Valve core seat fixing structure of extraction type faucet, and extraction type faucet

A technology of fixed structure and valve core seat, applied in the field of bathroom, can solve the problems of weak strength and easy to fall off, lower product qualification rate, weak load-bearing capacity of valve core seat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

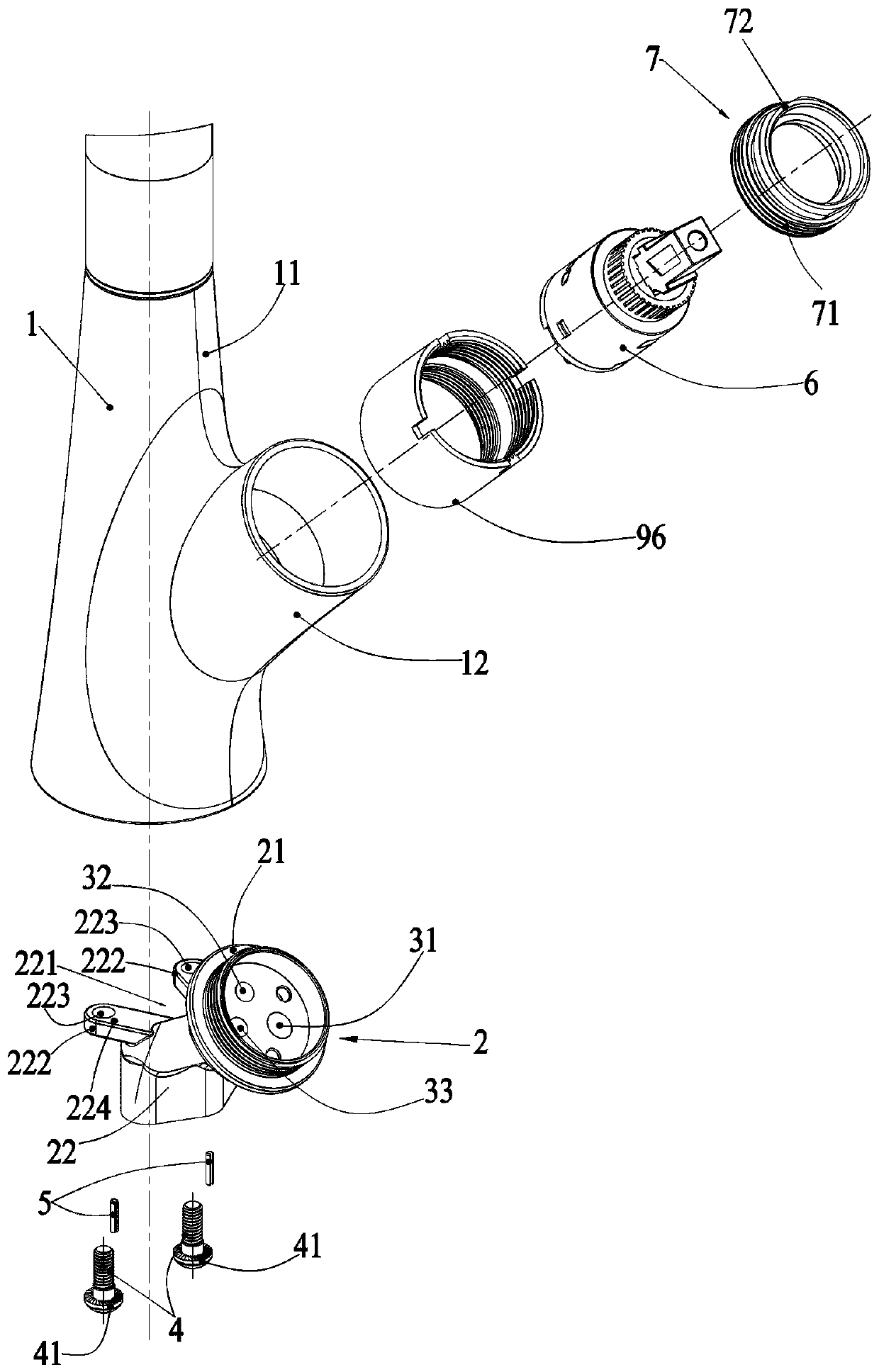

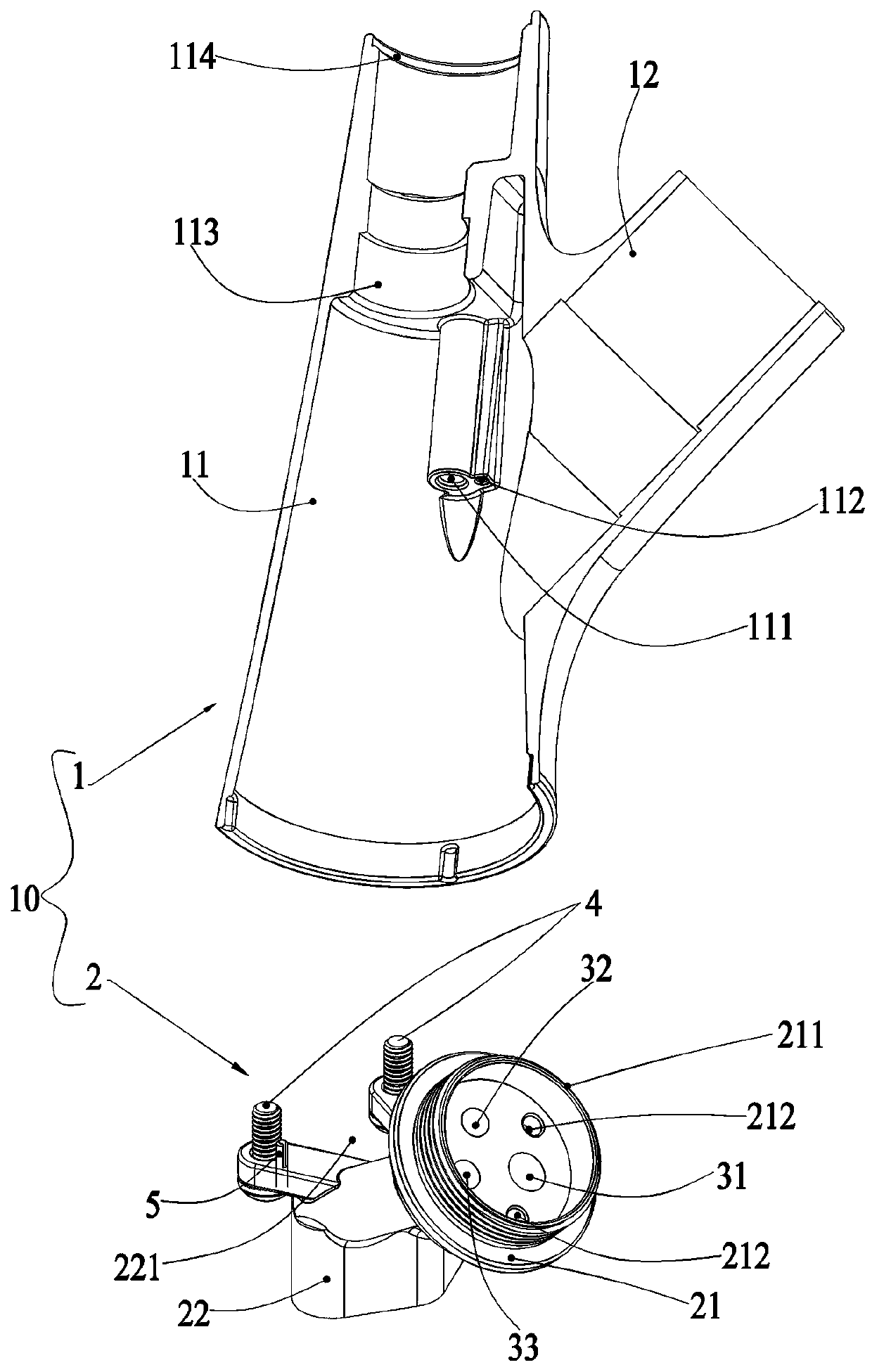

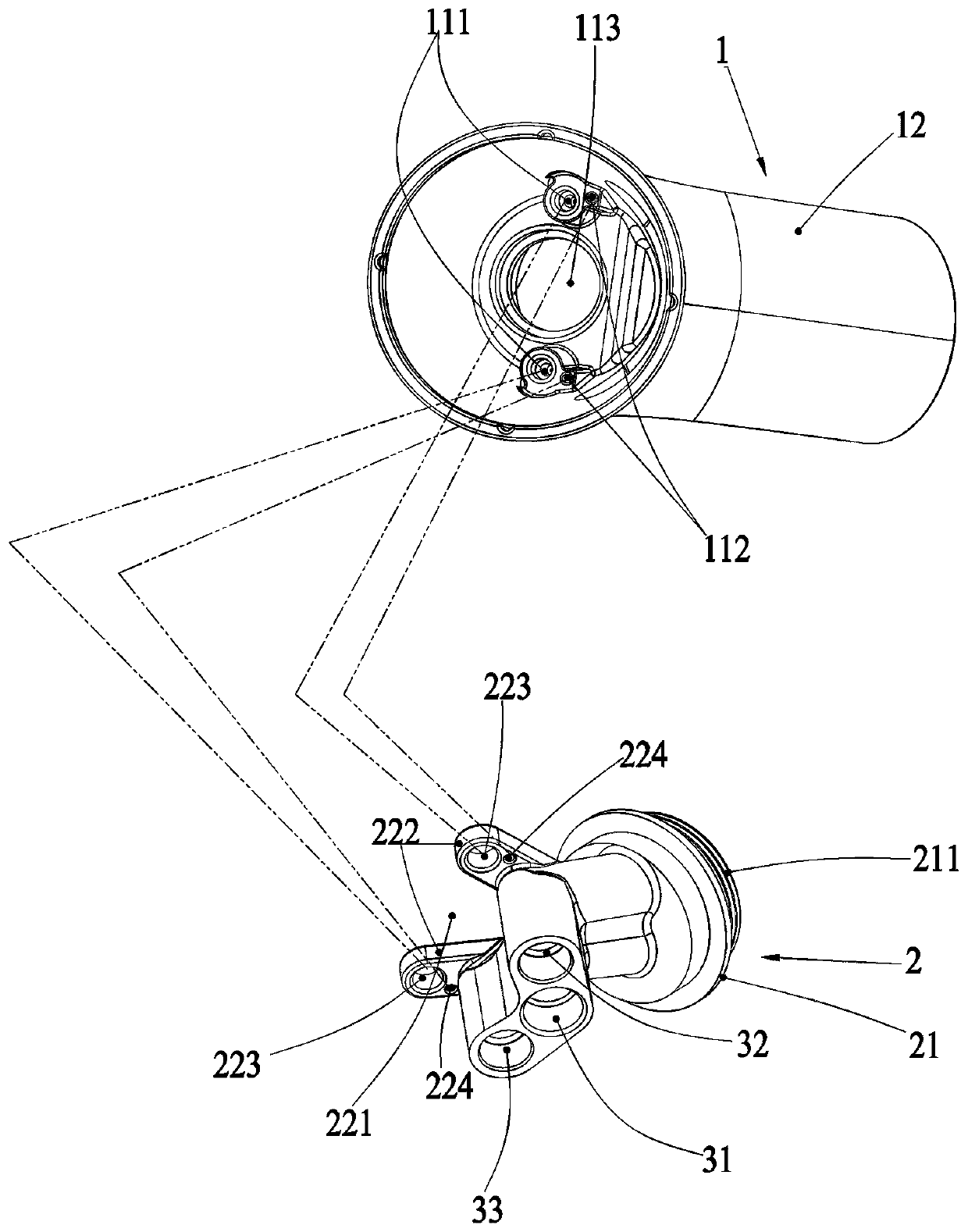

[0030] Such as Figure 1 to Figure 7 As shown, a valve core seat fixing structure 10 of a withdrawable faucet is composed of a faucet body 1 and a valve core seat 2 of a withdrawable faucet. The valve core assembly pipe 12 is composed of the valve core assembly pipe 12 branched outward from the side wall of the through pipe 11 in the main body; the valve core seat body 2 is composed of a valve core seat 21 and a fixed seat 22 integrated with the valve core seat 21, the valve core seat 21 and the fixed seat The angle formed by 22 is consistent with the angle formed by the through pipe 11 in the main body and the valve core assembly pipe 12. The inside of the valve core seat 2 is provided with three mutually independent water channels 31, 32, 33, wherein 31 is a water outlet channel, and 32 , 33 are water inlet passages, and water passages 31, 32, 33 pass through to the fixed seat 22 along the valve core seat 21, and a relief part 221 is formed between the fixed seat 22 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com