A kind of hemostatic material modified by silicate clay and preparation method thereof

A technology of hemostatic material and silicate, which is applied in medical formula, surgical adhesives, surgery, etc., can solve the problems of limited adhesion of hemostatic material, difficulty in follow-up treatment, and reduced hemostatic ability, so as to be beneficial to wound healing and reduce cost. Inexpensive, fast hemostasis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of halloysite nanotubes:

[0041] Weigh 5.0 g of raw halloysite that has been ground, washed and centrifuged, add 500 mL of deionized water and ultrasonically crush it at 1500 W for 2 hours to obtain halloysite nanorods with an average size below 1 μm.

[0042] (2) Preparation of halloysite-modified hemostatic material:

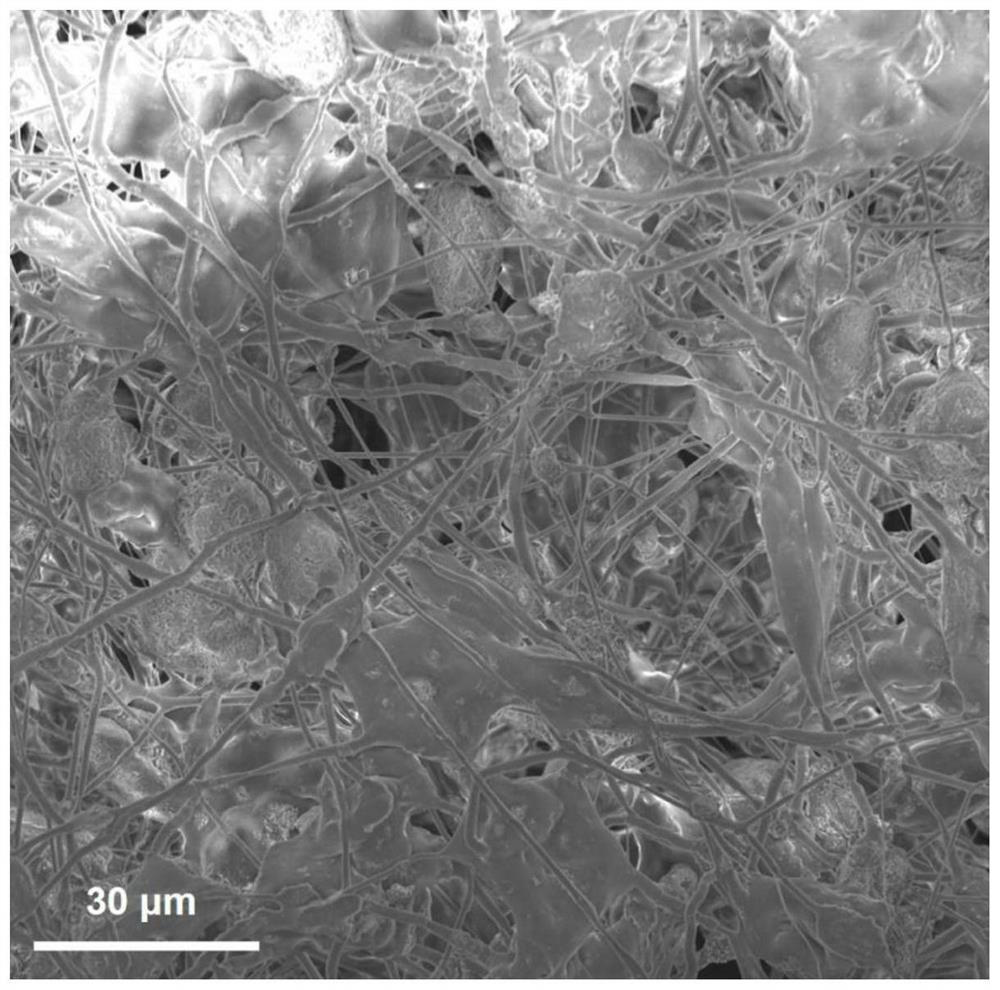

[0043] Dissolve 1.0 g of polyvinylpyrrolidone in 10 mL of absolute ethanol, add 1.50 g of halloysite nanorods, and stir in a water bath at room temperature for 36 hours; perform electrospinning and set the drum speed to 500 r / min, and the distance between the needle and the drum (receiving distance) is 21cm, the liquid flow rate is 0.05mL / min, the positive electrode voltage is 10kV, and the negative electrode voltage is 2kV, the haemostatic material modified by halloysite is prepared, and the SEM map is as followsfigure 1 Shown: Halloysite groups in the halloysite-modified hemostatic material are distributed in the 3D network structure ...

Embodiment 2

[0047] (1) Preparation of halloysite nanotubes:

[0048] Weigh 5.0 g of raw halloysite that has been ground, washed and centrifuged, add 500 mL of deionized water and ultrasonically crush it at 1500 W for 2 hours to obtain halloysite nanorods with an average size below 1 μm.

