A three-cavity profiling suction muffler and compressor

A muffler and cylinder block technology, which is applied to machines/engines, mechanical equipment, liquid variable volume machinery, etc., can solve the problems of poor noise reduction effect, easy resonance, and insufficient noise reduction for medium and low frequency noise, and achieves an increase in the Noise reduction, vibration and noise avoidance, simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

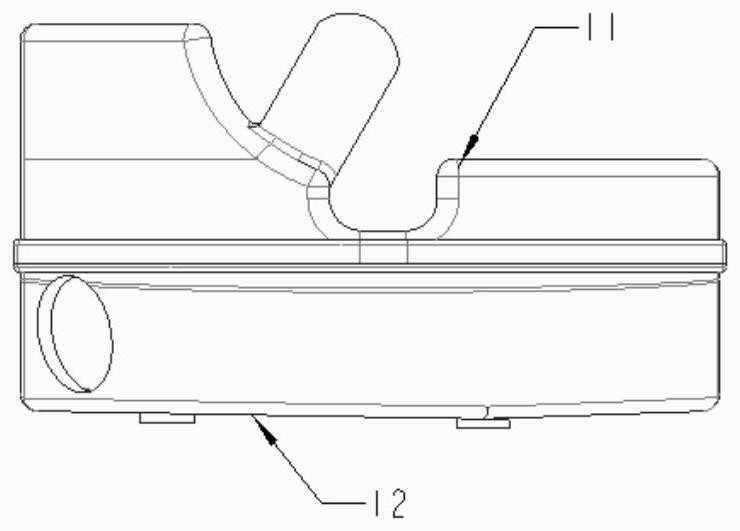

[0042] Attached below Figure 3-7 The present invention is described in detail, specifically, the structure is as follows:

[0043] In this embodiment, a three-chamber profiling suction muffler includes a first housing 11 and a second housing 12, the first housing 11 is installed above the second housing 12, and the first housing 11 and the second housing 12 The contacting side of the second housing 12 is an open structure, and slots are provided at the open ends of the two, and the front and back are inserted together through the slot structure to form a closed structure, which has good sealing performance and high structural strength.

[0044] The interior of the three-chamber profiling suction muffler is divided into a first expansion cavity 14, a second expansion cavity 15 and a resonance cavity 16, and the first expansion cavity 14 is connected in series with the second expansion cavity 15, and the second expansion cavity 15 and the resonance cavity 16 in series. The st...

Embodiment 2

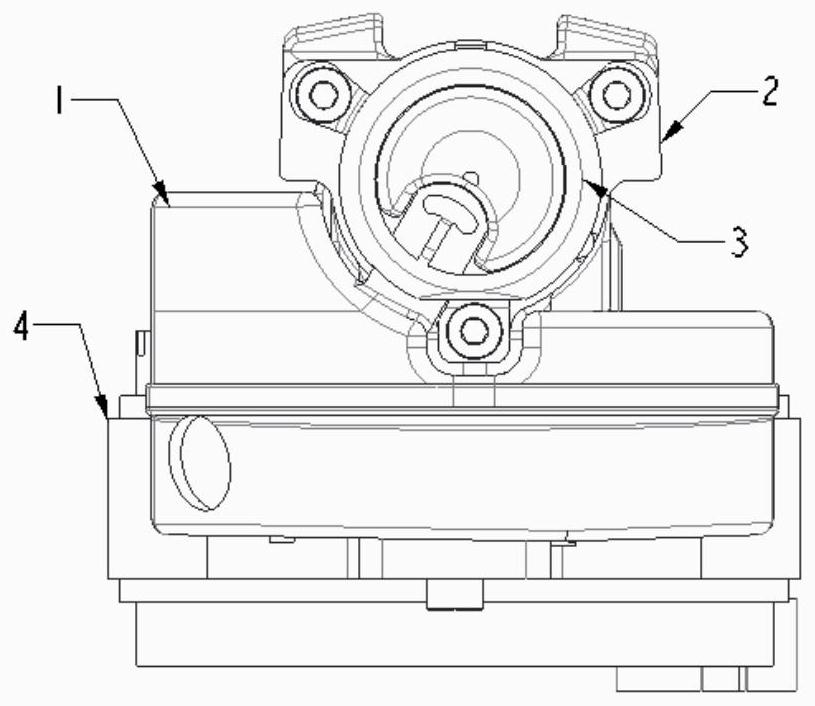

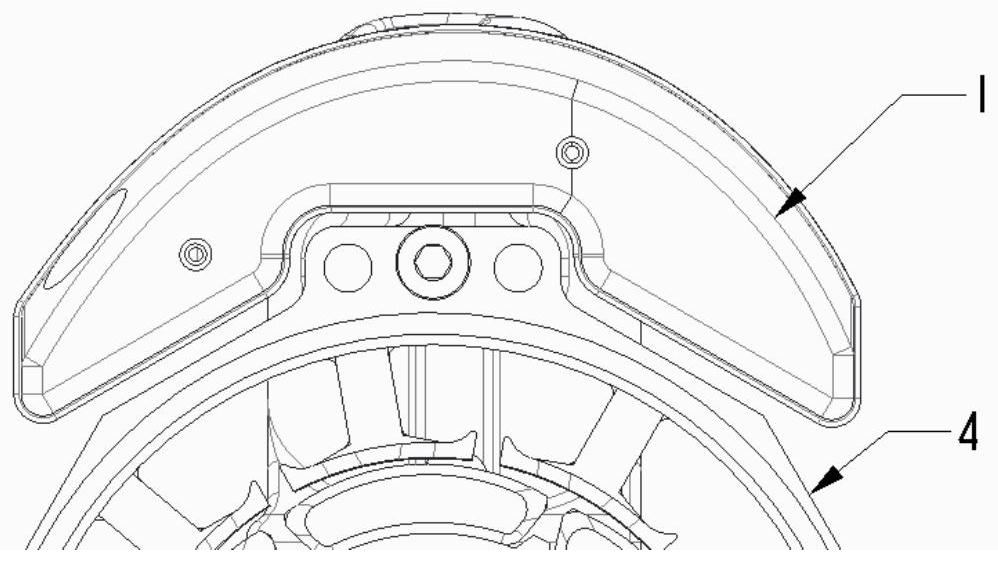

[0066] Such as figure 1 and figure 2 As shown, a compressor includes a suction muffler 1, a cylinder block 2, and a motor 4. The suction muffler 1 adopts the three-chamber profiling suction muffler of the first embodiment.

[0067] The cylinder block 2 is installed on the top of the suction muffler 1, and the air outlet connecting section 115 is matched with the cylinder head 3; The two surfaces match.

[0068] The shape of the suction muffler 1 is consistent with the cylinder block 2, the cylinder head 3, and the motor 4, that is, it adopts a profiling design, which can make full use of the space and increase the volume of the muffler.

[0069] The suction muffler 1 maintains a safe distance of 1-2mm from the cylinder block 2, the cylinder head 3, and the motor 4, so as to avoid contact and collision.

[0070] Preferably, the safety distance is set to 2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com