Automatic tin immersion device and flat cable processing production line

A production line and immersion tin technology, which is applied in the direction of tin feeding devices, auxiliary devices, metal processing equipment, etc., can solve problems such as difficult to scrape off, low quality of wiring, incomplete tin scraping, etc., and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

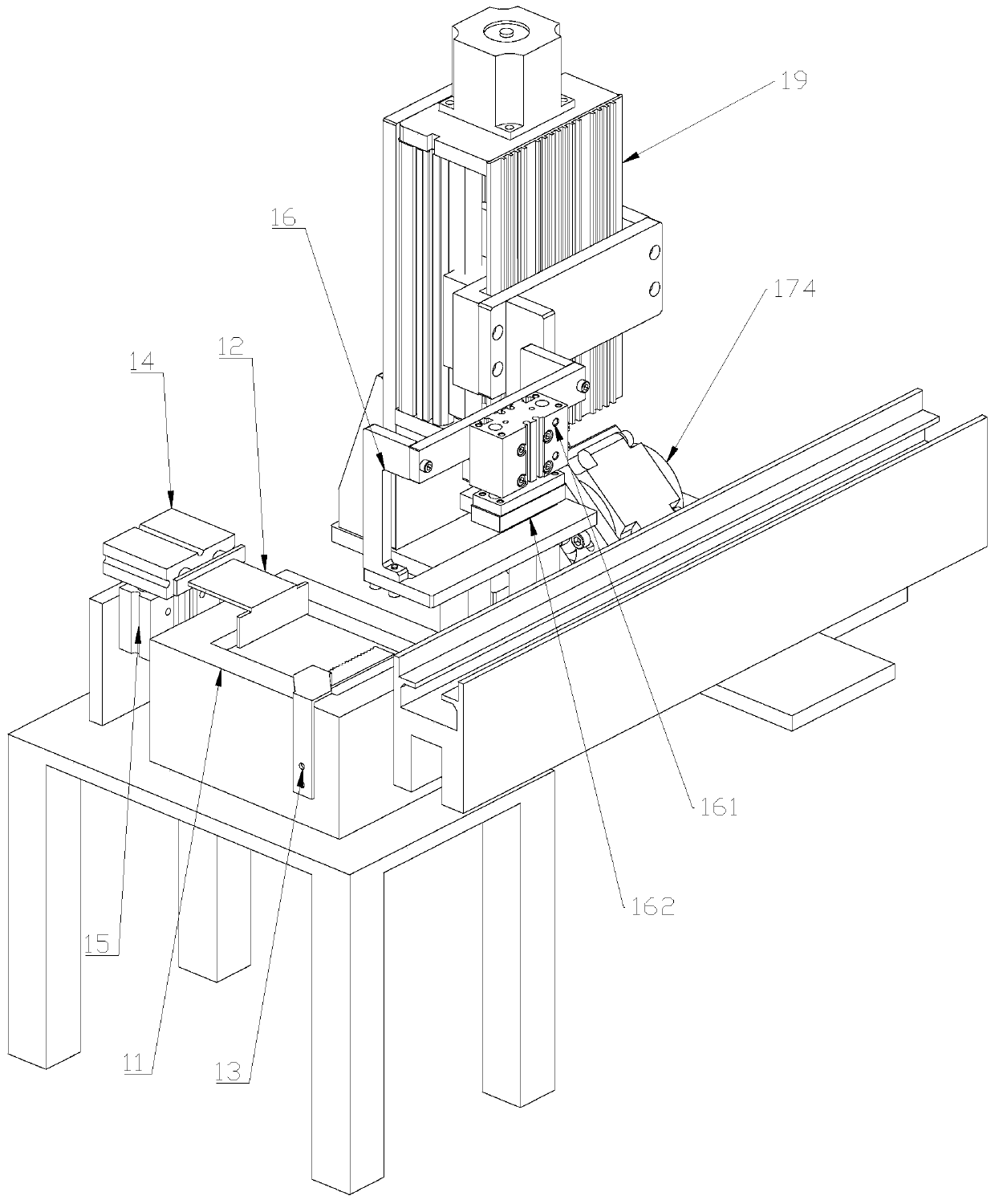

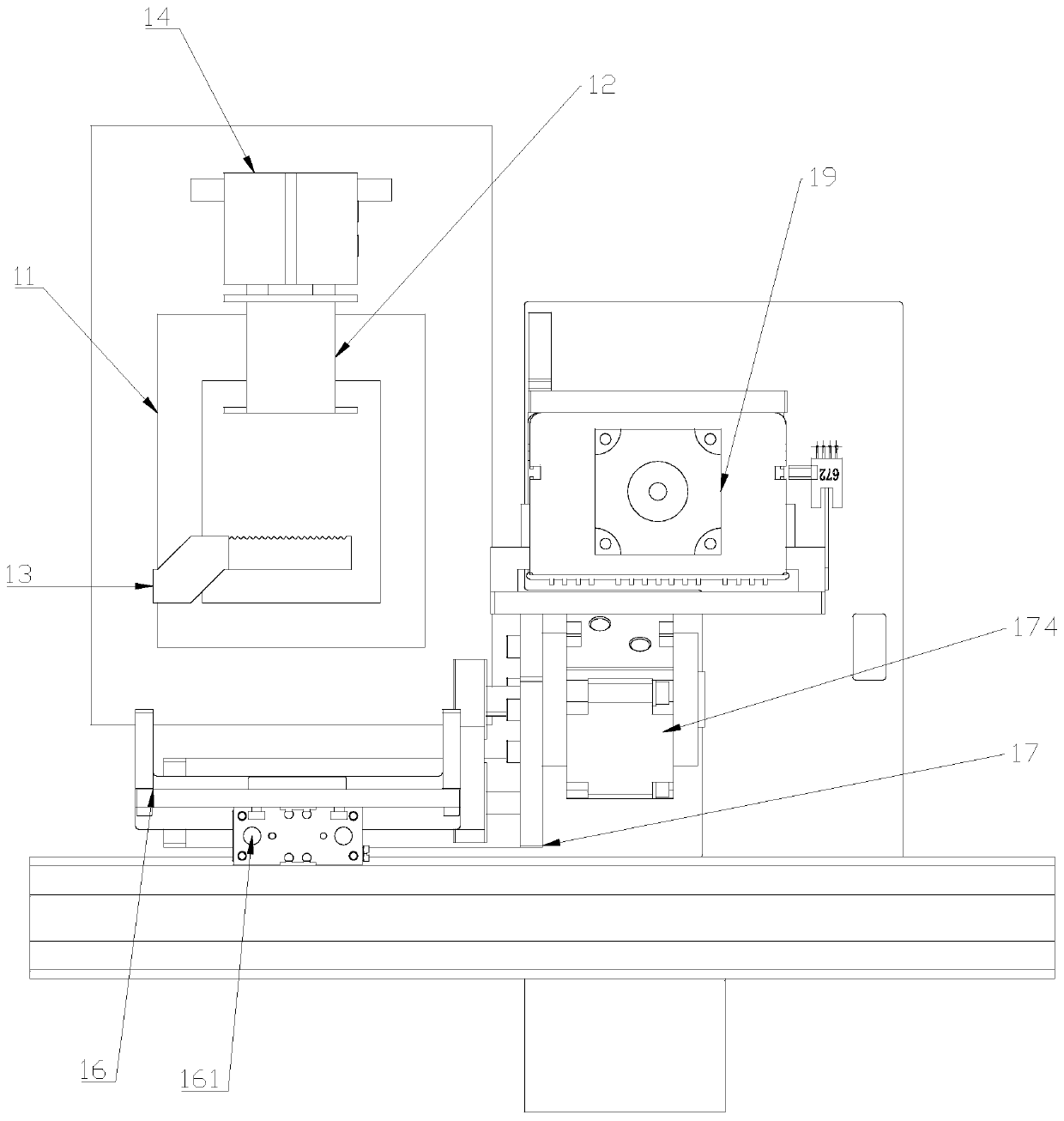

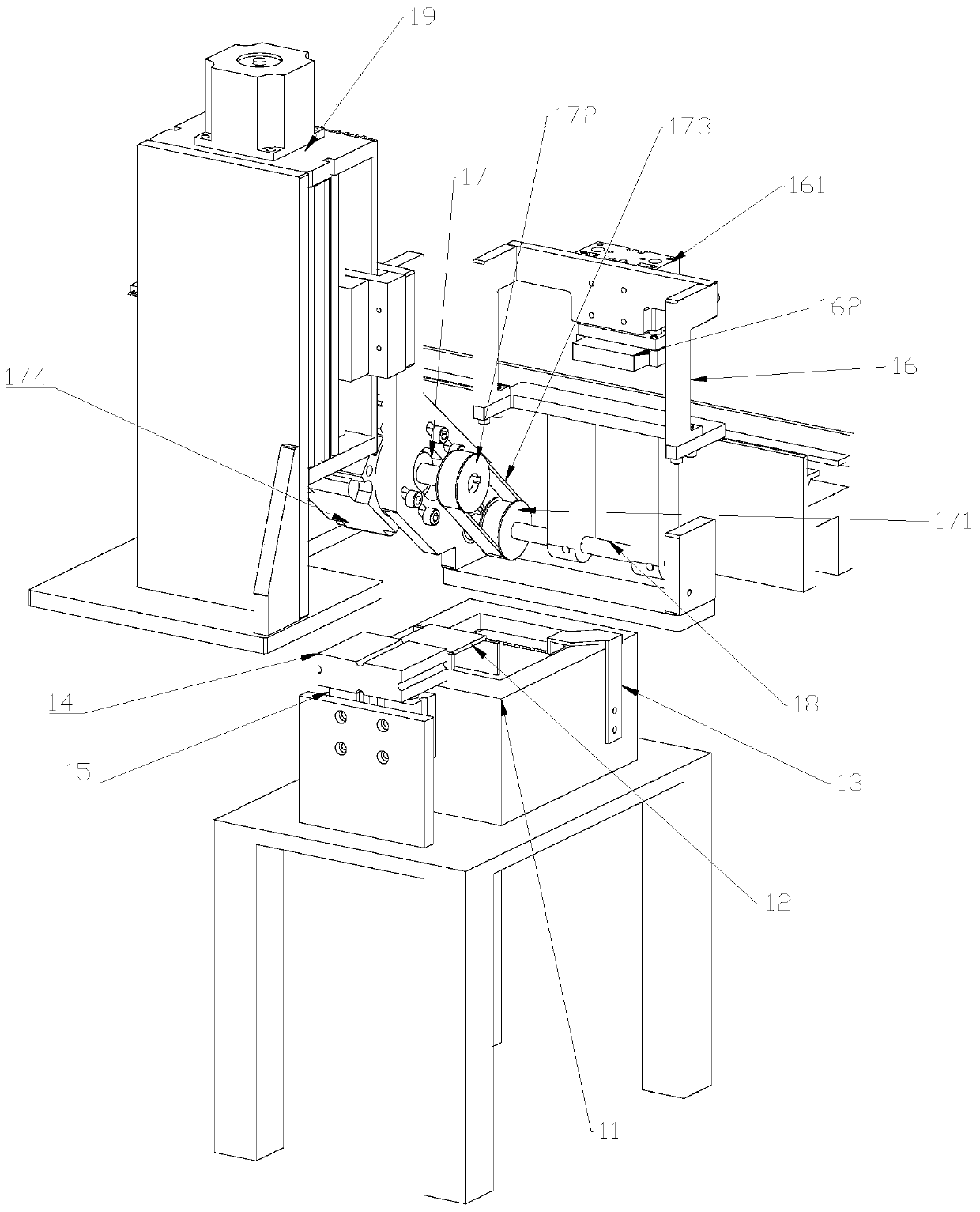

[0034] An automatic immersion tin device, such as Figure 1 to Figure 3, the overturning mechanism is connected to the PLC motor 19 as a whole, and the PLC motor 19 is fixedly set. When the automatic tin dipping device 1 works, the PLC motor drives the entire overturning mechanism to move upward for a certain distance until the horizontal