Intelligent battery pairing repair method and system

A smart battery and repair method technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of damaging waterproof sealing, complicated operation, complicated production process, etc., to reduce the use of wires, reduce the volume of equipment, and practical operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

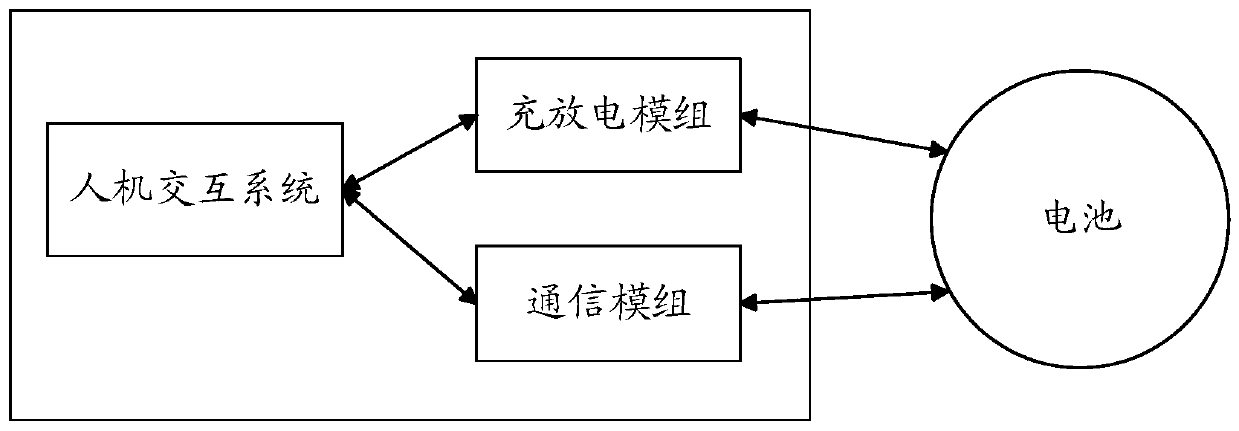

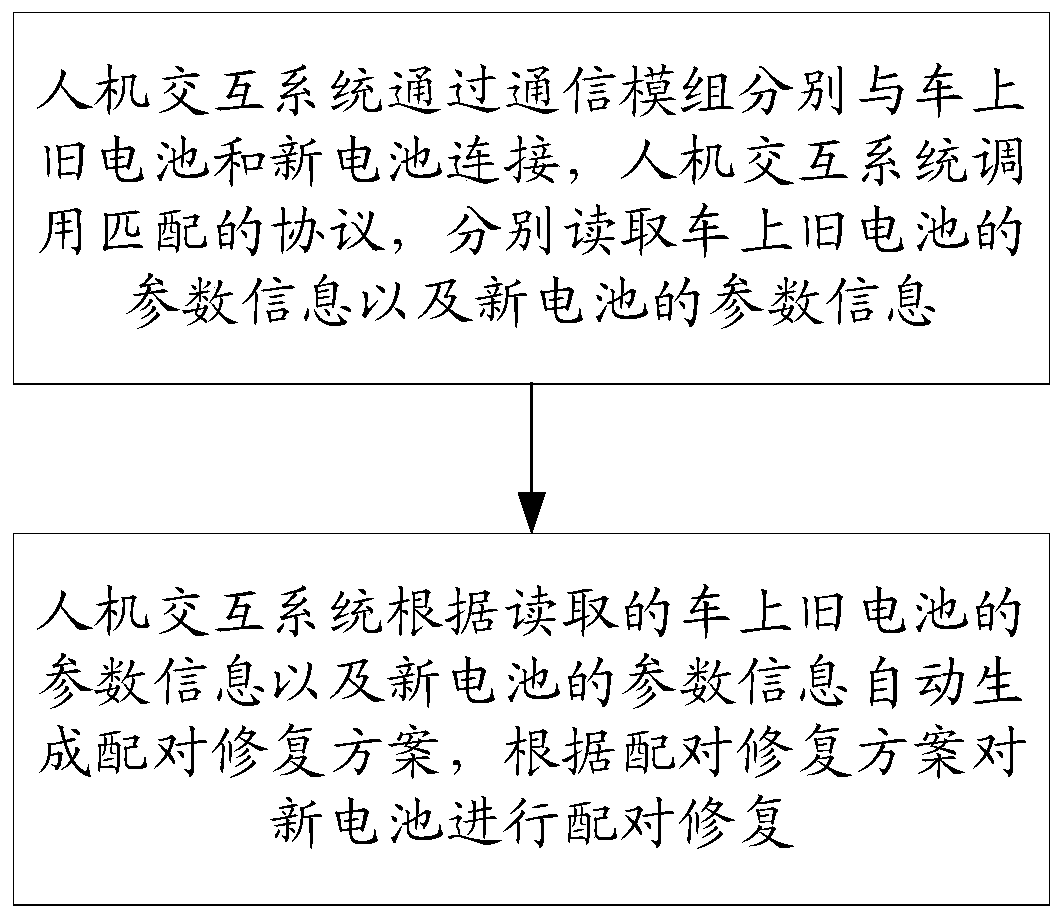

[0061] see Figure 1 to Figure 2 As shown, a preferred embodiment of an intelligent battery pairing repair method of the present invention, the present invention needs to provide a human-computer interaction system, a charging and discharging module and a communication module when the present invention is implemented; the charging and discharging module and the The communication modules are all connected in communication with the human-computer interaction system, and the charging and discharging modules and the communication modules are all connected with the battery (in the present invention, the battery includes old batteries and new batteries on the vehicle).

[0062] Among them, the communication module has CAN, 232, 485, I2C, SPI, TTL, Ethernet, WIFI, Bluetooth, ZigBee and other communication interfaces, which can realize communication with various batteries, and can also communicate with human-computer interaction systems Communication; the charging and discharging modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com