Binding trolley for concrete steel bars and binding construction method

A technology for tying concrete steel bars and steel bars, which is used in binding trolleys, binding trolleys for concrete steel bars, and binding construction fields. Give a good solution to problems such as easy construction and operation, improve anti-overturning ability, and improve operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

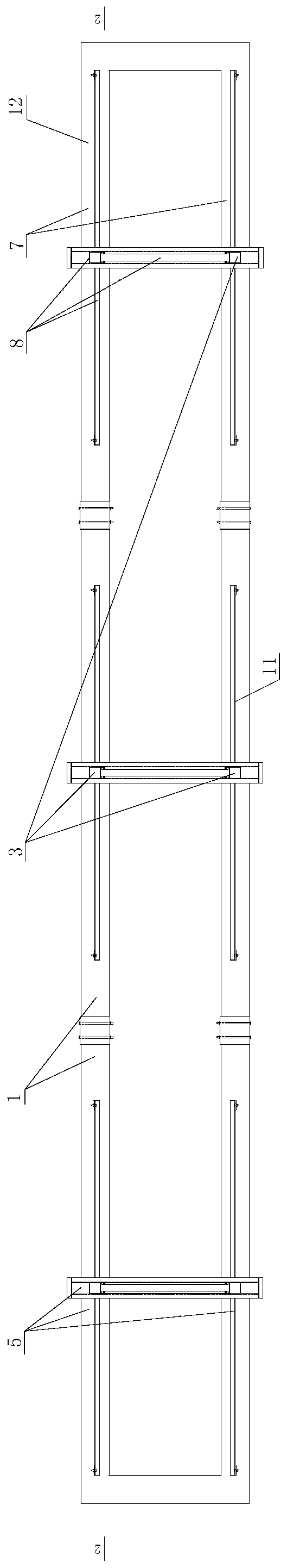

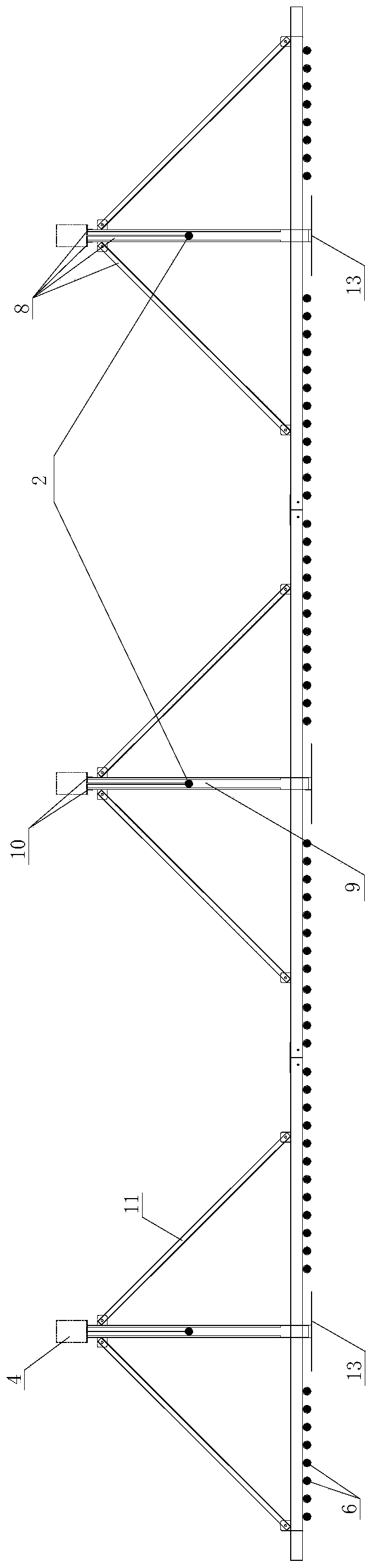

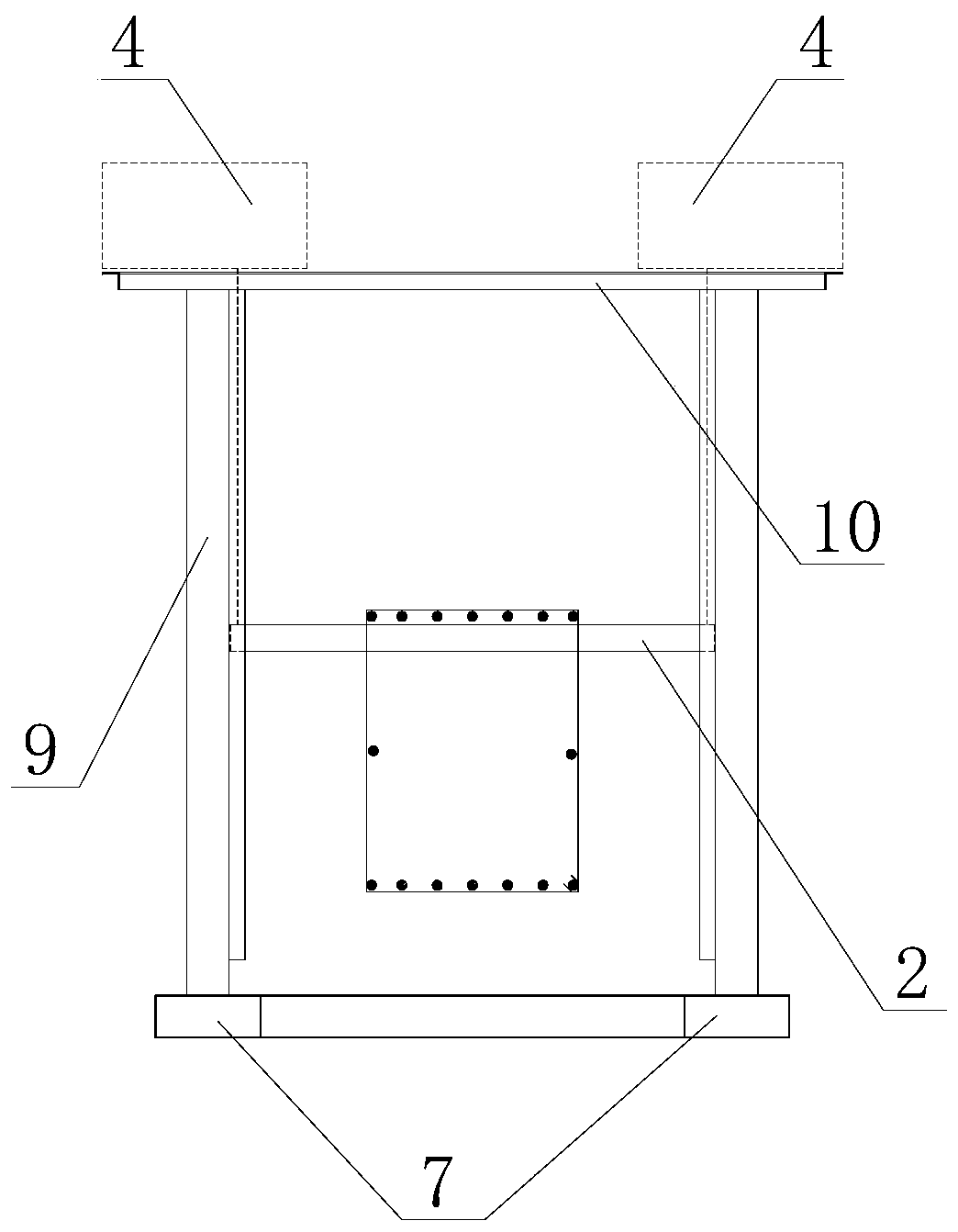

[0043] The binding trolley provided by this application mainly consists of 13 parts.

[0044] ①: Base, welded by Q345, 300×120×2.5mm rectangular tube;

[0045] ②: Column, made of Q345, 120×120×3mm square tube;

[0046] ③: Connecting angle steel, Q345, ∠50×50×5mm;

[0047] ④: Hoist, straight, rated lifting capacity 3.5t hoist, equipped with automatic locking device;

[0048] ⑤: Steel wire rope, Q345, φ14mm;

[0049] ⑥: Bearing steel bar, Q345, φ75mm;

[0050] ⑦: Steel skeleton;

[0051] ⑧: Angle steel brace, Q345, ∠50×50×5mm;

[0052] ⑨: Connecting channel steel, Q345, section 300×120×5mm, length 300mm;

[0053] Connecting bolts, Q345, φ16mm;

[0054] Roller, φ80mm, length 260mm;

[0055] Hydraulic outriggers, rated lifting capacity 4t;

[0056] Head steel plate, Q345, 2.5mm thick.

[0057] The raw materials and components of the 13 components are easy to obtain and low in cost, and the whole structure is easy to manufacture, reliable in performance, convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com