Pneumatic forcedly-sealing tapered plug type powdered coal feeding reversing valve

A technology of forced sealing and reversing valve, applied in valve details, multi-port valve, valve device and other directions, can solve the problem that the sealing effect is difficult to meet the ideal requirements, achieve less difficulty in processing and assembly, ensure high reliability, and facilitate disassembly and assembly maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

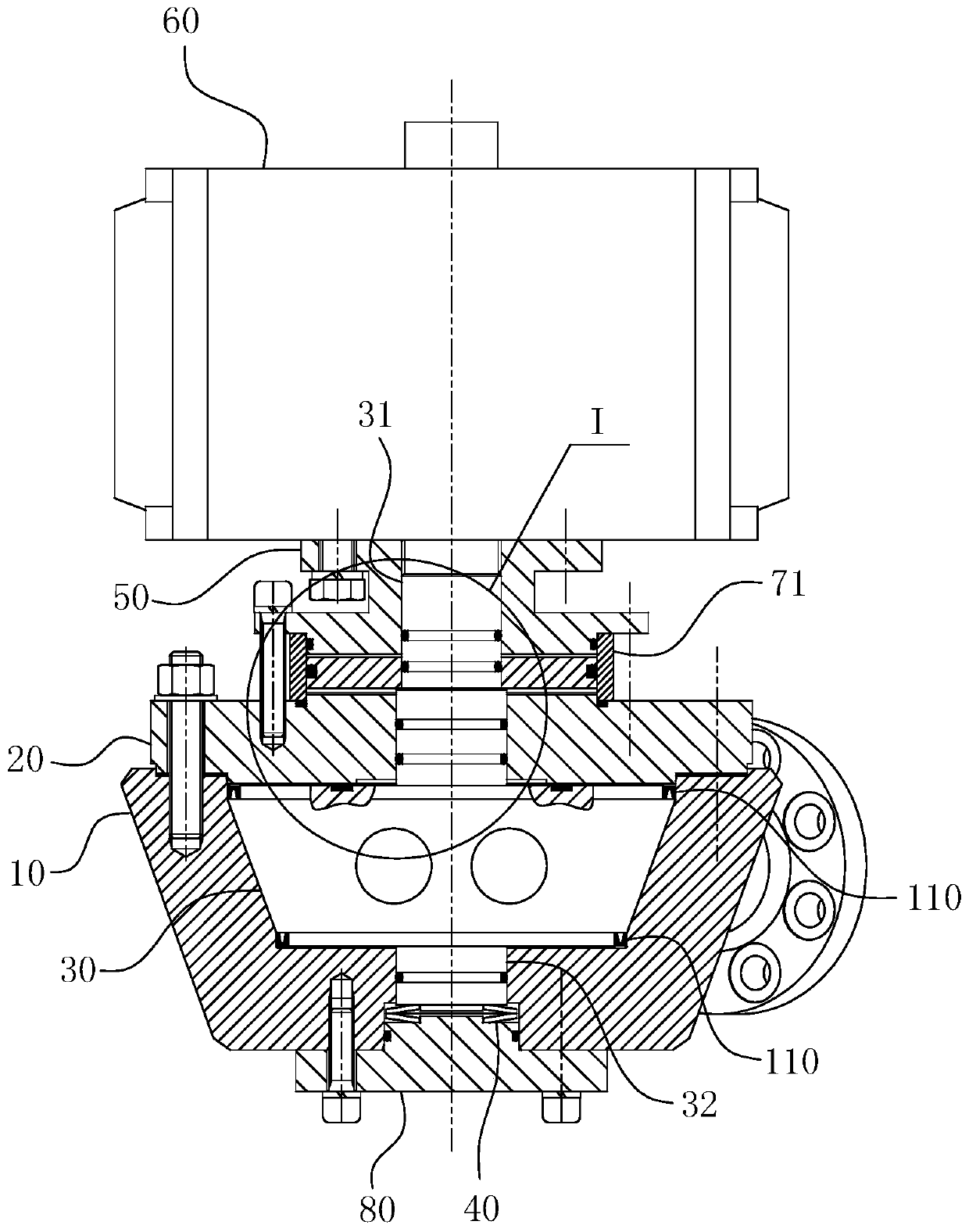

