Multi-channel corrosion-prevention rubber plate detection device and application method thereof

A detection device and multi-channel technology, which is applied in the direction of optical testing for flaws/defects, can solve problems such as complex structure, high cost, and low detection efficiency, and achieve the effect of simple device structure, low cost, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

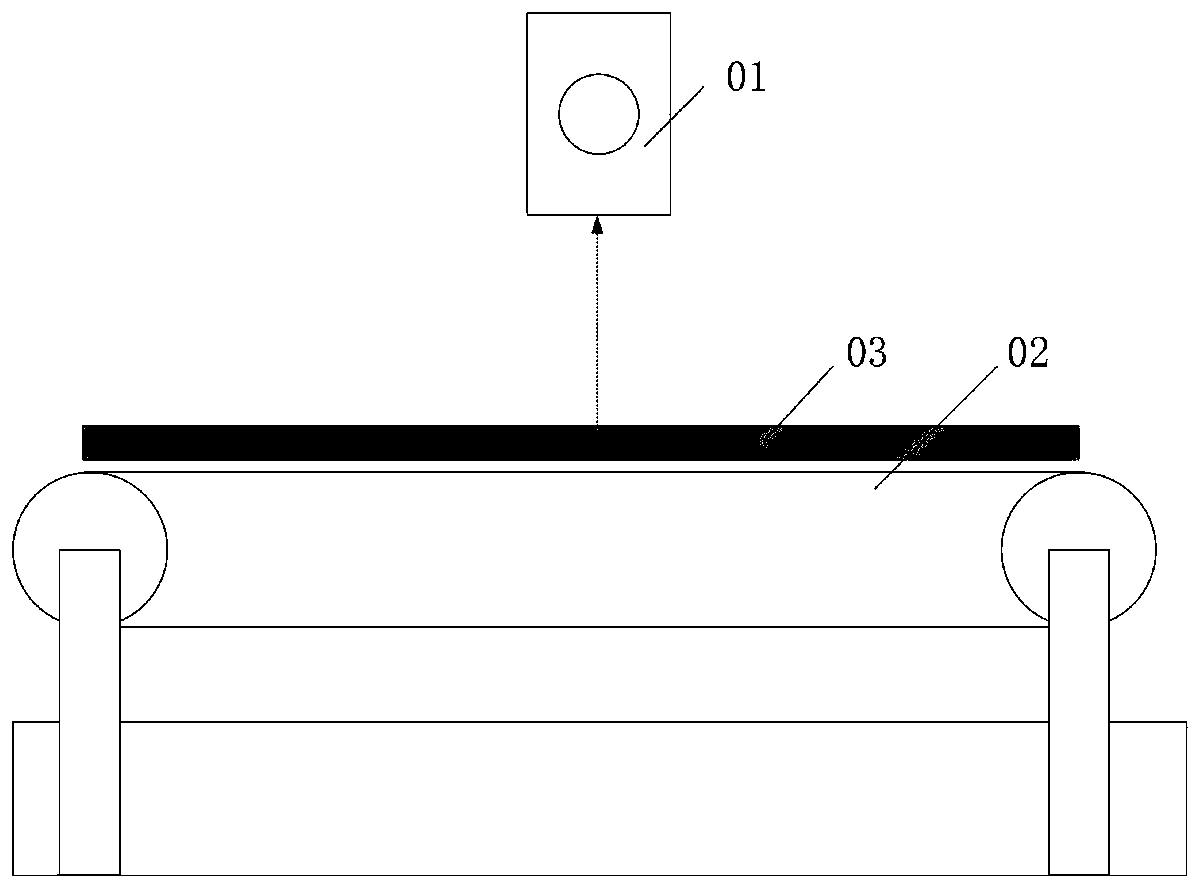

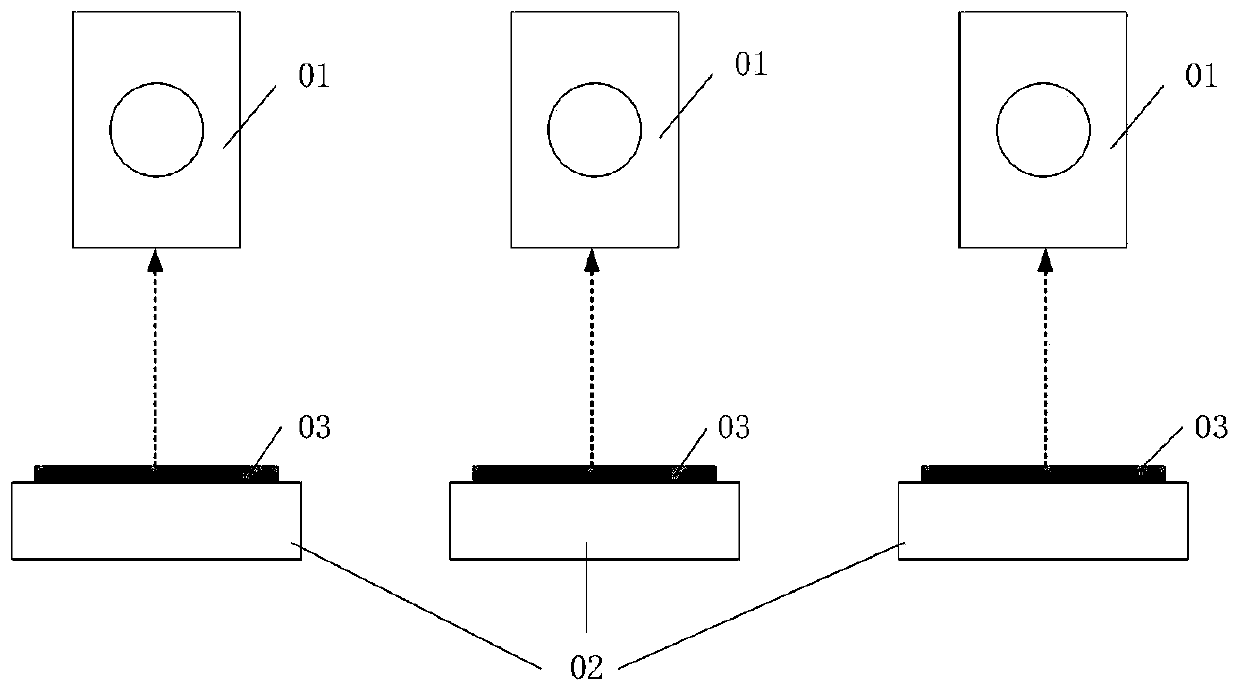

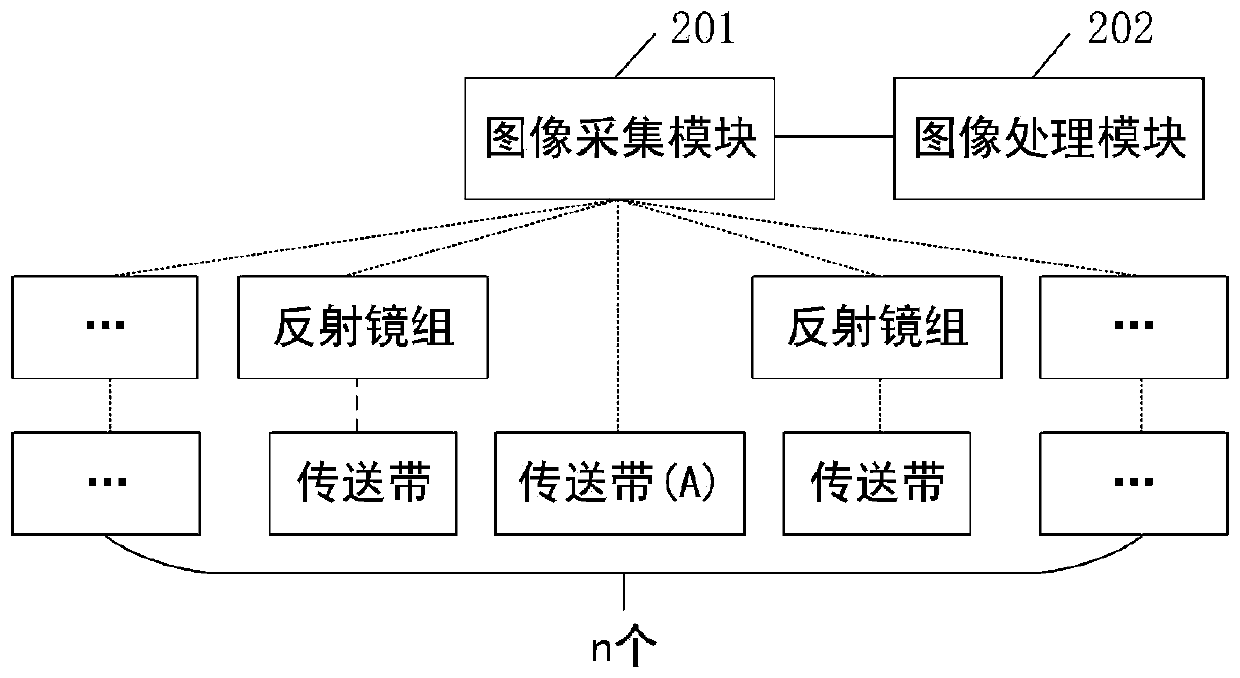

[0053] The embodiment of the present invention provides a multi-channel anti-corrosion rubber sheet detection device, which can simultaneously detect whether the quality of anti-corrosion rubber sheets on multiple production lines is qualified. Such as image 3 with Figure 4 As shown, when the total number of production lines is n (n ≥ 1), the corresponding number of conveyor belts is n, then the detection device includes an image acquisition module 201 and n-1 mirror groups, and the image acquisition module 201 can specifically It is CMOS industrial camera or CIS sensor. The image acquisition module 201 can be arranged directly above any conveyor