Shoe sole comprising additive manufacturing component

A technology of additive manufacturing and components, applied in the direction of shoe soles, footwear, applications, etc., to achieve the effect of improving overall elasticity, tight adhesion, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

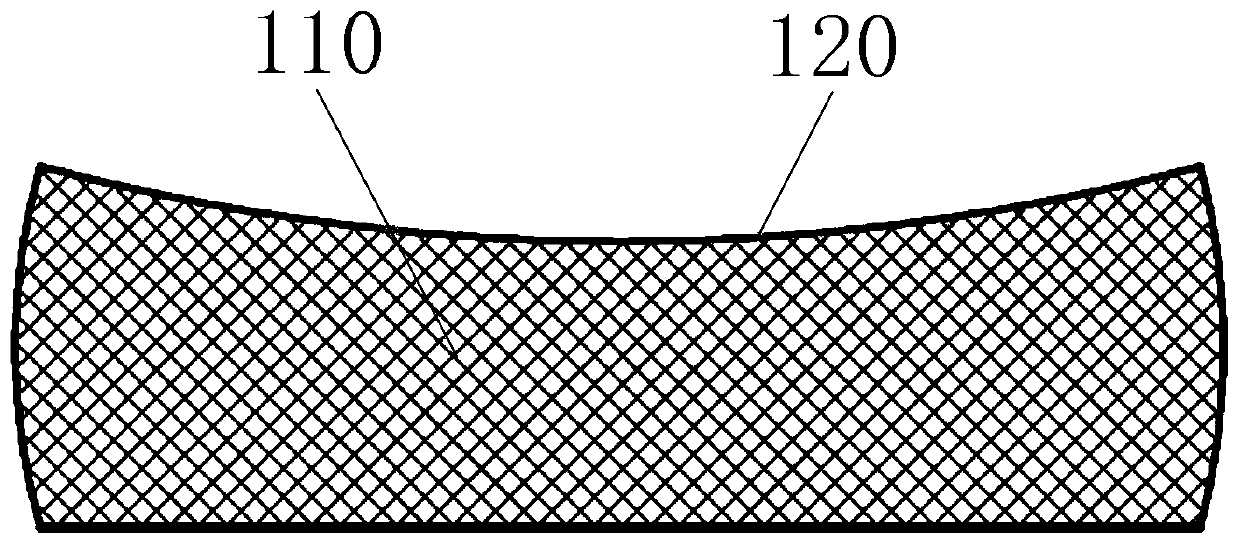

[0030] Embodiment 1 takes the shell 120 fully covering the additively manufactured component 110 as an example. If the exterior is fully covered, a closed space will be formed around the 3D printed midsole, which will also provide a better shock absorption experience. Because the coated material can further control the amount of deformation of the 3D printed structure, that is, change the shock absorption and elastic characteristics of the material.

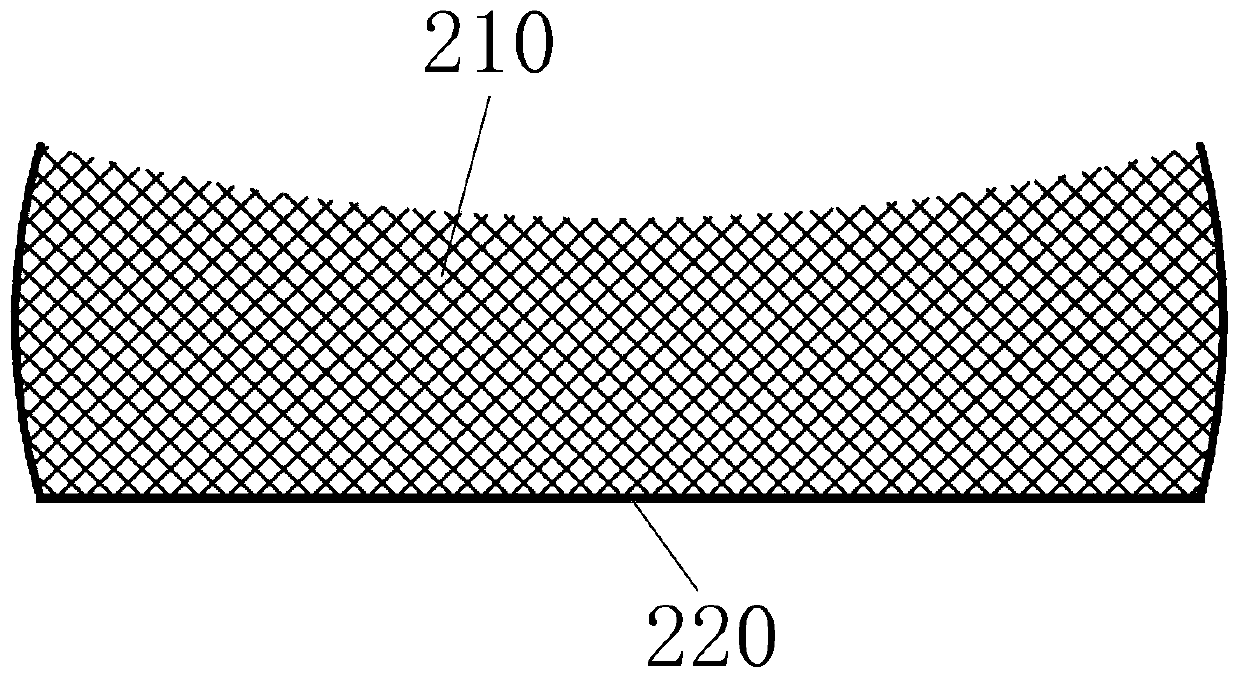

[0031] figure 2 A schematic structural diagram of a shoe sole including additively manufactured components provided for Example 2 of the present disclosure. like figure 2 As shown, the difference between the shoe sole including the additively manufactured parts of the second embodiment and the first embodiment is that the shell 220 partially covers the additively manufactured parts 210 .

[0032] The embodiment of the present disclosure proposes a shoe sole including additively manufactured parts, and a layer of other materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com