[0049] (2) Preparation of halloysite-modified hemostatic material:

[0050] Dissolve 1.0 g of polyvinylpyrrolidone in 10 mL of absolute ethanol, add 0.50 g of halloysite nanorods, and stir in a water bath at room temperature for 36 hours; perform electrospinning and set the drum speed to 500 r / min, the distance between the needle and the drum to 21 cm, and the liquid The speed is 0.05mL / min, the positive electrode voltage is 10kV, and the negative electrode voltage is 2kV to prepare halloysite-modified hemostatic material.

[0051] (3) Hemostasis experiment:

[0052] Rats were anesthetized by intraperitoneal injection of 10% chloral hydrate (0.3ml / 100g), fixed in the supine position, and disinfected. A...

Embodiment 3

[0054] (1) Preparation of attapulgite nanorods:

[0055] Weigh 5.0 g of raw ore attapulgite after grinding, washing and centrifugation, add 500 mL of deionized water and ultrasonically crush it at 1500 W for 2 hours to obtain attapulgite nanorods with an average length of less than 2 μm.

[0056] (2) Preparation of hemostatic material modified by attapulgite:

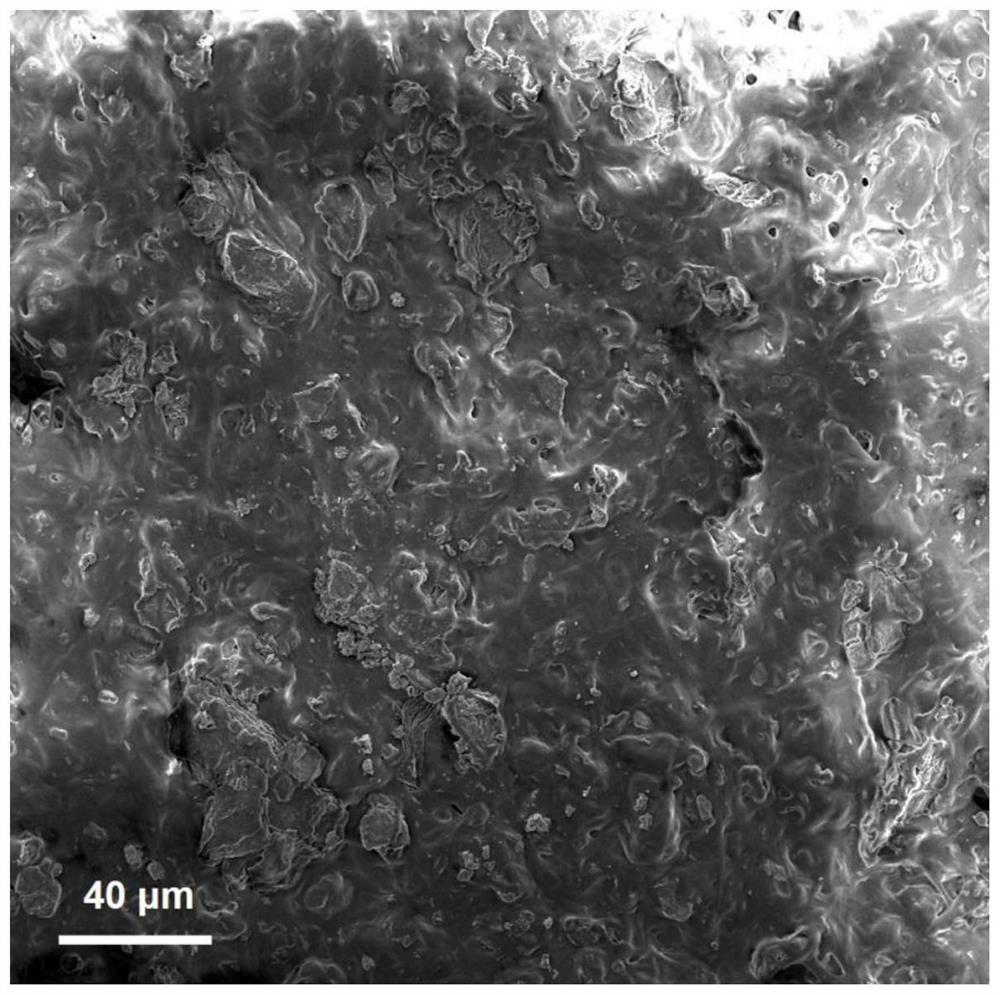

[0057] Dissolve 1.0 g of polyvinylpyrrolidone in 10 mL of absolute ethanol, add 1.50 g of attapulgite nanorods, and stir in a water bath at room temperature for 36 hours; perform electrospinning by setting the drum speed to 500 r / min, and the distance between the needle and the drum to 21 cm. The speed is 0.05mL / min, the positive voltage is 10kV, and the negative voltage is 2kV. The hemostatic material modified by attapulgite is obtained, and the SEM spectrum is as follows figure 2 As shown: the hemostatic material has a rough surface film structure, and the film is composed of attapulgite after partial rod crystal b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com