A three-shoe drum brake mechanism

A brake mechanism and brake shoe technology, which is applied in the field of vehicle engineering, can solve problems such as uneven wear of brake shoes and easy fatigue damage of the actuating mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

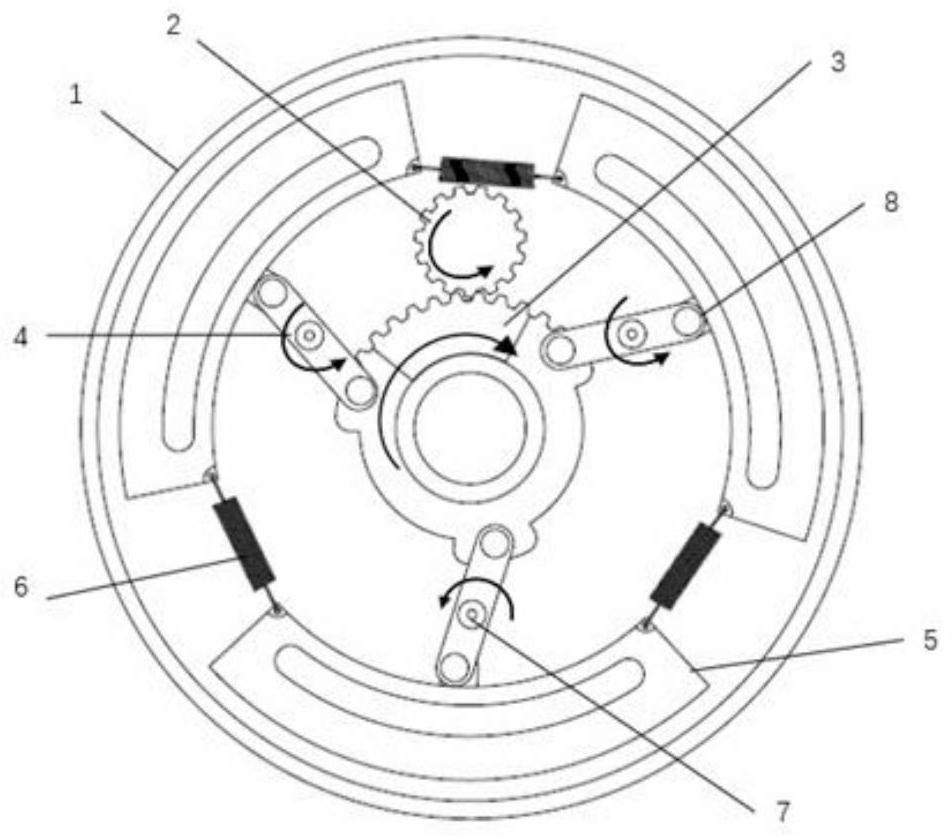

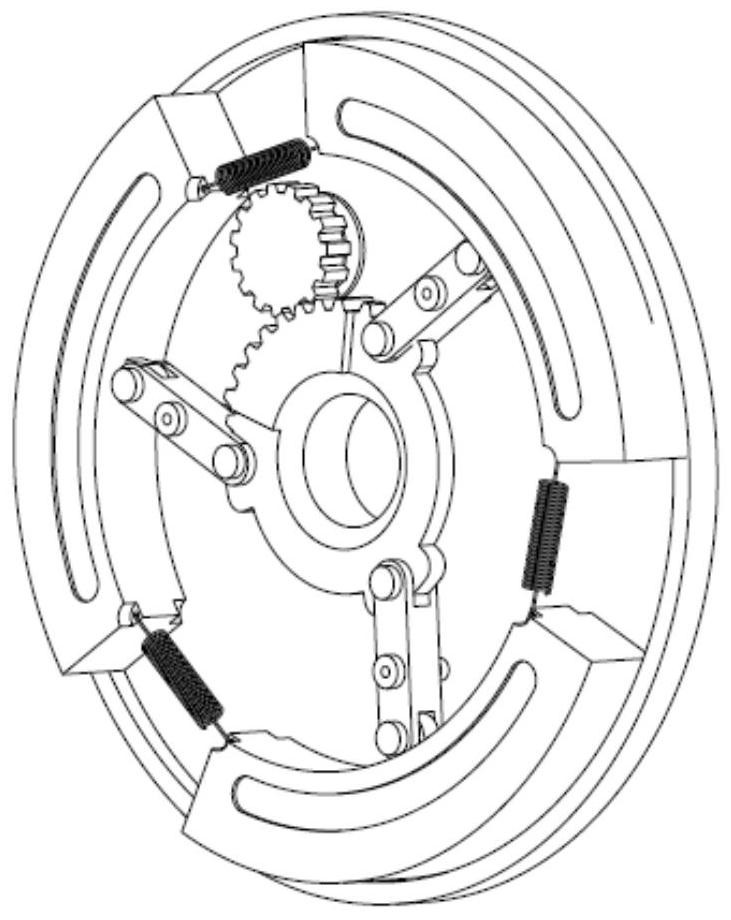

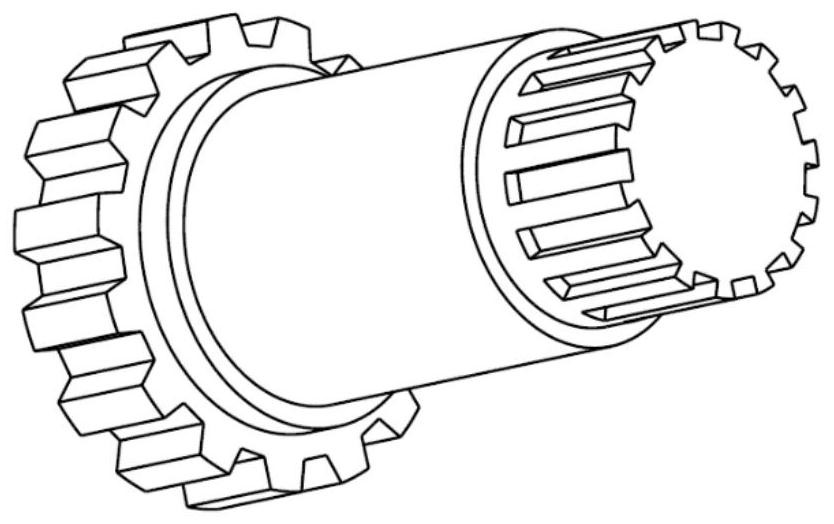

[0024] A three-brake shoe-drum brake mechanism, such as Figure 1-4 shown. The brake mechanism includes a casing 1, a drive gear shaft 2, a central special-shaped gear 3, a connecting arm 4, a brake shoe 5, a restoring spring 6, a fixed shaft pin 7 and a connecting pin 8; connecting arm 4, a braking shoe 5, and a restoring spring 6 and fixed shaft pin 7 are provided with three respectively, and there are six connecting pins 8; the outline of the shell 1 is a regular geometric shape, and its inner wall is provided with a drive gear shaft hole, a central shaft hole and a fixed shaft pin mounting hole; the outer edge of the shell 1 Three brake shoes 5 are evenly arranged, and two adjacent brake shoes 5 are connected by a return spring 6; a drive gear shaft 2 is arranged in the drive gear shaft hole, and the drive gear shaft 2 is arranged in the brake shoe 5 to drive The axis of the gear shaft 2 is set eccentrically with the axis of the housing 1, and the driving gear shaft 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com