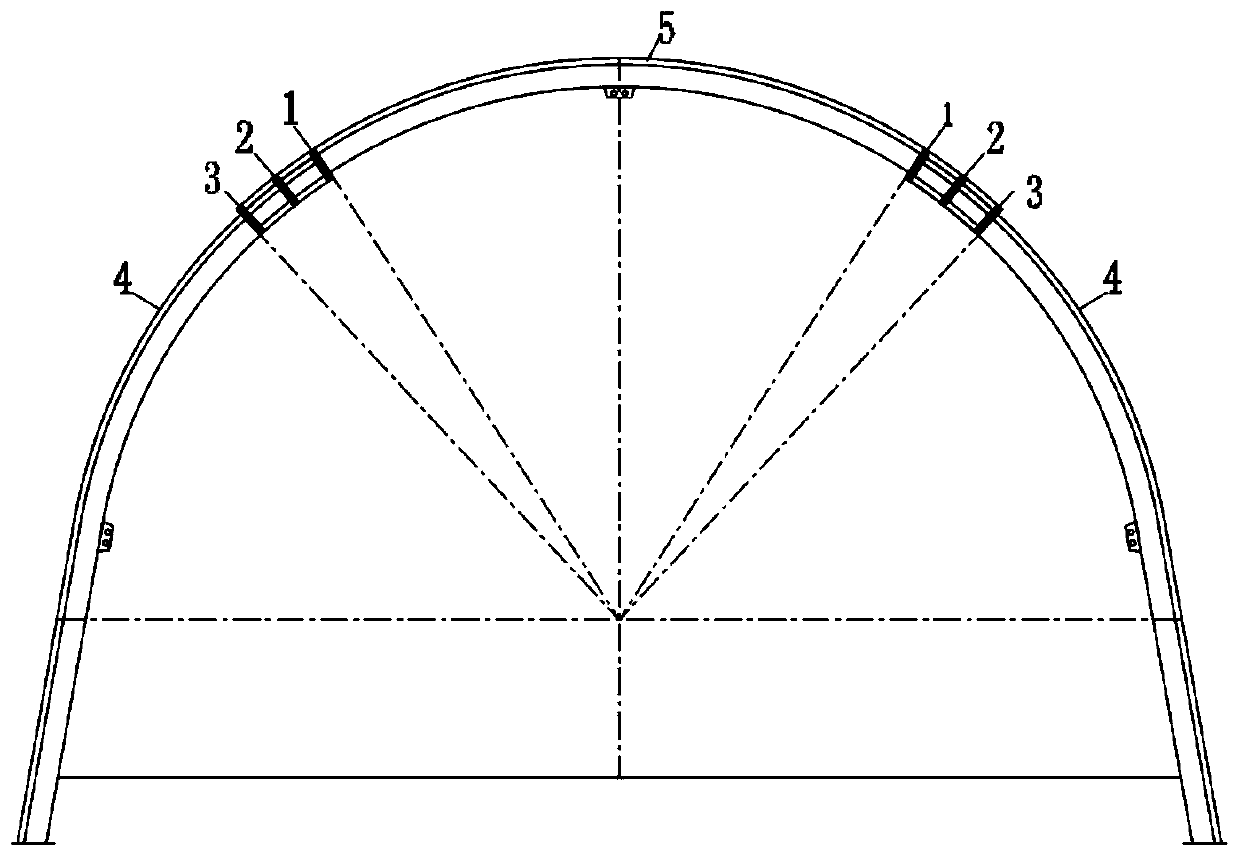

[0018] A U-shaped steel shed double-groove splint anti-slip and anti-break safety cable set, which includes: upper limit clamp cable 1, middle unlimited clamp cable 2 and lower limit clamp cable 3; upper limit clamp cable 1, middle limit clamp cable 2 and the lower limit card cable 3 are respectively installed in the upper, middle and lower three positions of the U-shaped steel shed lap joint.

