Outdoor inverter unit capable of realizing multi-machine parallel connection

An inverter and exterior technology, applied in the field of outdoor inverter units, can solve the problems of high processing cost and transportation cost of 2.5MW container, disadvantageous overall cost and high cost of the inverter, and achieve superior performance and dustproof. Good effect, the effect of reducing the amount of copper bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

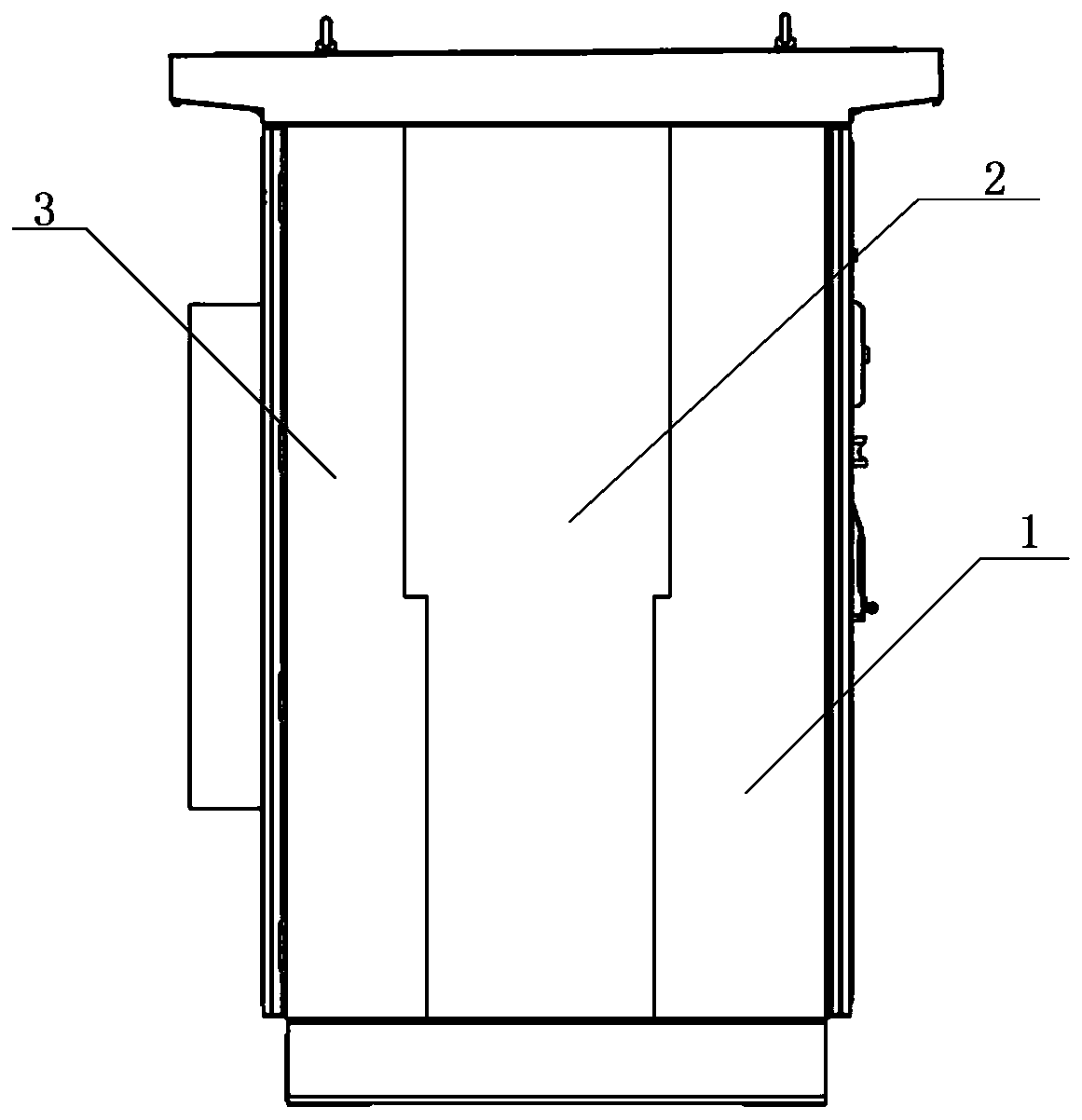