belt A, and the lens faces the conveyor belt A, so that the image of the anti-corrosion rubber sheet on the conveyor belt A can be directly collected by the image acquisition module 201; the n-1 The mirror groups are respectively set corresponding to the remaining n-1 conveyor belts (all other conveyor belts except conveyor belt A...

Embodiment 2

[0076] On the basis of the above-mentioned embodiment 1, the embodiment of the present invention also provides another multi-channel anti-corrosion rubber sheet detection device, such as Figure 9 shown. The difference from Example 1 is that in Example 1, the image acquisition module 201 is set directly above a certain conveyor belt A, which can directly collect the image of the anti-corrosion rubber sheet on the conveyor belt A, so there is no need to set a reflector corresponding to the conveyor belt A. Mirror group, that is, a total of n-1 mirror groups are set; in embodiment 2, the image acquisition module 201 is arranged above the gap between any two conveyor belts, and the lens is facing downward, then a mirror needs to be set corresponding to each conveyor belt groups, that is, a total of n reflector groups are set. The setting method of Embodiment 1 can save the use of a set of mirror groups.

[0077] Likewise, in the embodiment of the present invention, each reflect...

Embodiment 3

[0085] The embodiment of the present invention combines the multi-channel anti-corrosion rubber sheet detection device described in embodiment 1 or embodiment 2 with the grinding device to provide an anti-corrosion rubber sheet grinding system with adjustable grinding gap, which can be used for uneven thickness The anti-corrosion rubber sheet realizes normal grinding.

[0086] Such as Figure 13 As shown, when the total number of production lines is n (n≥1), and the corresponding number of conveyor belts 3 is n, the grinding system provided by the embodiment of the present invention includes n grinding devices 1 and one detection device 2 . Wherein, the n grinding devices 1 are set corresponding to the n conveyor belts 3, so that the anti-corrosion rubber sheet is polished and then transmitted to the corresponding conveyor belt 3; the detection device 2 is the detection device described in embodiment 1 or embodiment 2 , which is used here to detect whether the anti-corrosion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com