Vehicle differential speed reduction device for multi-motor control, differential mechanism and vehicle

A deceleration device and multi-motor technology, applied in control devices, vehicle parts, transportation and packaging, etc., can solve problems affecting the reliability of the power system, gravity bias of differential speed reducer, large volume and weight, etc., and achieve novel design , improve reliability, and improve the effect of cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

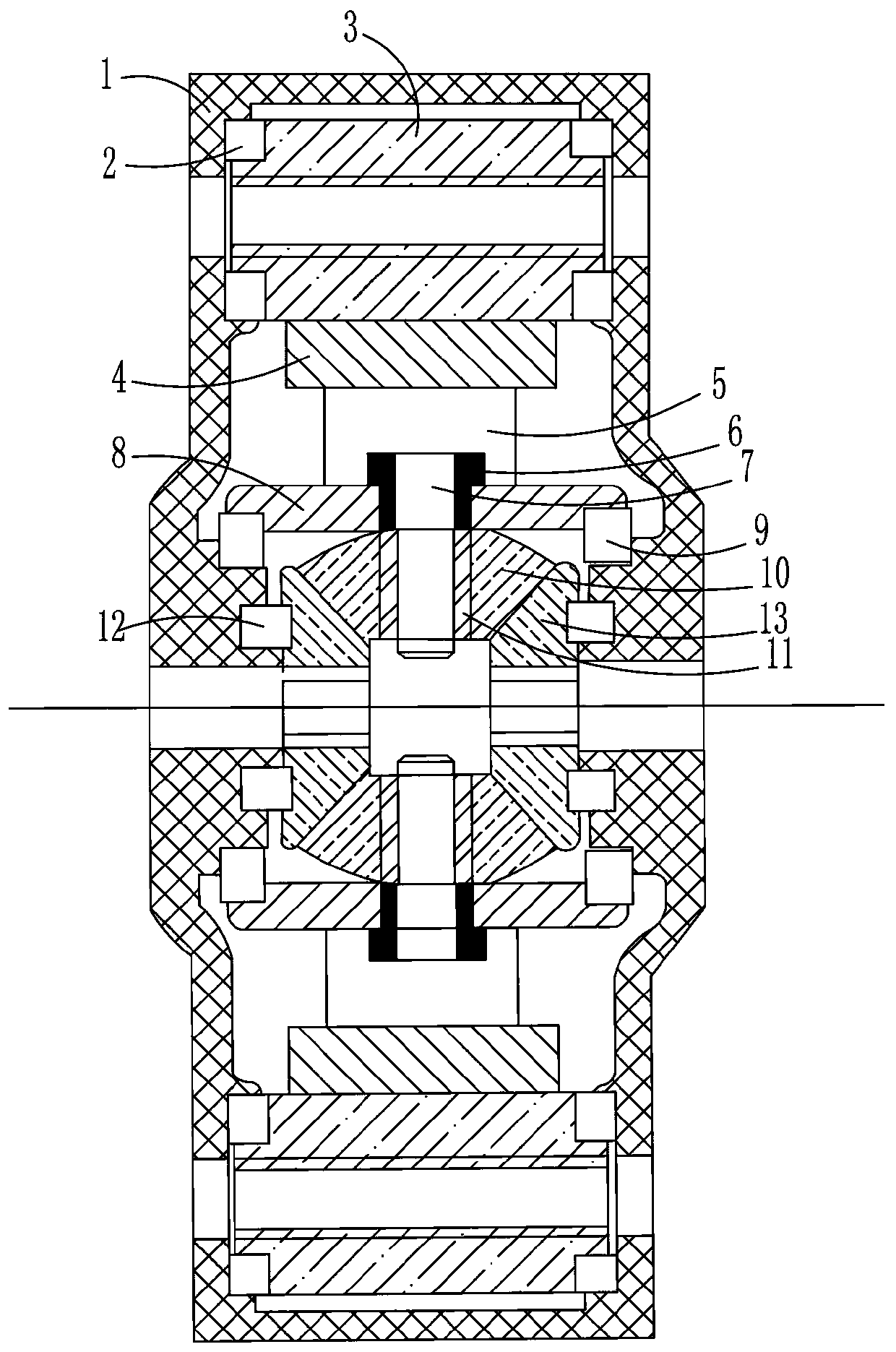

[0024] figure 1 Middle: Number 1 stands for housing, Number 2 stands for input gear bearing, Number 3 stands for input gear, Number 4 stands for passive ring gear, Number 5 stands for cross bracket of passive ring gear, Number 6 stands for pin sleeve, Number 7 stands for pin of planetary bevel gear , the number 8 represents the fixed ring of the planetary bevel gear, the number 9 represents the bearing of the fixed ring of the planetary bevel gear, the number 10 represents the planetary bevel gear, the number 11 represents the needle roller bearing, the number 12 represents the side shaft gear bearing, and the number 13 represents the side shaft gear;

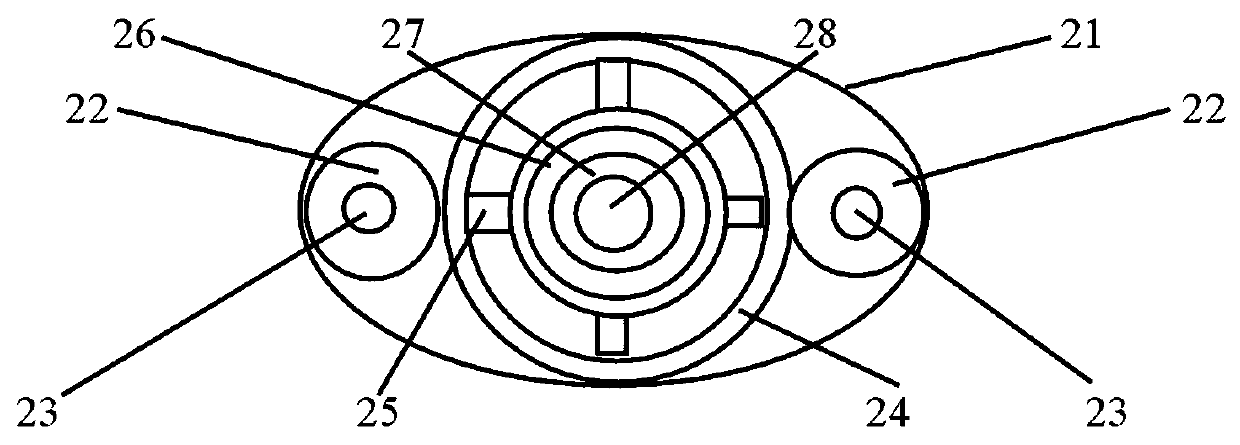

[0025] figure 2 Middle: The number 21 represents the housing, the number 22 represents the input gear, the number 23 represents the input gear hole, the number 24 represents the passive ring gear, the number 25 represents the cross bracket, the number 26 represents the fixed ring of the planetary bevel gear, and the number 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com