Flexible production system for beer production

A flexible production and beer technology, applied in synchronizing devices, bottle filling, bottling machines, etc., can solve the problems of profit loss not in line with production efficiency, long conversion time, no information exchange, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

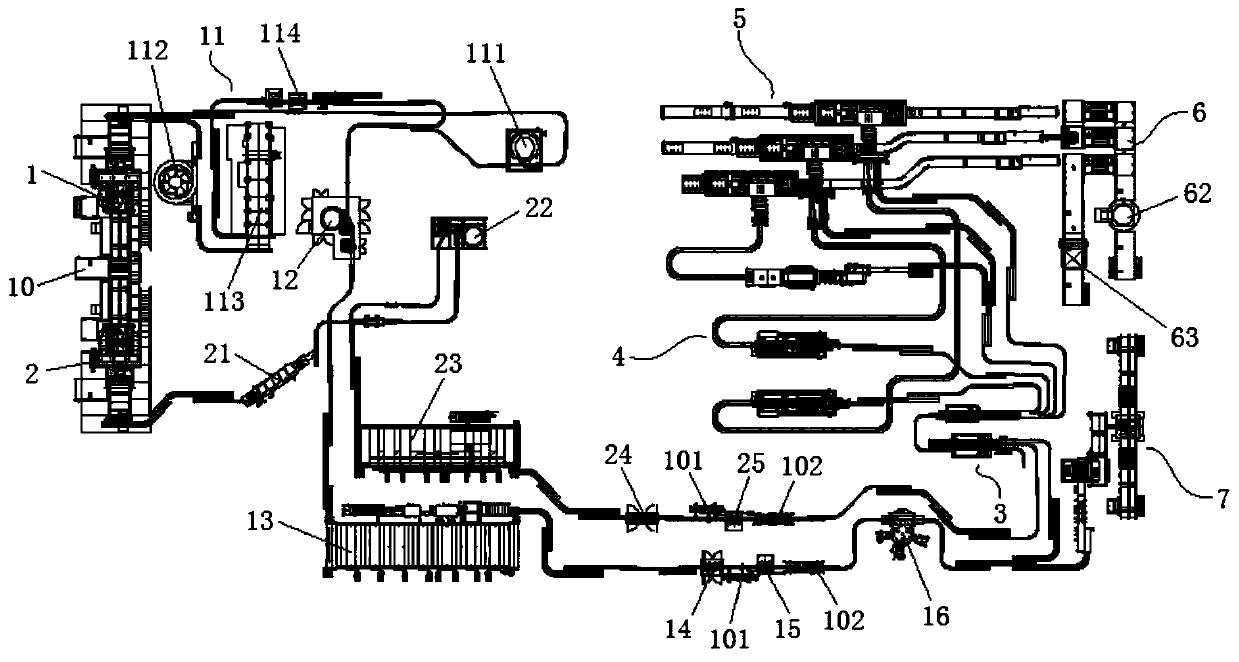

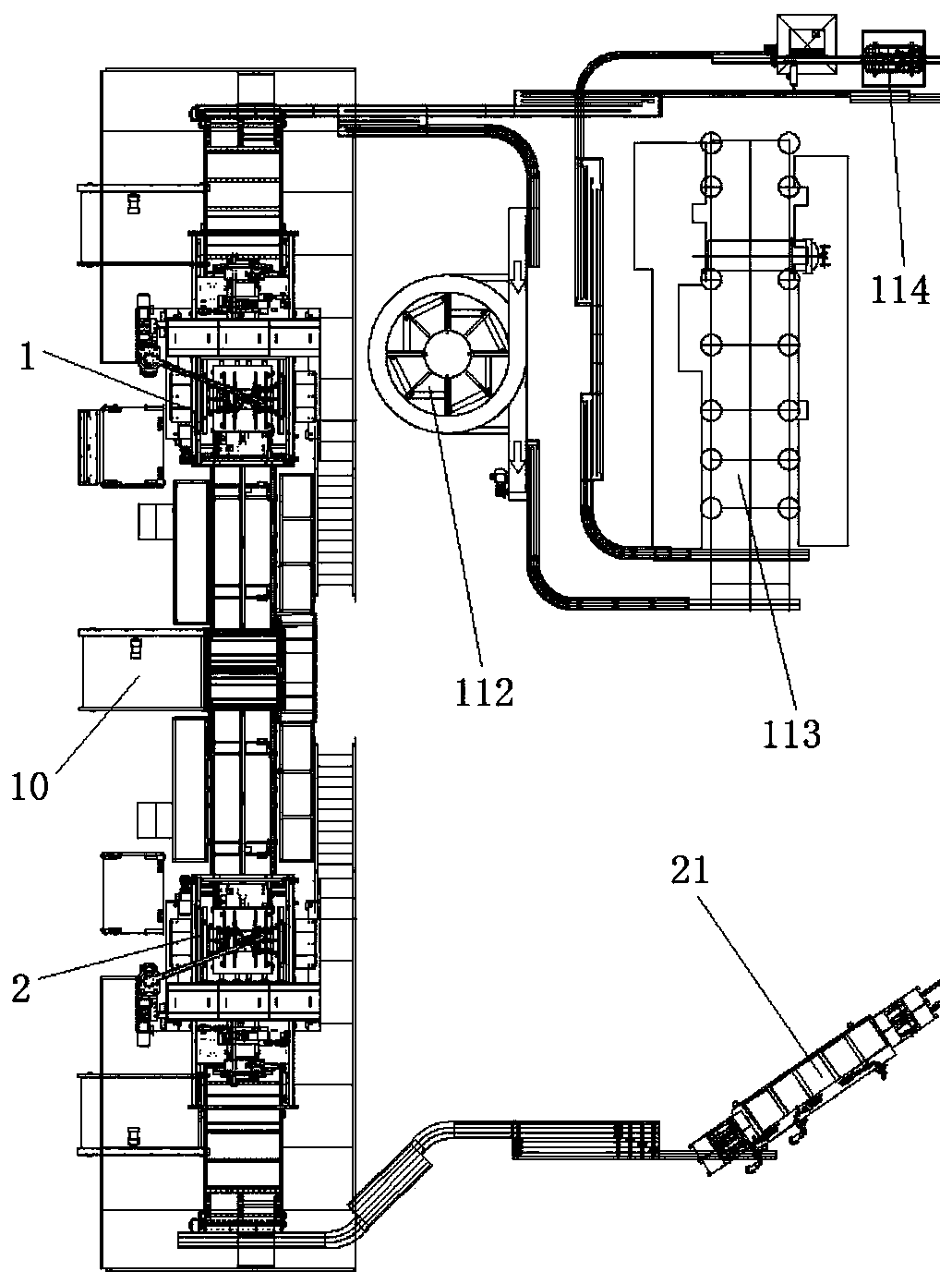

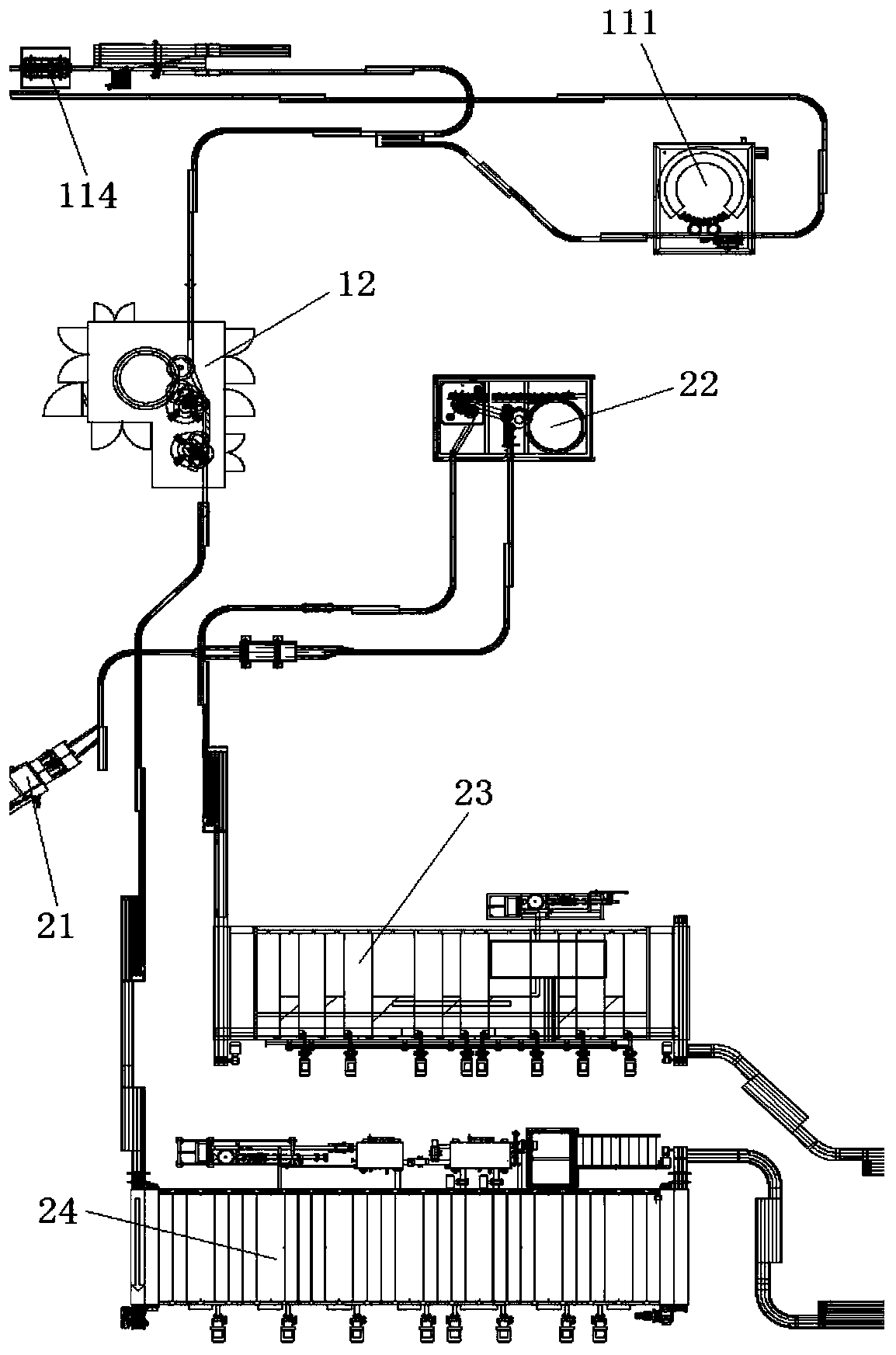

[0061] like Figure 1-14 As shown, a flexible production system that can be used for beer production is provided in this embodiment. Taking beer production as an example, it mainly includes a bottle unloading machine 1, a can unloading machine 2, a distribution and conveying device 3, a packaging system 4, and a case packing system 5 and palletizing system 6; as a preferred mode, the bottle unloading machine 1, can unloading machine 2, distribution conveying device 3, packaging system 4, case loading system 5 and palletizing system 6 are all electrically connected to the same control system , through the control system, each device is dispatched, coordinated and controlled. For the construction and setting of the control system, reference may be made to the prior art, which will not be repeated here.

[0062] The bottle unloader 1 and the can unloader 2 are arranged side by side in the word "one", as figure 1 , figure 2 As shown, the inlet conveyor belt 10 of the product to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com