end surface below the cross-shaped structure of the overturning part 16 and the clip The wire fixture 24 contacts, and then the third cylinder 161 on the turning part 16 pushes the splint 162 to move downward to clamp the wire clamping fixture 24; the PLC motor 19 drives the entire turning mechanism to move upward for a certain distance, so that the clamping fixture 24 times The end surface is away from the top of the positioning pin on the fixture base 23; the control part 17 drives the turning part 16 to turn 90 degrees toward the tin bath 11 through the synchronous toothed belt structure, so that the cable on the clamping fixture 24 is imme...

Embodiment 2

[0042] A line processing production line, such as Figure 4 and Figure 5 , including the above-mentioned automatic tin dipping device 1, the specific use process is the same, the automatic tin dipping device 1 is located on one side of the conveying track 2, and the other side of the conveying track 2 is fixedly installed with a sensor 21 and a limit baffle 22 and is connected with the automatic dipping tin Tin device 1 position is relative, and limit baffle 22 in the sensor 21 and limit baffle 22 is closer to the end of conveying track 2, and the bottom of limit baffle 22 is fixedly connected with the fourth cylinder that vertically arranges. In the free state, the limit baffle plate 22 is higher than the plane of the conveying track 2. When in use, the clamping fixture 24 is placed on the fixture base 23, and the fixture base 23 moves along with the conveying track 2. When the fixture base 23 moves When reaching the limit baffle 22, the fixture base 23 is blocked by the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com