Equipment and method for hole completion of long distance screen pipe by directional drilling for underground gas extraction in coal mine

A technology of gas drainage and directional drilling, which is applied in the direction of gas discharge, mining equipment, mining fluid, etc. It can solve the problems of difficulty in lowering long-distance screens, easy blockage of screen holes, and easy blockage, so as to improve gas pumping. mining effect, long drop-down distance, and high drop-down efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

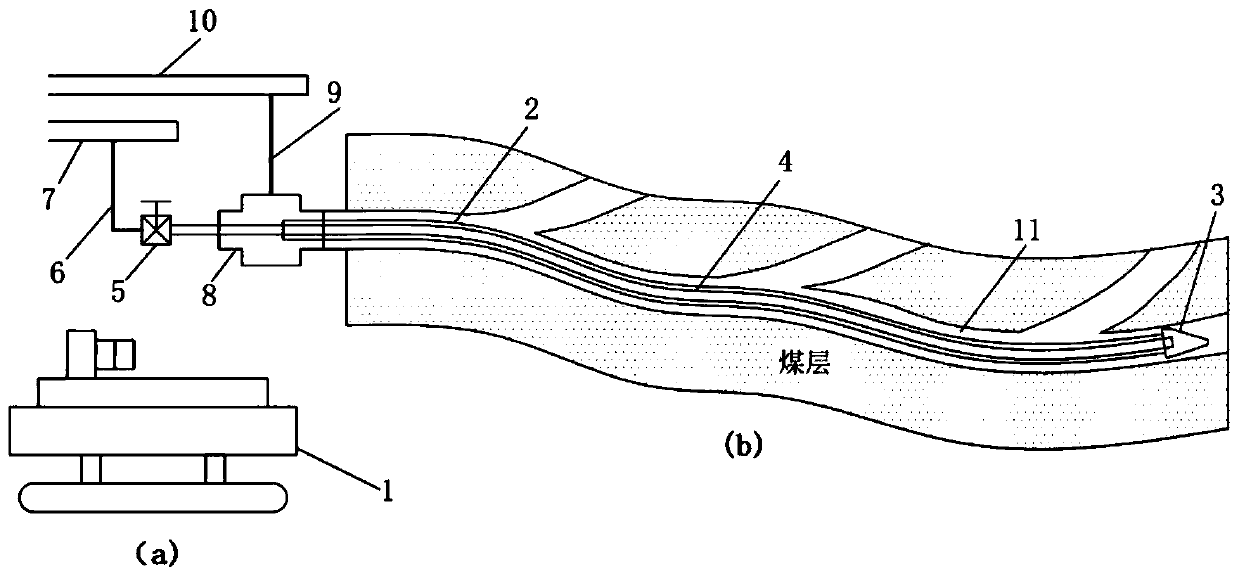

[0042] see figure 1 , a kind of directional drilling and long-distance screen pipe completion equipment for underground gas drainage in coal mines, including a directional drilling rig 1 with the function of lowering the pipeline, a slotted screen pipe 2, an eccentric guide device 3, an air pipe 4, and a first stop valve 5 , pressure air hose 6, mine air supply pipeline 7, sealing continuous pumping device 8, drainage hose 9, mine gas drainage pipeline 10, etc., wherein:

[0043]The directional drilling rig 1 with the pipeline lowering function is used for the construction of the directional drilling 11 for gas drainage, and the lowering of the slotted screen pipe 2 and the air pipe 4 .

[0044] The slotted screen pipe 2 is connected with the eccentric guide device 3 and lowered into the directional borehole 11 to ensure a smooth gas drainage channel. It is made of PVC material, the inner wall and outer wall are flat, the two ends are connected by threads, and there are recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com