Contact control mechanism and switch for effective reset

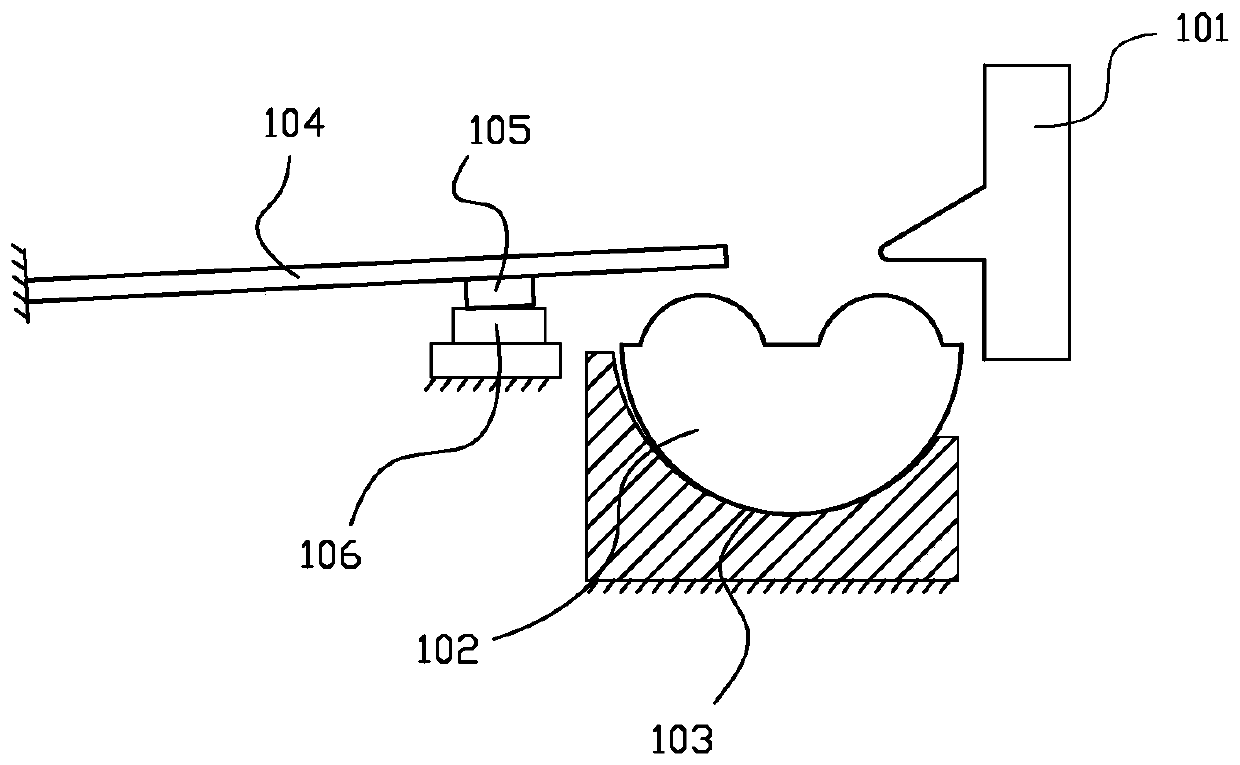

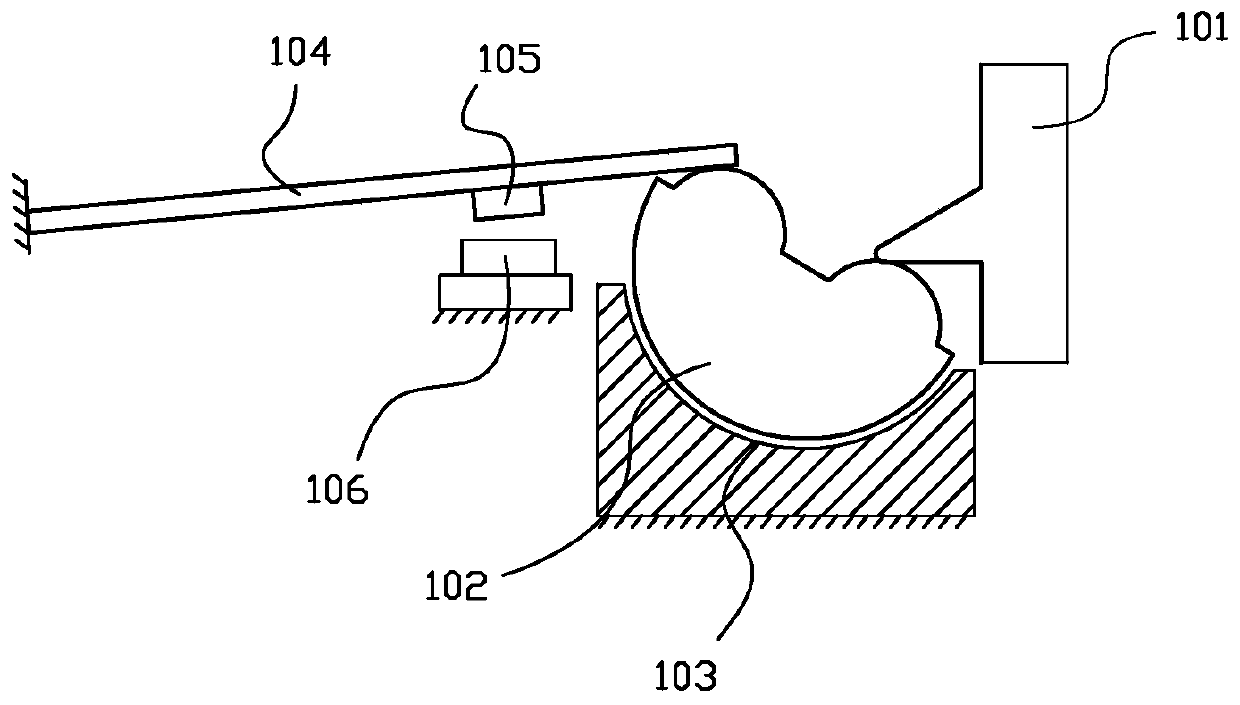

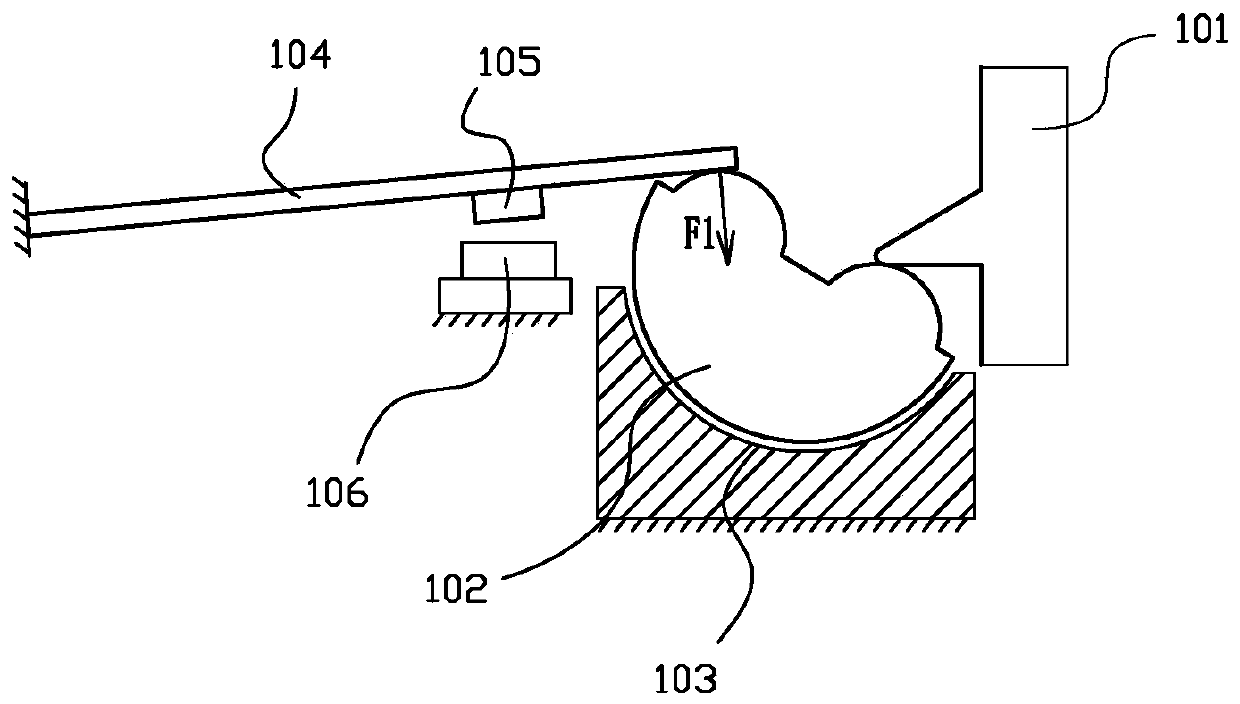

A contact control and switch technology, applied in contact drive mechanisms, contacts, electric switches, etc., can solve problems such as difficulty in rolling, failure to push sliding wheel 102 to reset, failure to automatically reset and close, etc., to ensure effective reset and avoid Effects that cannot be effectively reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The effective reset contact control mechanism of the present invention is suitable for switches, circuit breakers, side-mounted contacts and other electrical equipment provided with contact mechanisms and switchable on and off states. This embodiment is implemented in switches and acts on normal The moving reed of the closed contact is taken as an example for detailed description.

[0038] like Figure 5 to Figure 8 As shown, the effective reset contact control mechanism includes a sliding wheel 40, a sliding seat 31, and a sliding control part 21. The sliding seat 31 is provided with a sliding groove 32. The sliding wheel 40 includes a control end 41 and a driving end 42 at both ends. And the cambered surface 43 matched with the sliding groove 32 , the sliding wheel 40 is matched with the sliding groove 32 of the sliding seat 31 through the cambered surface 43 . The sliding control part 21 cooperates with the control end 41 of the sliding wheel 40, and the driving end...

Embodiment 2

[0056] This embodiment provides an effective reset switch based on the contact control mechanism, such as Figure 9 to Figure 11As shown, in this embodiment, two pairs of normally closed contacts and two pairs of normally open contacts are set, and two pairs of normally closed contacts and two pairs of normally open contacts are respectively symmetrically arranged on both sides of the contact control mechanism. The control mechanism controls the forced opening and auxiliary reset of the normally closed contacts. Specifically, it includes housing 30, spring 60, shrapnel 61, normally closed static spring 62, normally closed moving spring 63 (ie moving reed 50), normally closed moving contact 64 (ie moving contact 51), normally closed static contact Point 65 (i.e. static contact 52), normally open static spring 66, normally open moving spring 67, normally open moving contact 68, normally open static contact 69, bracket 70, contact control mechanism, sliding seat 31 and shell 30 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com