Novel wool top unreeling and feeding device

A technology for feeding device and tops, which is used in textile and papermaking, fiber processing, combing machines, etc., can solve the problems of lack of top tension adjustment function, lack of top roll lifting device, inconvenient top roll limit fixation, etc. , to achieve the effect of increasing convenience, reducing workload, and preventing accidental injury to personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

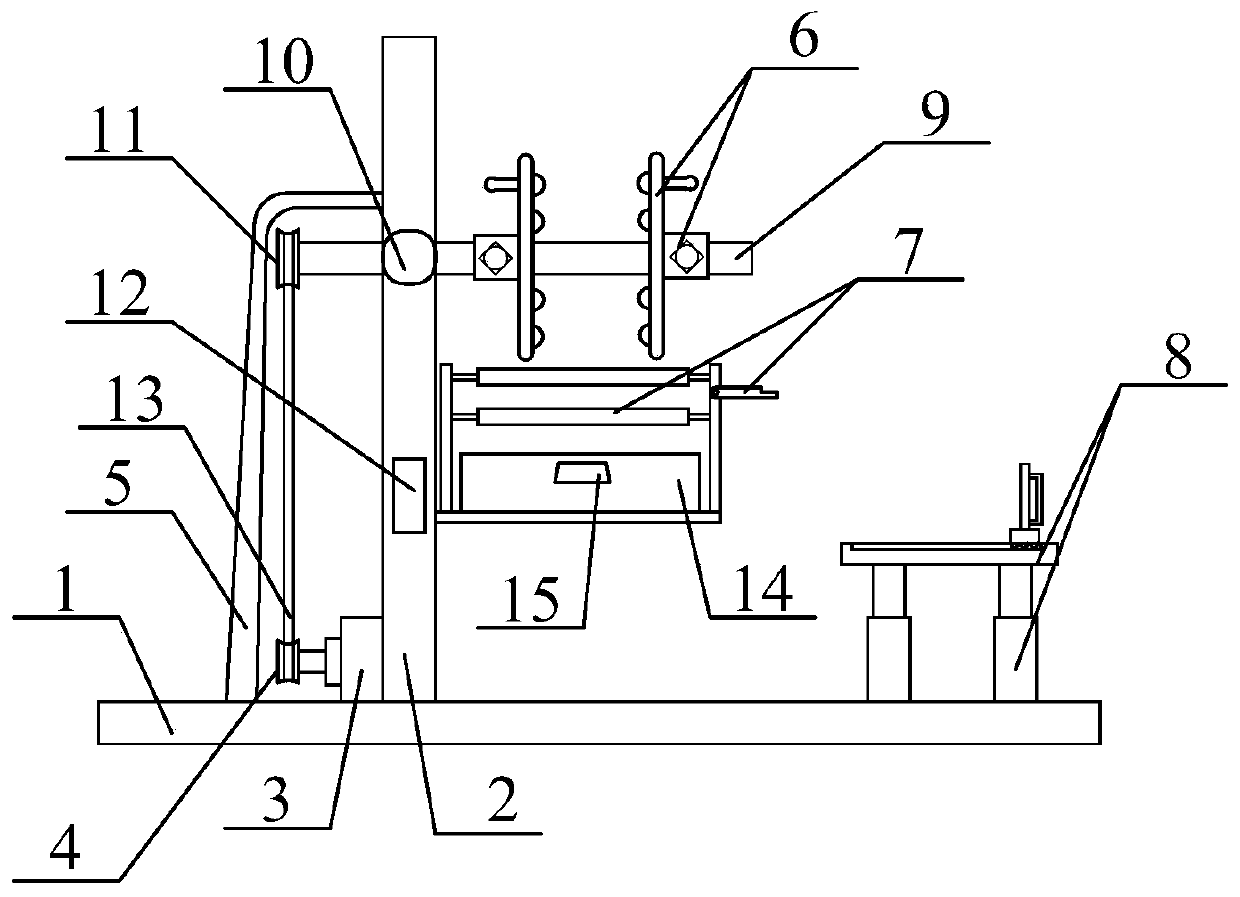

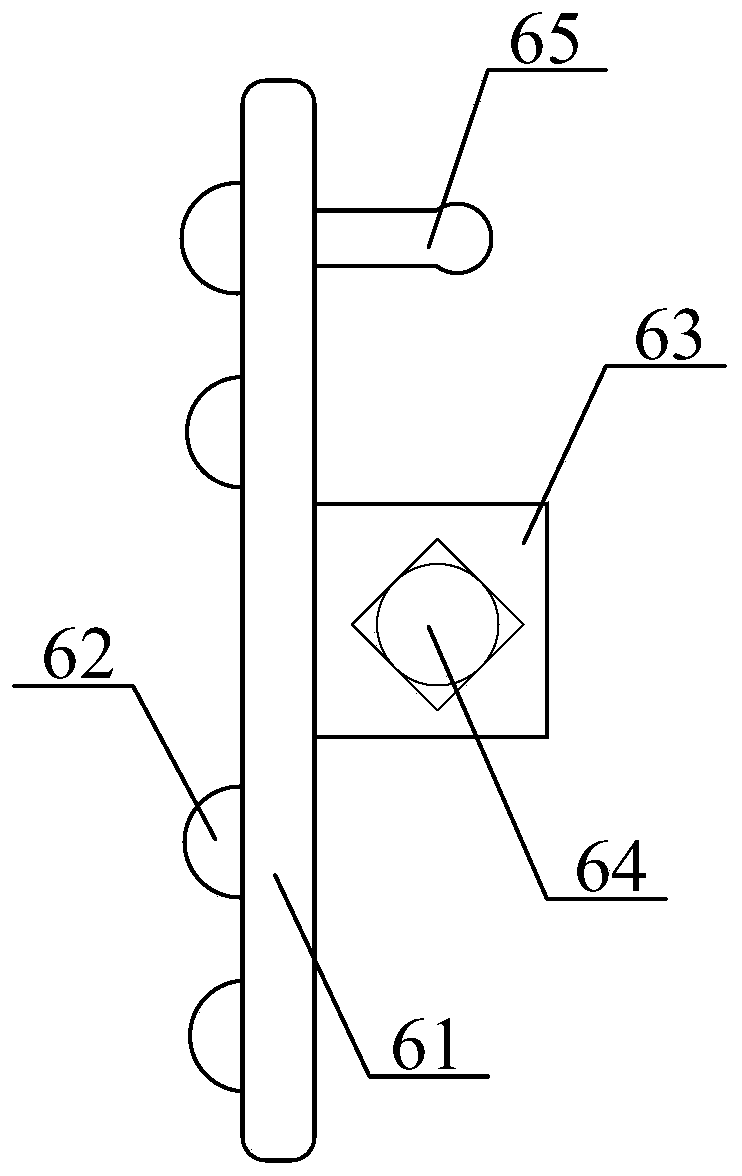

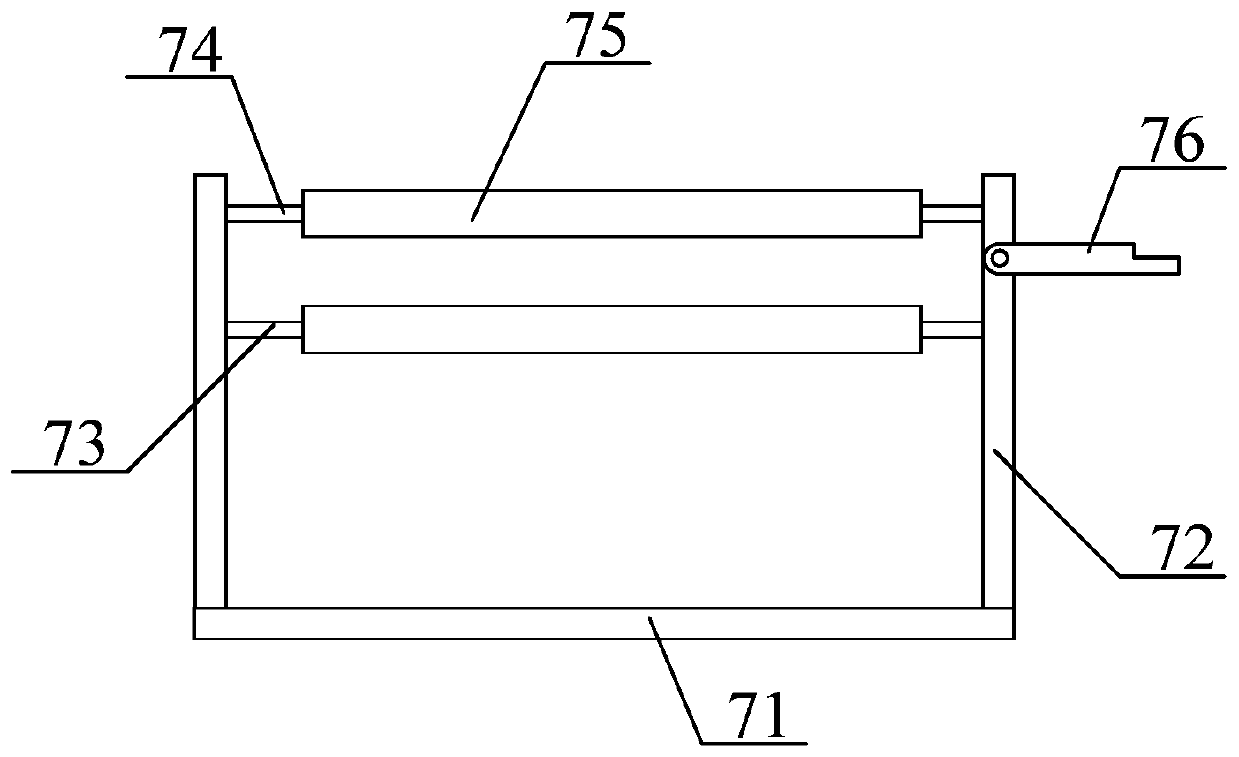

[0034] as attached figure 1 to attach figure 2As shown, the present invention provides a novel wool top unwinding and feeding device, including a support base plate 1, a support column 2, an unwinding and feeding motor 3, a driving pulley 4, a belt guard 5, and an adjustable wool top roll limit stop plate Structure 6, Cuttable top tension adjustment frame structure 7, Liftable top roll installation platform structure 8, Unwinding shaft 9, Ball bearing 10, Driven pulley 11, Control box 12, Driving belt 13, Shavings collection box 14 and the pulling handle 15, the support column 2 is bolted to the left side of the upper surface of the support base plate 1; the unwinding and feeding motor 3 is bolted to the middle position on the rear side of the upper surface of the support base plate 1; The drive pulley 4 is key-connected to the output shaft of the unwinding and feeding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com