Glass hollow slab imitating crystal crushed stones and manufacturing method thereof

A technology of crystal crushed stone and production method, which is applied to building components, buildings, building structures, etc., can solve the problems of poor three-dimensional layering of patterns, overall weight, inconvenient use and handling, and achieve good three-dimensional layering and overall weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

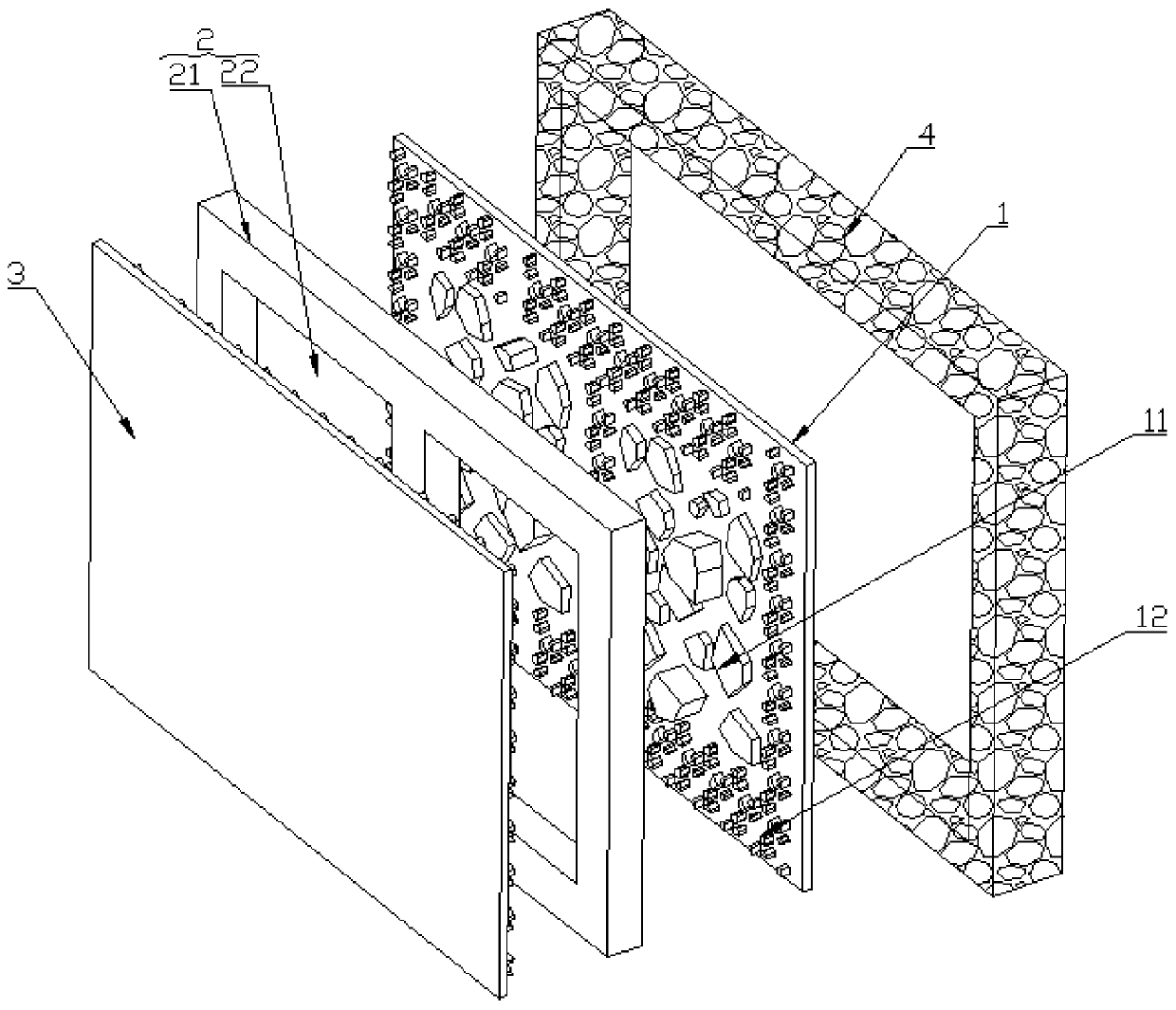

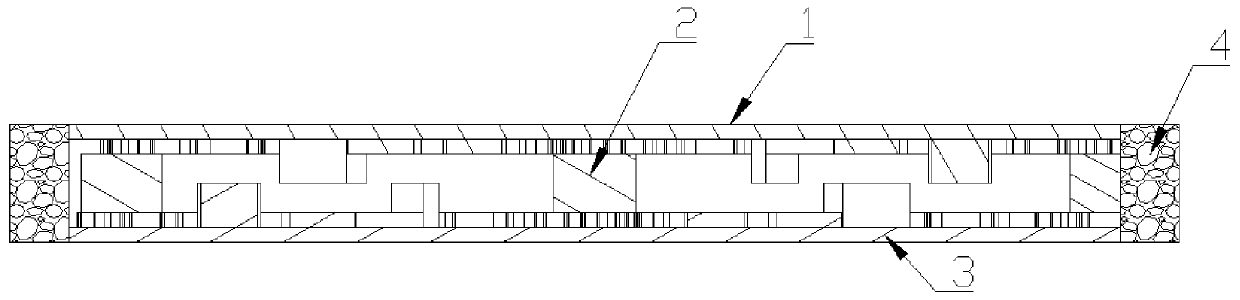

[0028] Such as figure 1 , figure 2 As shown, a glass hollow plate imitating crystal gravel provided in this embodiment includes a broken glass surface plate 1 and a light reinforcement frame 2; Two lightening through-holes 22 are formed between several ribs 21; a uniform crumb layer 12 matching the position of the cullet 21 is provided on one side of the cullet surface plate 12, and the uniform crumb layer 12 adopts a broken glass with a diameter of about 2mm. Glass granules, one side of the cullet surface layer plate 1 is provided with an irregular granule layer 11 matching the position of the lightening through hole 22, and the irregular granule layer 11 adopts glass granules with a particle diameter greater than 2 mm and uneven thickness. The grain layer 12 is adhered to one side of the rib 21 , and the irregular grain layer 11 is located in the lightening through hole 22 . The uniform crumb layer 12 makes the thickness of this place relatively uniform, so that when it i...

Embodiment 2

[0034] Such as figure 1 , figure 2As shown, a glass hollow plate imitating crystal gravel provided in this embodiment includes a broken glass surface plate 1 and a light reinforcement frame 2; Two lightening through-holes 22 are formed between several ribs 21; a uniform crumb layer 12 matching the position of the cullet 21 is provided on one side of the cullet surface plate 12, and the uniform crumb layer 12 adopts a broken glass with a diameter of about 2mm. Glass granules, one side of the cullet surface layer plate 1 is provided with an irregular granule layer 11 matching the position of the lightening through hole 22, and the irregular granule layer 11 adopts glass granules with a particle diameter greater than 2 mm and uneven thickness. The grain layer 12 is adhered to one side of the rib 21 , and the irregular grain layer 11 is located in the lightening through hole 22 . The uniform crumb layer 12 makes the thickness of this place relatively uniform, so that when it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com