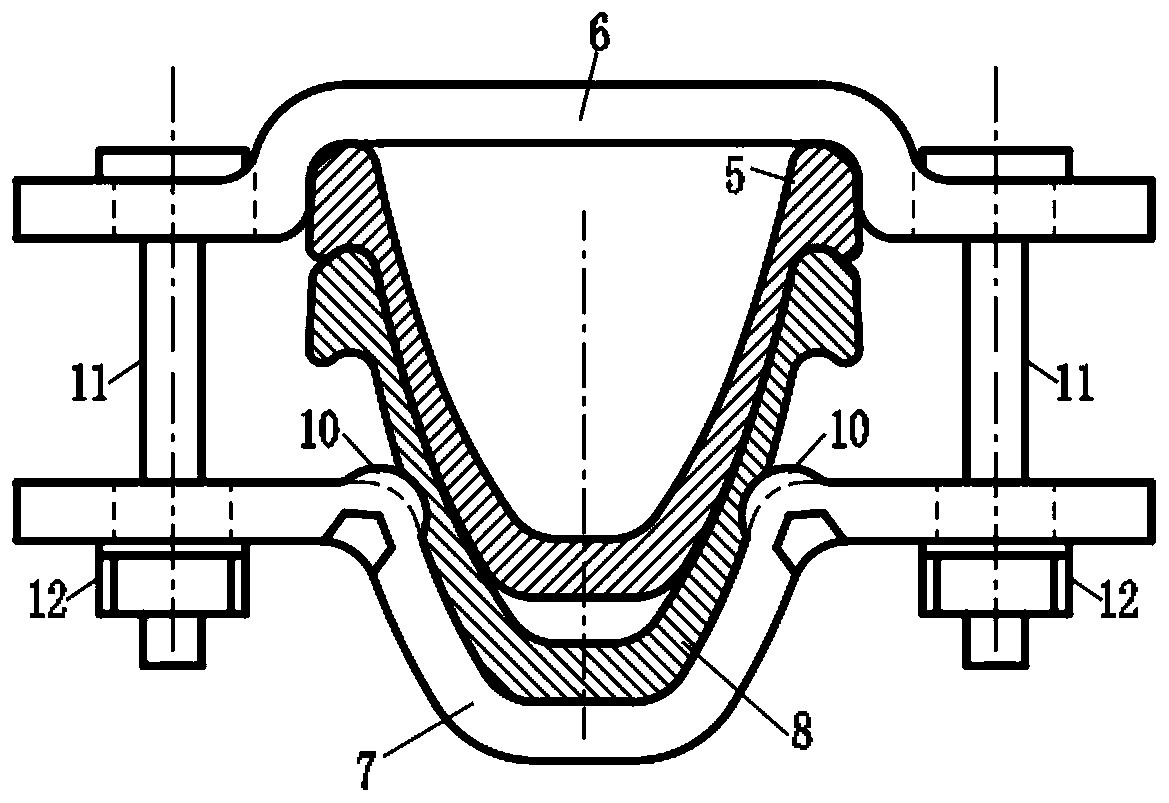

[0019] The middle unlimited clamp cable 2 includes an upper web 6 and a lower web 7, and the upper web 6 and the lower web 7 are fixedly connected by bolts 11; the U-shaped steel shed support column leg 4 is fixed in the U-shaped groove of the lower web 7, The U-shaped shed roof beam 5 is fixed between the U-shaped groove of the U-shaped steel shed support column leg 4 and the upper web 6 .

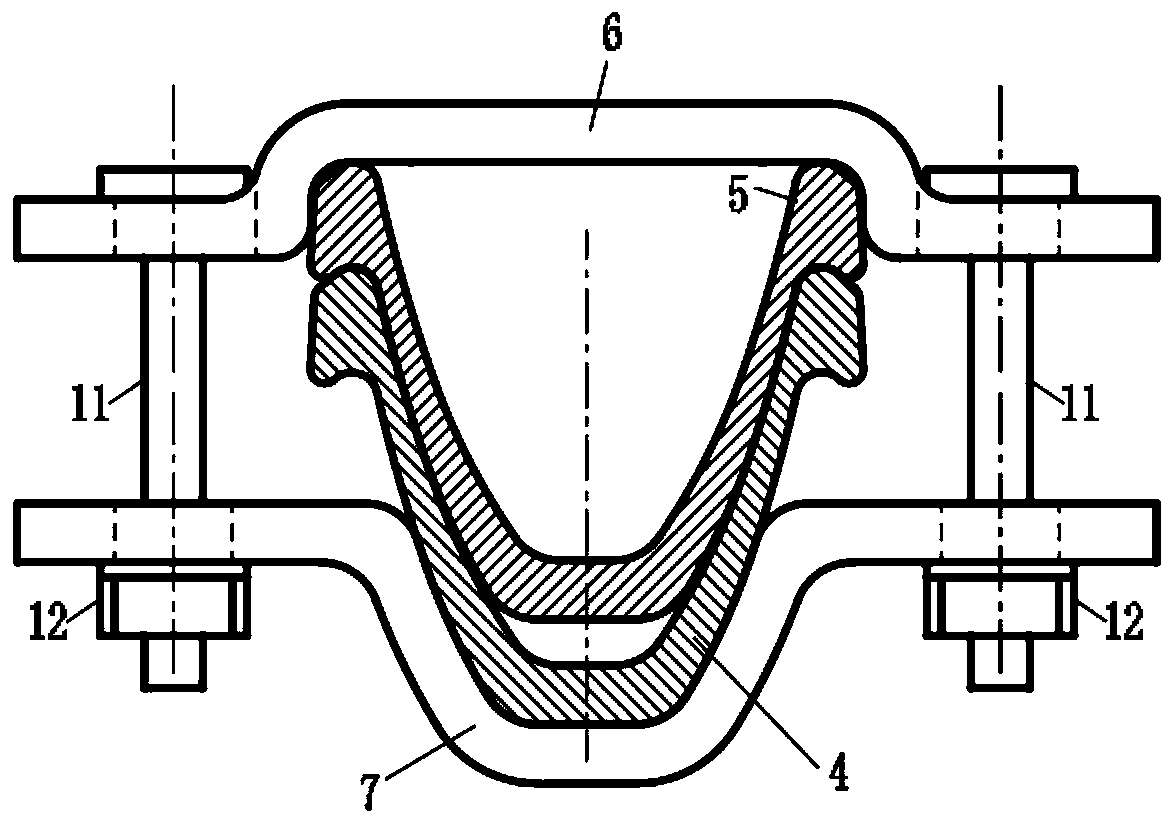

[0020] The lower limit card cable 3 includes an upper web 6 and a lower web 7, and the upper web 6 and the lower web 7 are fixedly connected by bolts 11; the U-shaped steel shed support column leg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com