Automatic feeding and cutting equipment for octagonal steel pipes

A technology for automatic feeding and cutting equipment, applied in metal sawing equipment, metal processing equipment, other manufacturing equipment/tools, etc., can solve problems such as non-polishing, uneven incision, worker injury, etc., to save production time and cost, Avoid the effect of uneven incision and simple working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

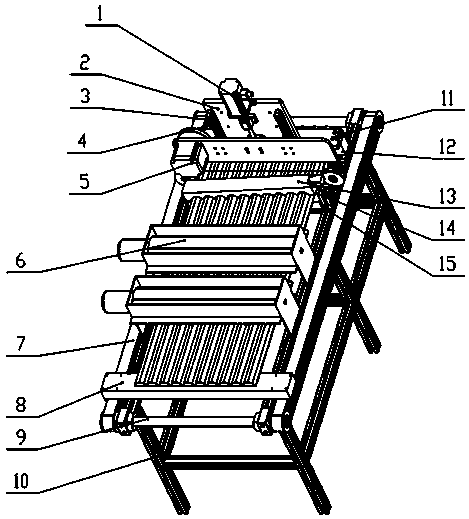

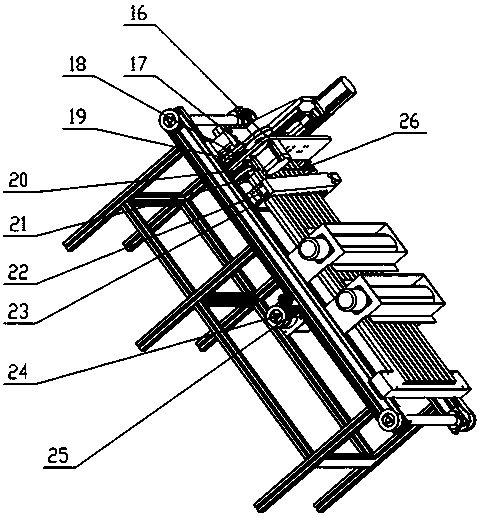

[0033] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

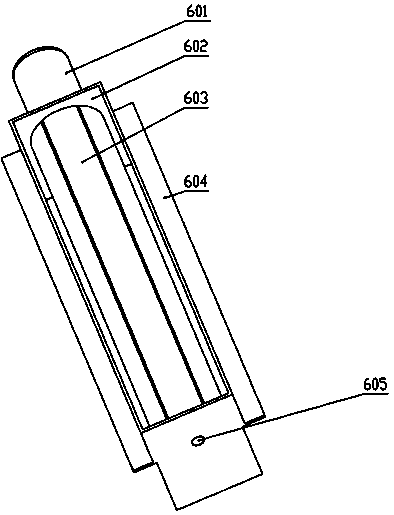

[0034] Examples, please refer to figure 1 , figure 2 with image 3 As shown, an octagonal steel pipe automatic feeding and cutting equipment includes: a support frame 10, the support frame 10 is spliced by several beams, and the two sides of the top are provided with flat plates, and the outer sides of the flat plates on both sides are equipped with feeding devices. A polishing device 6, a cutting fixture and a cutting device are slidably installed on the card slots of the flat plates on both sides, and a power cord and a control device are arranged on the side of the support frame 10;

[0035] The feeding device automatically sends the octagonal steel pipe to the bottom of the polishing device 6. The polishing device 6 polishes and cleans the octagonal steel pipe. After the feeding device sends t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com