Automatic winding and arranging system for vehicle-mounted water hose

A hose, automatic technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of cumbersome operation process, low efficiency, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further described in conjunction with the following examples.

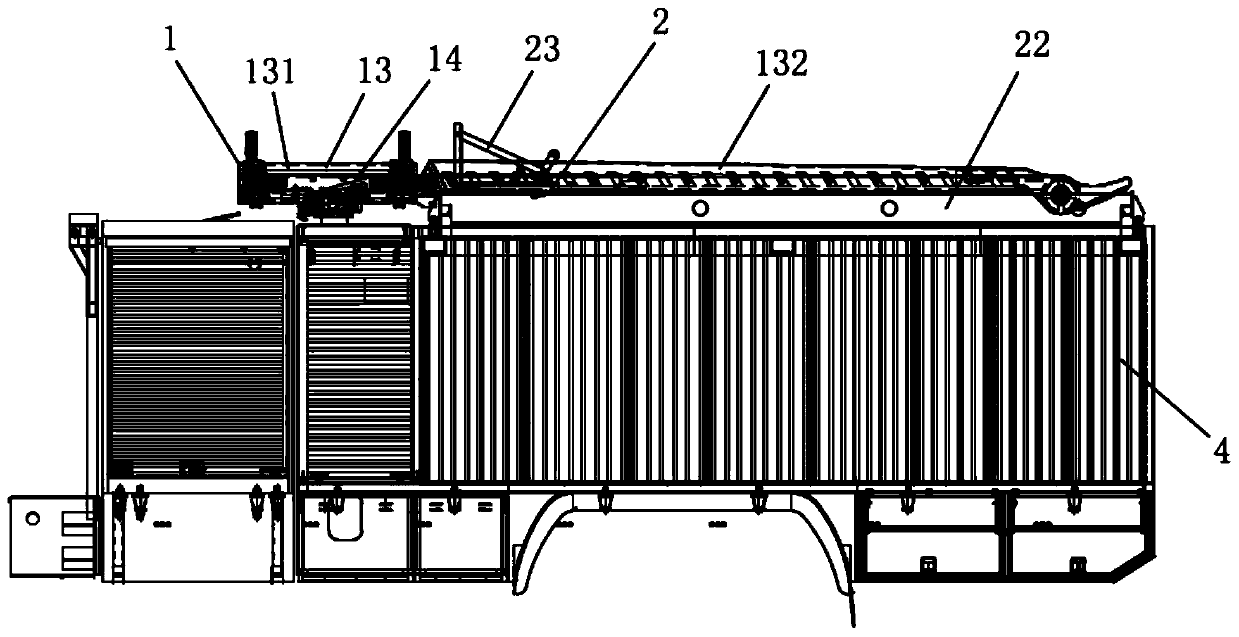

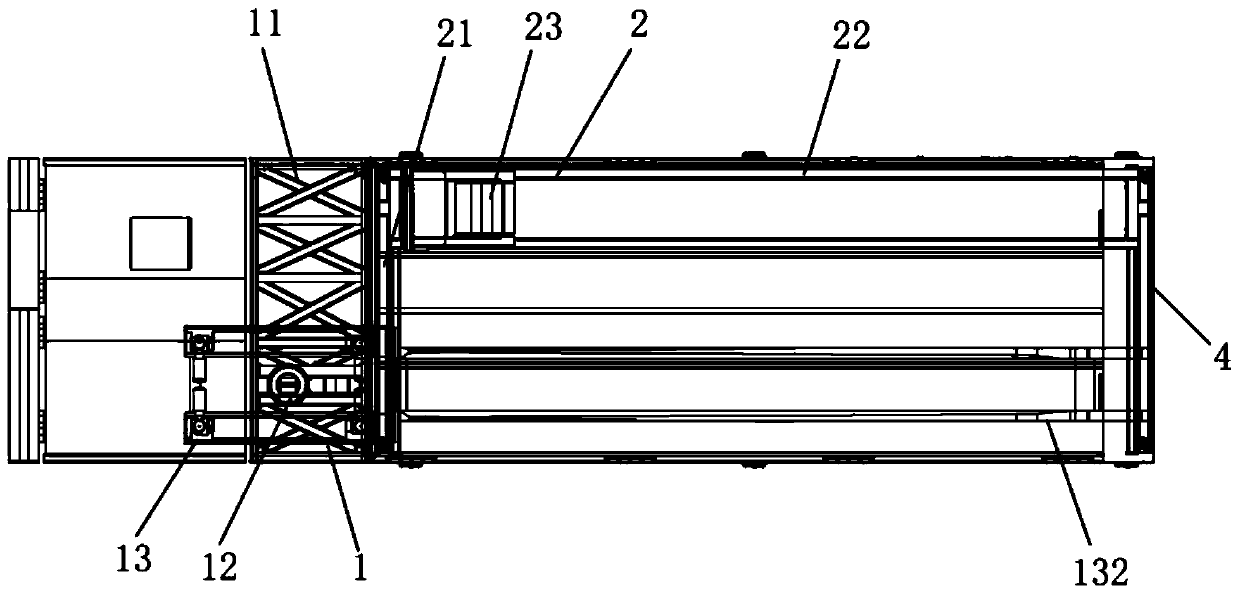

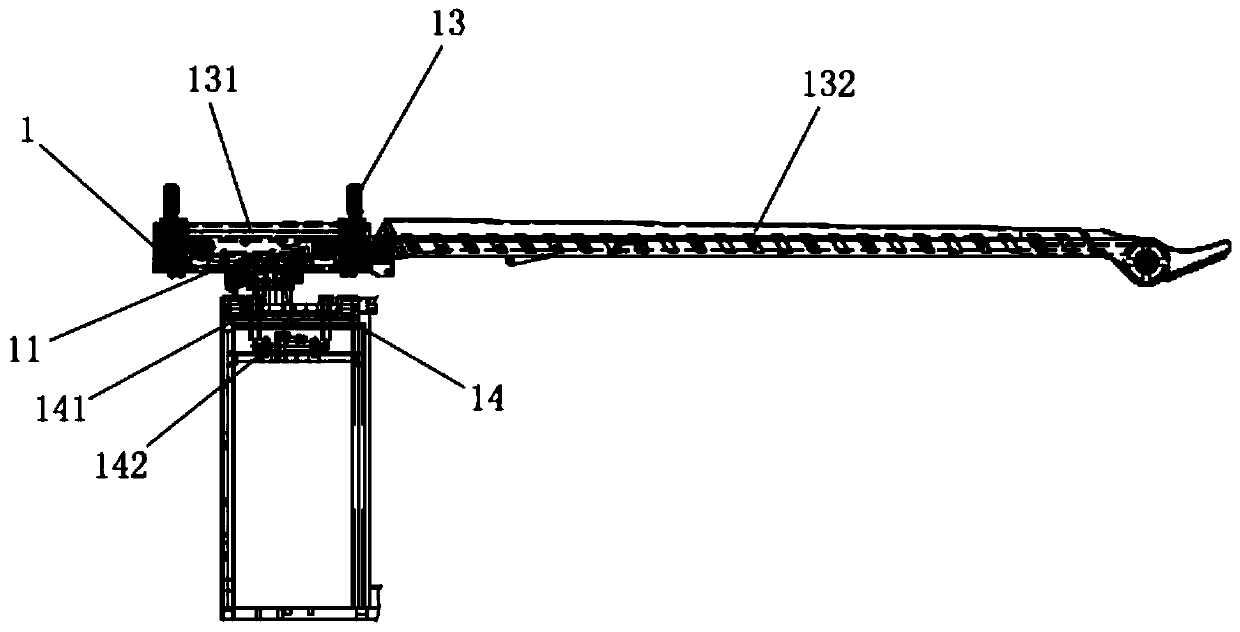

[0039] A kind of vehicle-mounted hose automatic winding and finishing system of this embodiment, such as figure 1 , figure 2 and Image 6As shown, it includes a hose winding mechanism 1 and a hose finishing mechanism 2, which are installed on the top of the fire truck compartment 40, wherein: the hose winding mechanism 1 includes a base 11, a mobile support 12 arranged on the base 11, The hose rewinding device 13 that is arranged on the mobile support 12 and can rotate relatively, and the first sprocket transmission mechanism 14 that can make the mobile support 12 translate on the base 11; The set slide rail 21, the moving longitudinal beam 22 arranged on the sliding rail 21, the belt management trolley 23 that can move back and forth on the moving longitudinal beam 22 to carry out longitudinal arrangement to the hose and the movable longitudinal beam 22 can be placed on the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com