Double-row microchannel header pipe and using method thereof

A technology of micro-channels and headers, which is applied in the direction of tubular elements, fixed conduit components, lighting and heating equipment, etc., can solve the problems of large refrigerant charge, poor distribution effect, and difficult design, so as to improve heat transfer performance, The effect of reducing resistance and increasing effective channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

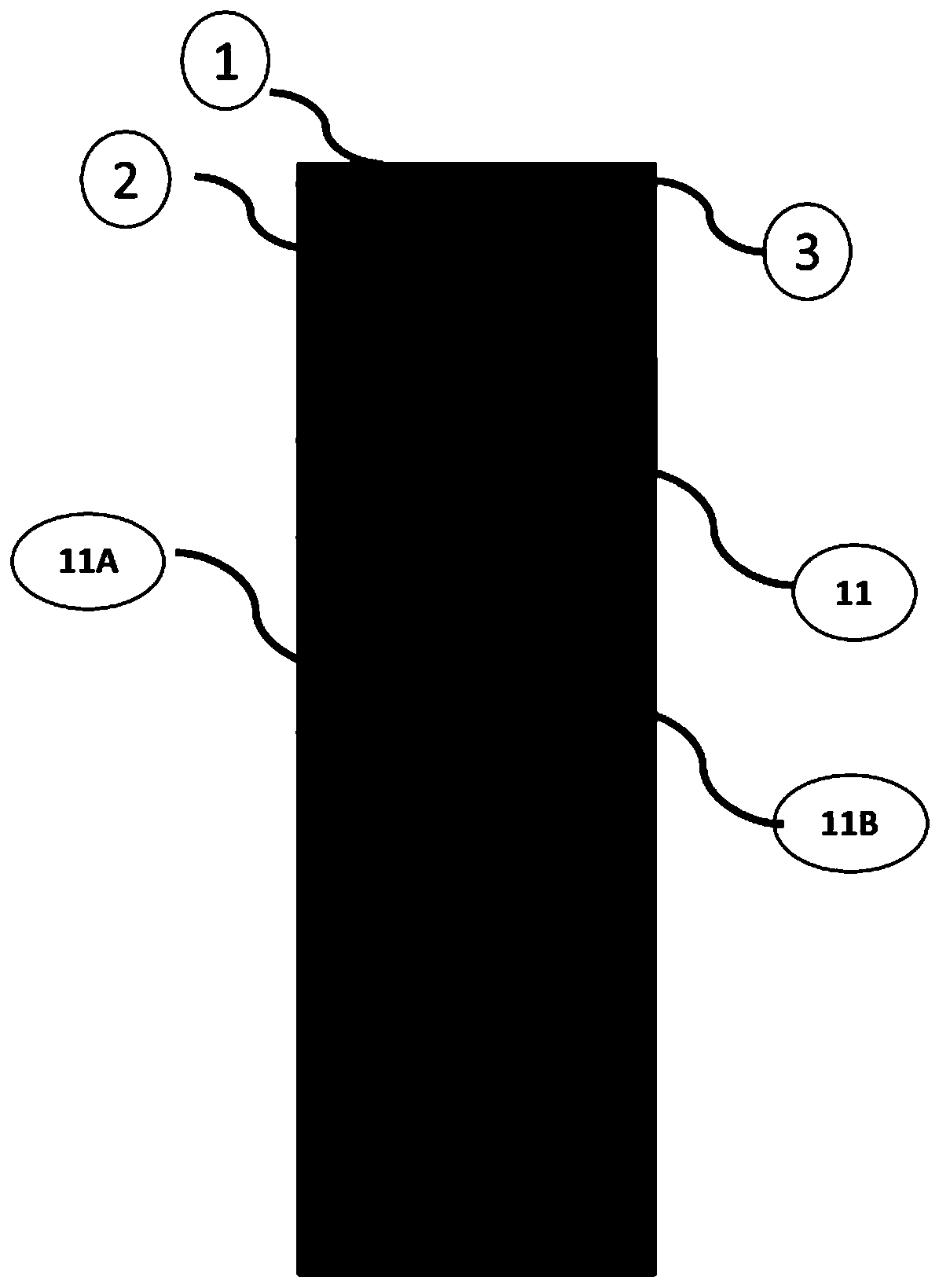

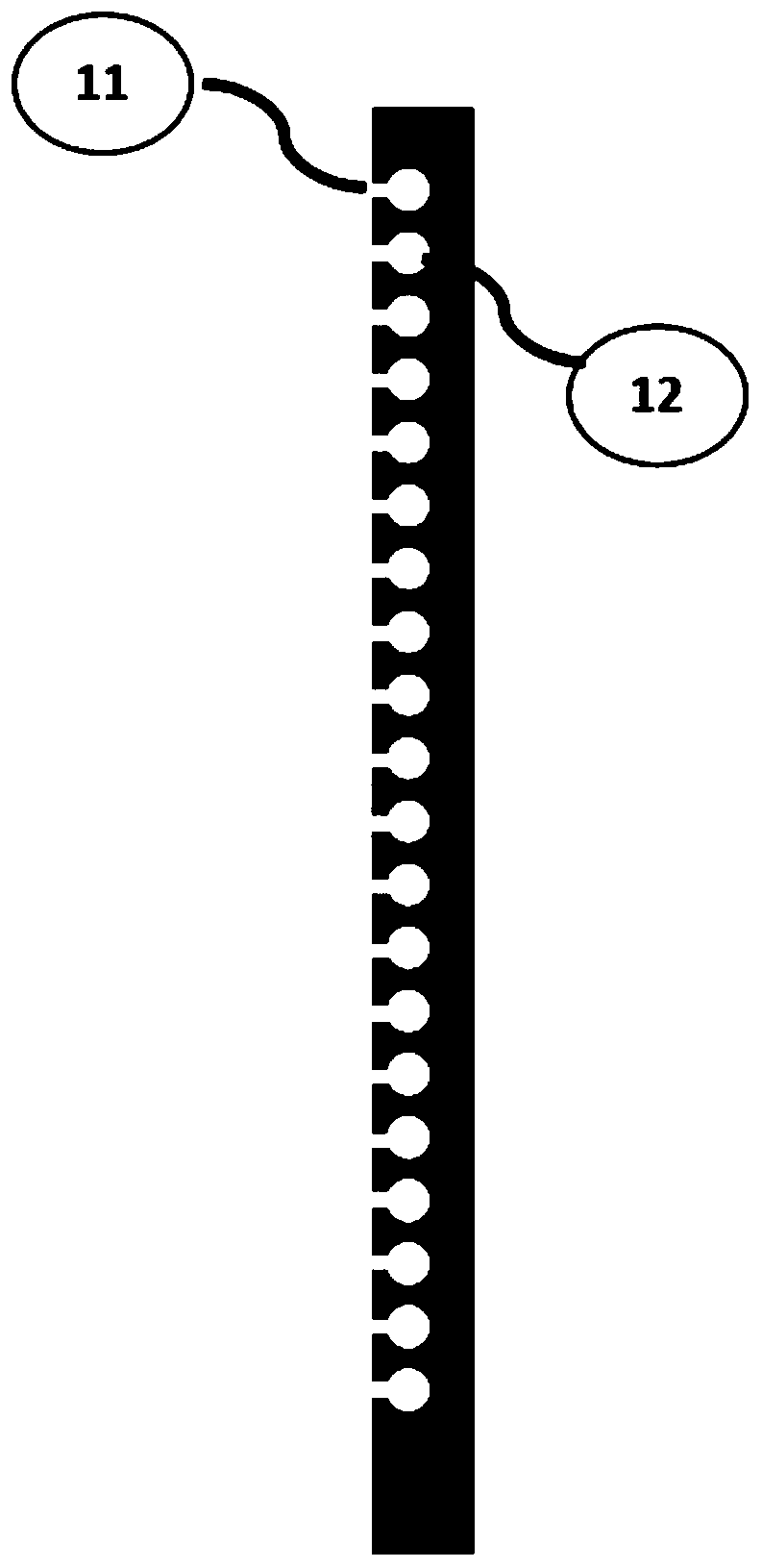

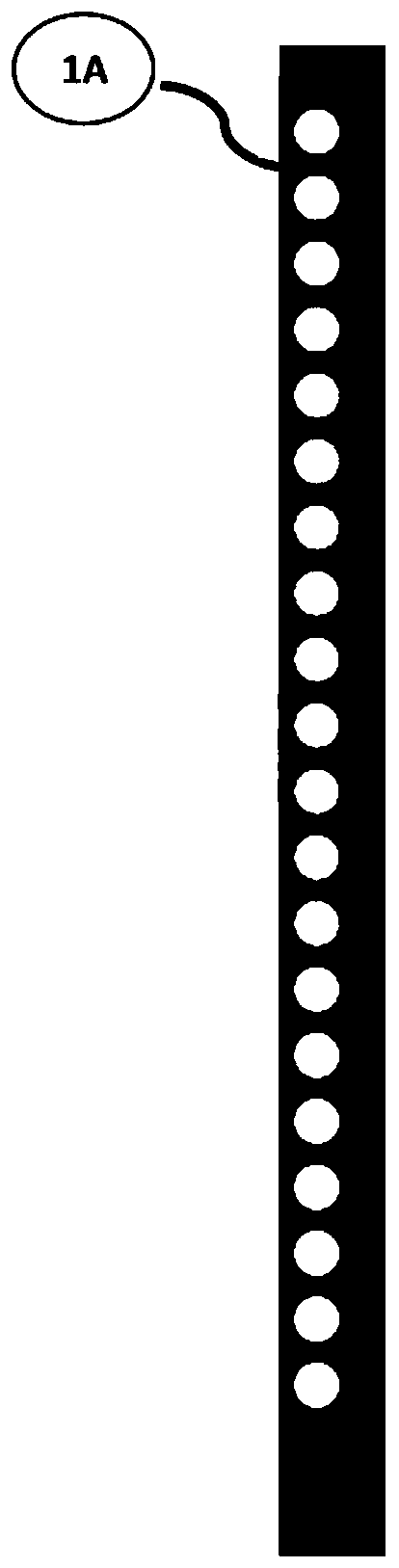

[0022] Such as figure 1 As shown, a double-row microchannel header of the present invention includes a core part 1, and a first side plate 2 and a second side plate 3 respectively fixed on both sides of the core part 1; the core part 1 For flat tube interfaces and flat tube channels evenly distributed on the top, the cross-sectional area of the flat tube channels 12 is 1.25 to 3.75 times the cross-sectional area of the flat tube interface 11, preferably 2 times in this embodiment. The cross-section of the flat tube channel is circular or rectangular, and if rectangular is used, rectangular is preferred.

[0023] Such as figure 1 with figure 2 As shown, the flat tube interface 11: includes a front flat tube interface 11A and a rear flat tube interface 11B, which are respectively used to connect the front flat tube and the rear flat tube; flat tube channel 12: used for communicating the front flat tube and the rear flat tube. The distance between the ends of the front fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com