Automatic cleaning and smoke discharging device

An automatic cleaning and equipment technology, applied in lighting and heating equipment, oil fume removal, cleaning methods and utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

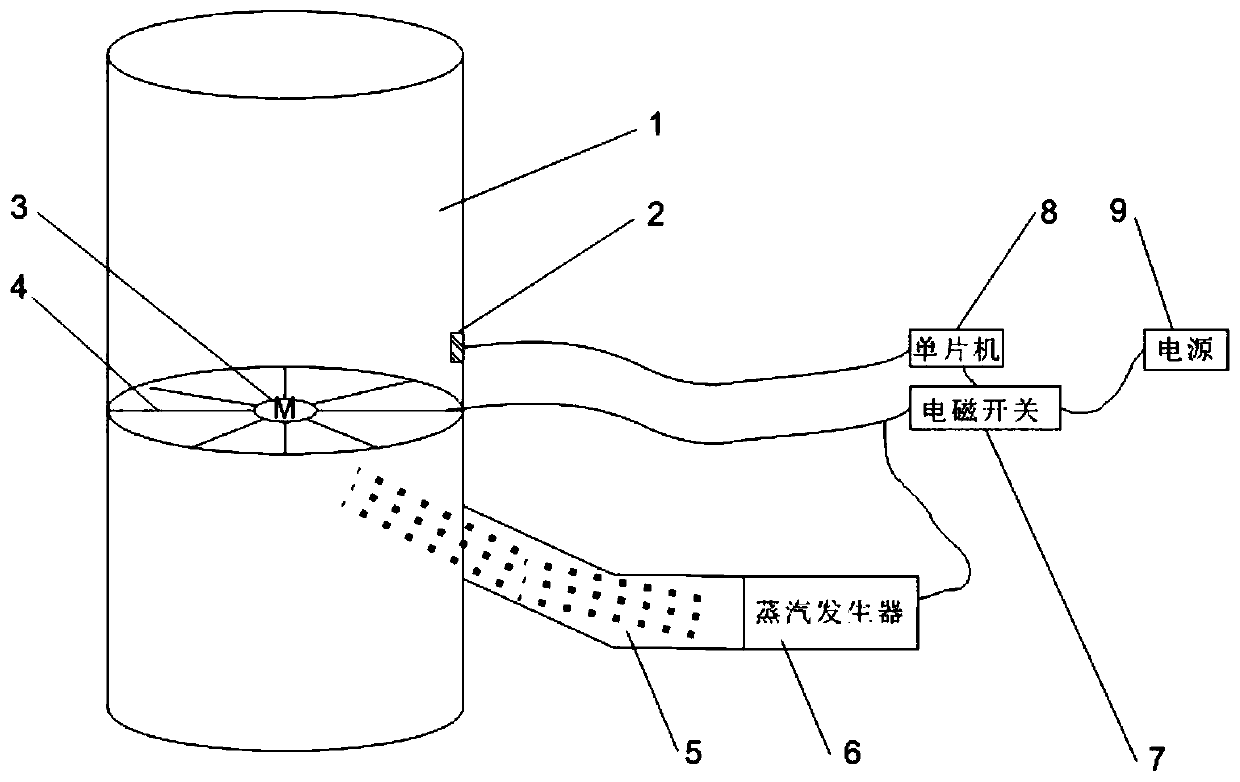

[0015] Such as figure 1 As shown, an automatic cleaning and exhausting equipment includes a smoke exhaust pipe 1 and a fan motor 3 and fan blades 4 in the pipe. The lower part of the smoke exhaust pipe 1 is the oil fume inlet, and the upper part is the oil fume outlet. Pipeline 5, oil fume concentration detection probe 2, the steam pipe 5 is installed at the position below the fan blade 4 in the exhaust pipe 1 and communicated with the output port of the steam generator 6, the oil smoke concentration detection probe 2 is arranged in the smoke exhaust pipe 1 The position above the fan blade 4 inside, the oil-salt concentration detection probe 2 is connected with the single-chip microcomputer module 8 outside the exhaust pipe 1 through a line, and the single-chip microcomputer module 9 judges whether there is oil fume according to the signal received, if it is judged that there is oil fume, then the output signal is given to The electromagnetic switch 7 makes it close and energi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com