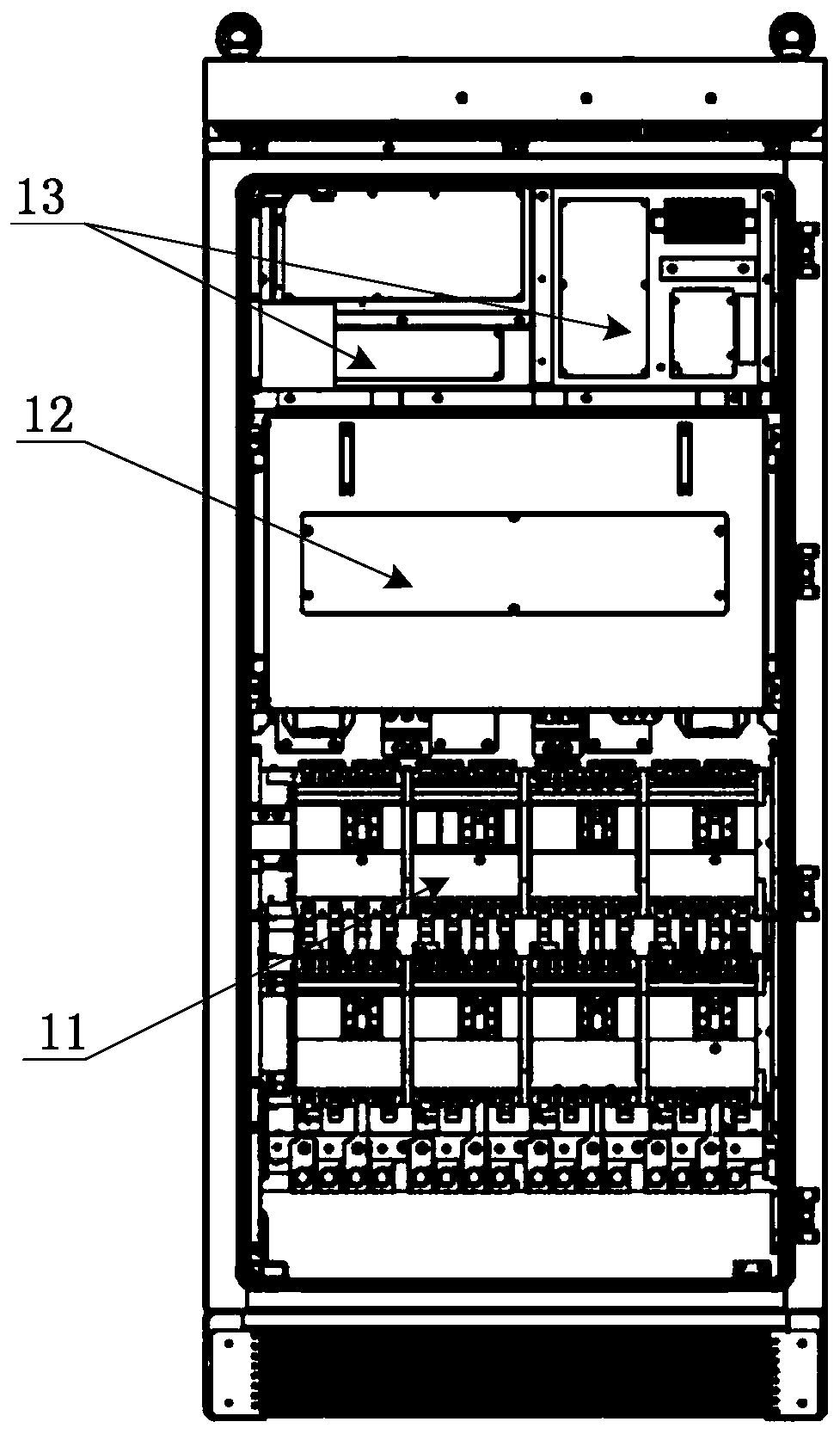

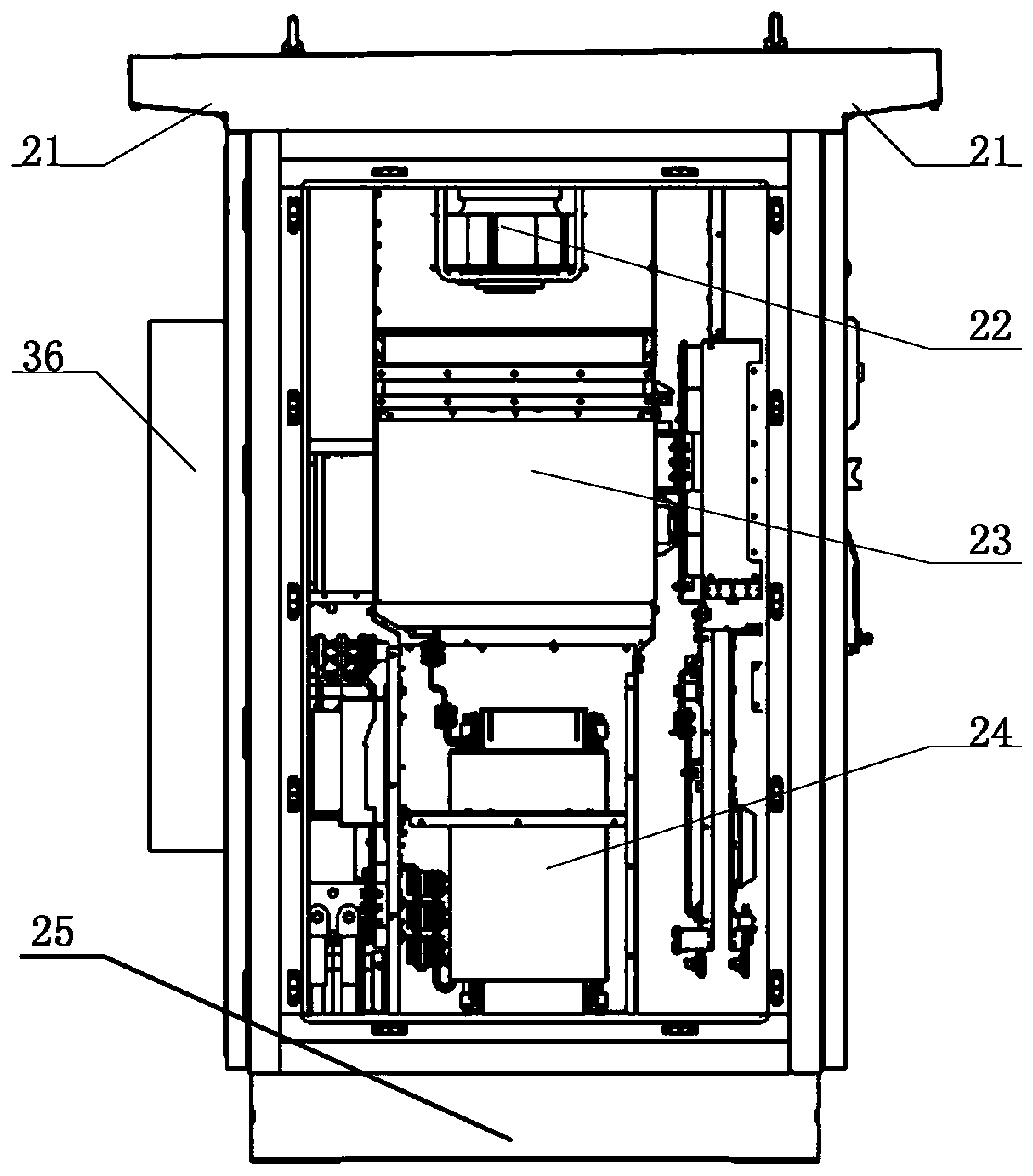

[0029] The present invention proposes an outdoor inverter unit that can realize multi-machine parallel connection. The inverter unit is composed of a DC chamber 1 , a power chamber 2 and an AC chamber 3 . The three cavities are sequentially placed in the front, middle and rear areas of the entire cabinet. The DC cavity 1 and the AC cavity 3 are connected through the left and right connecting air ducts of the AC cavity cabinet. The power cavity 2 is completely isolated from DC chamber 1 and AC chamber 3. The heat dissipation of the inverter unit is divided into two parts, which are power cavity heat dissipation and AC and DC cavity heat dissipation. The heat dissipation of the power cavity is to suck the external cold air from the air inlets on both sides of the top of the power cavity cabinet through the heat dissipation fan on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com