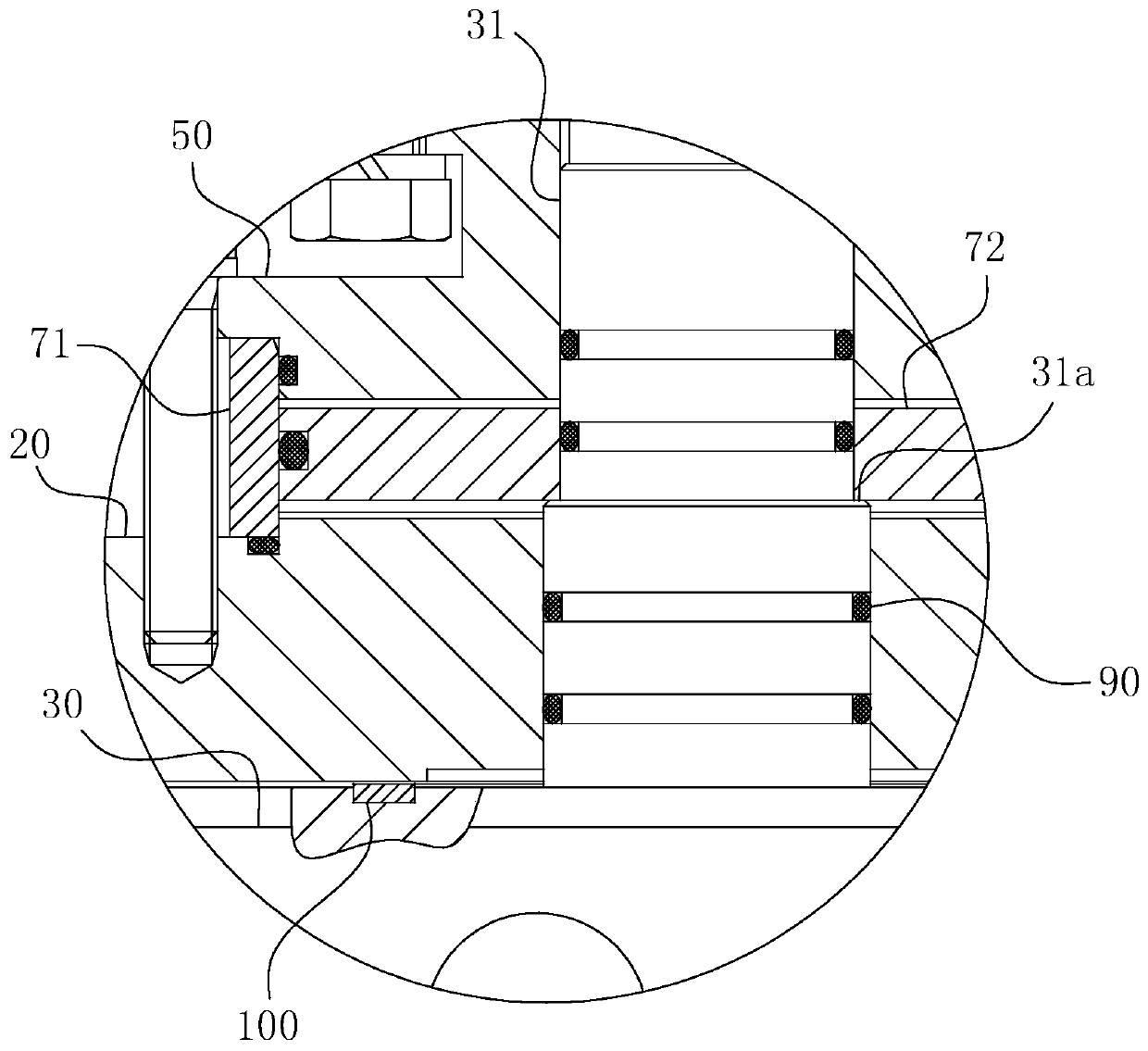

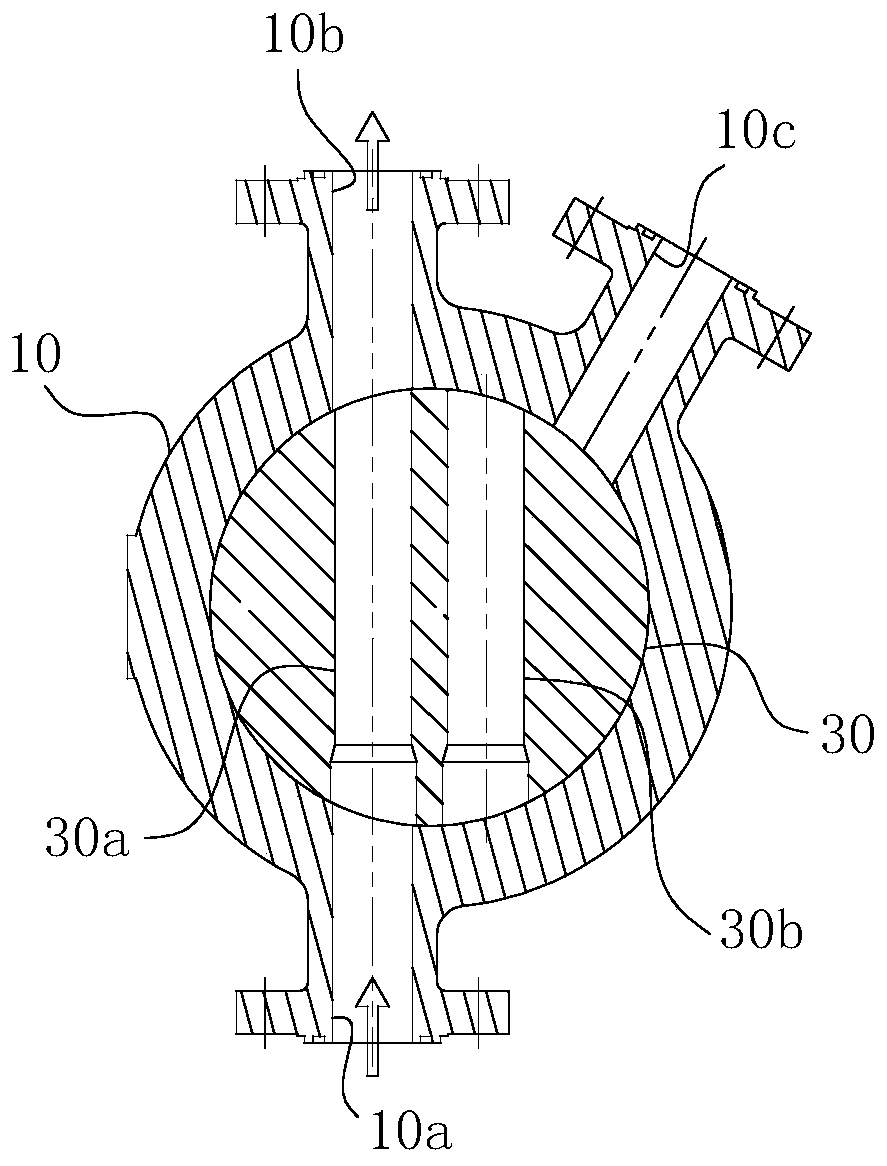

[0039] The concrete implementation structure of the present invention can refer to Figure 1-2 As shown, it includes a gland 80, a compression spring 40, a valve body 10, a cock 30, a valve cover 20, a compression ring 72, a sealing ring body 71, a bracket 50 and a pneumatic actuator arranged in sequence from bottom to top along the vertical line. device 60.

[0040] Pneumatic actuator 60 is available in the market. It is an actuator that uses air pressure to drive the opening and closing or regulating valves. It is also called a pneumatic actuator or a pneumatic device, but it is generally called a pneumatic head. The function in the present invention is to drive the cock 30 to rotate at a certain angle according to a predetermined direction, so as to realize the opening and closing function of the valve circuit. In actual operation, it sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com