A Die Surface Compensation Method for the Thinning of Automobile Body Outer Panels

An outer cover, thickness reduction technology, applied in vehicle parts, forming tools, manufacturing tools, etc., can solve the problems of difficult control of mold quality and debugging cycle, high labor intensity of fitters, etc. The effect of reducing workload and shortening debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

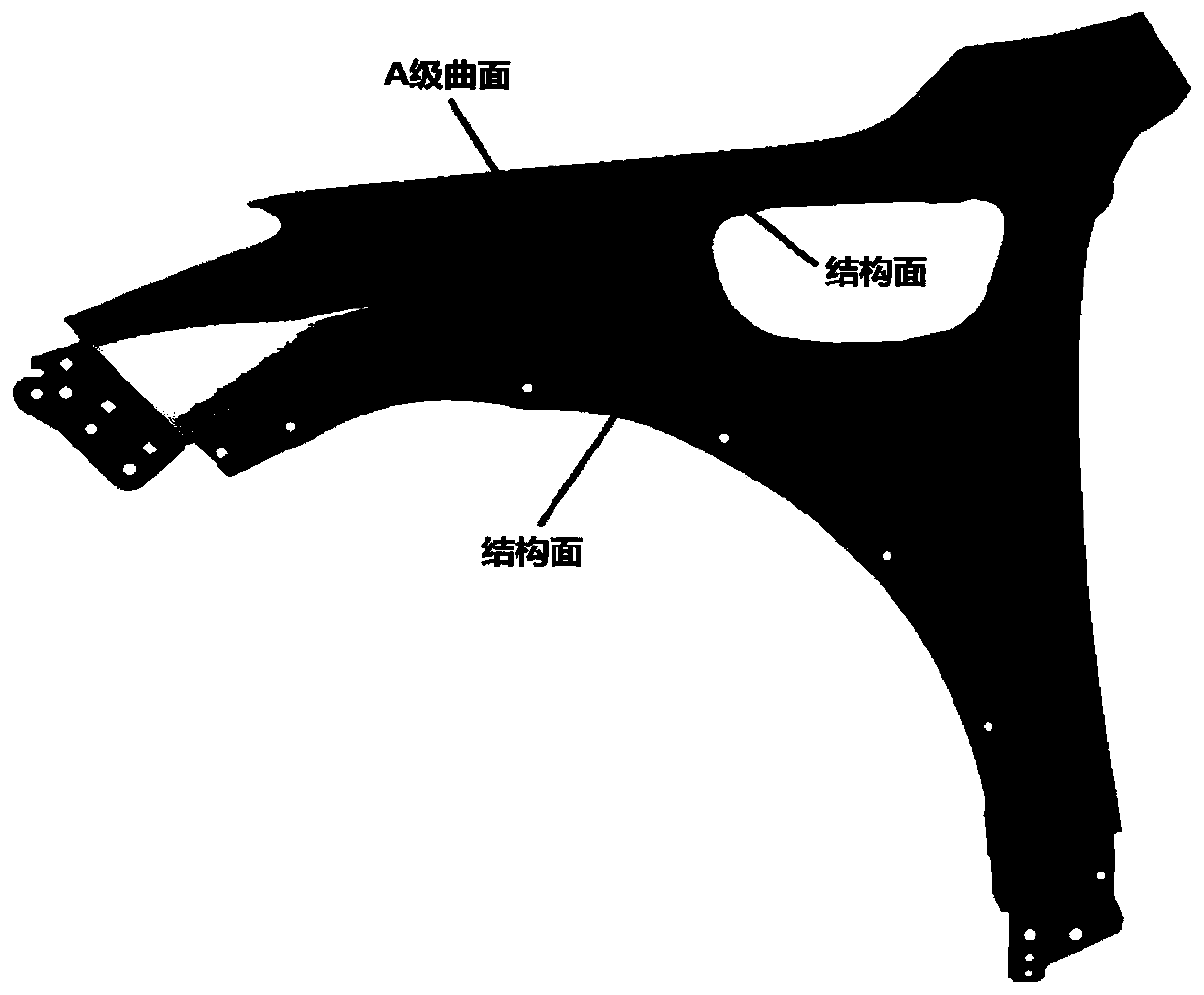

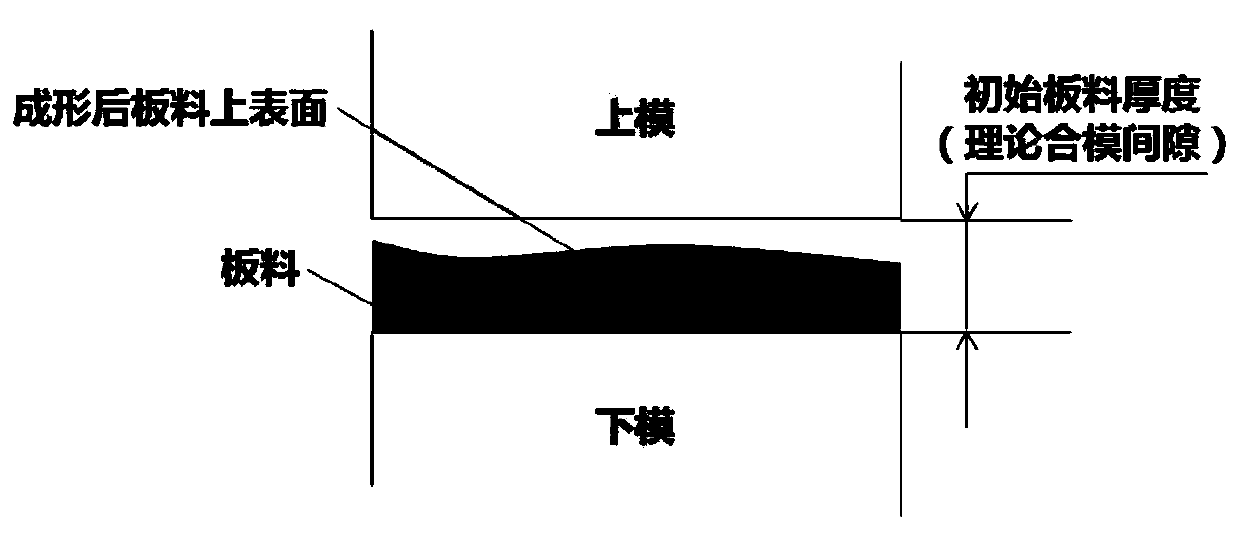

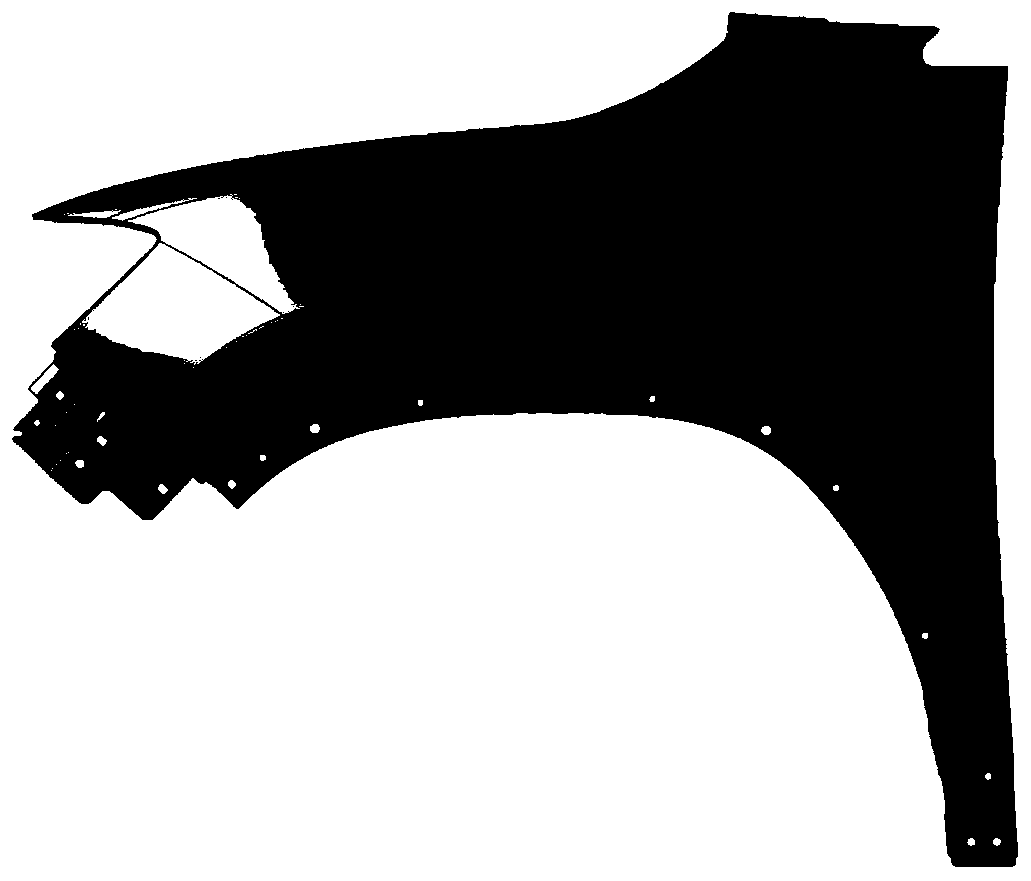

[0027] The product model of a car fender is as follows: image 3 As shown, the theoretical design thickness of the part is 1.1mm, and the material is 6014-T4 aluminum alloy plate. In the Autoform software, the simulation of the drawing process is carried out according to the content of the stamping process, and the cloud map of the thickness distribution of the drawn part after forming is obtained, as shown in Figure 4 As shown, there is uneven thickness reduction in the A-level curved surface area, and it is necessary to compensate for the thickness reduction of the mold surface. The steps are as follows:

[0028] The first step is to obtain the fender compensation benchmark grid data, the sub-steps are:

[0029] (1) Adjust the fender forming process in the Autoform software to the drawing end time node, and export the upper and lower surface grids of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com