Pile cap foundation structure and construction method thereof

A technology of foundation structure and construction method, applied in the direction of foundation structure engineering, construction, etc., can solve problems such as reducing the lateral support of concrete piles, potential safety hazards, and dislocation of prefabricated piles, so as to improve the compressive strength and the ability to bear external loads. Safety and stability, the effect of reducing the resistance of pile delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

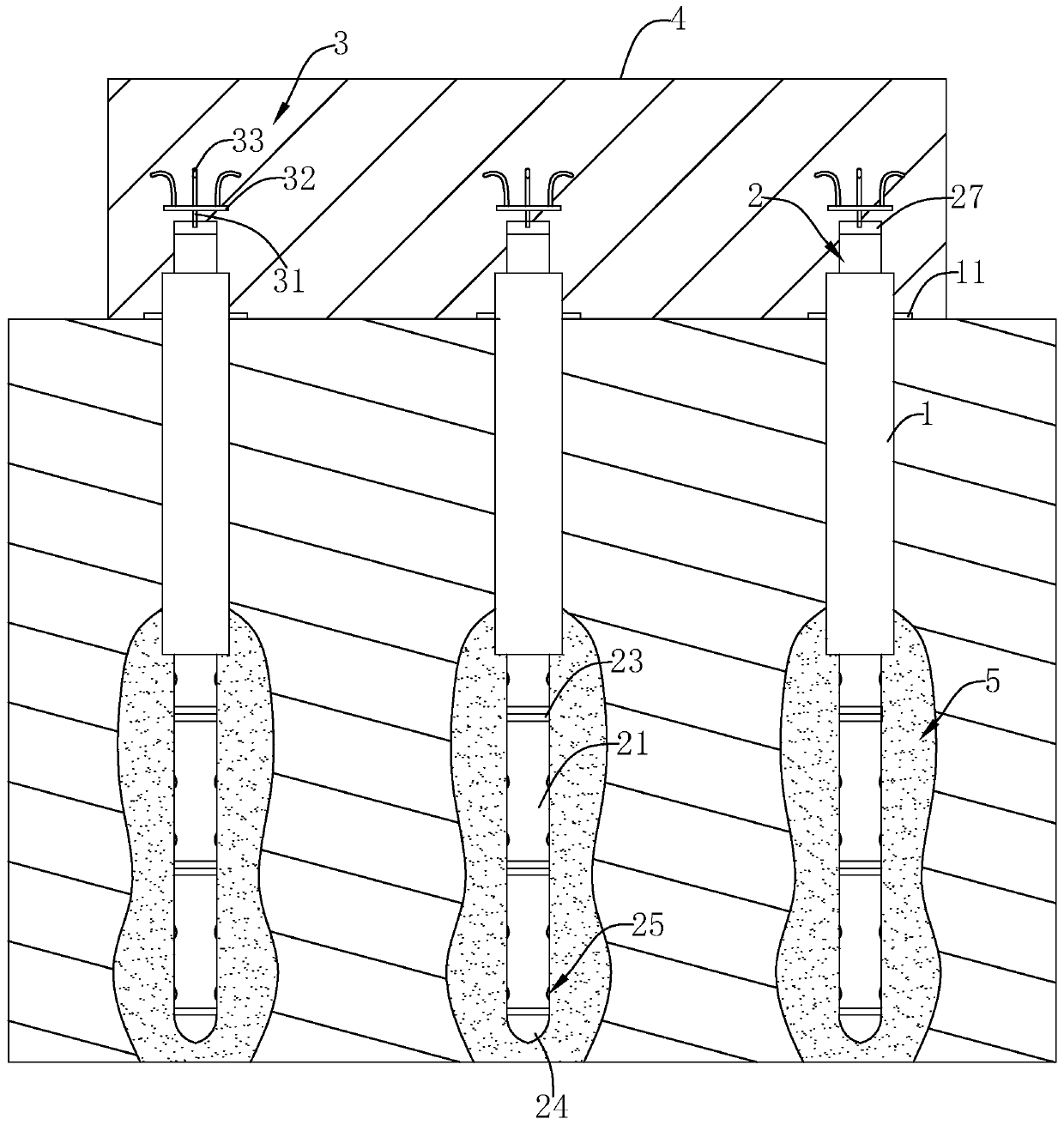

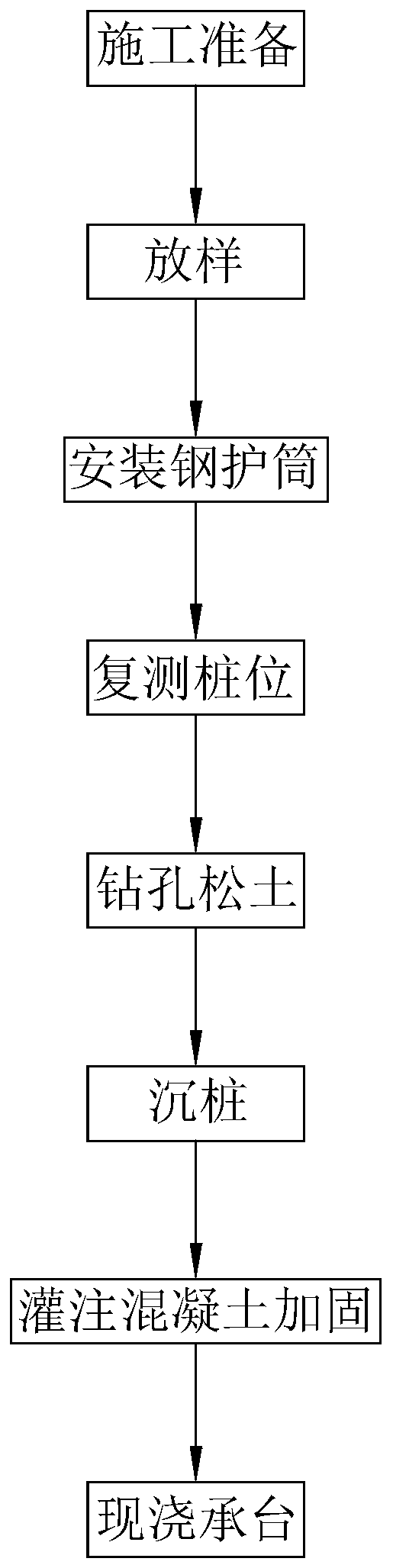

[0049] refer to figure 1 , is a pile cap foundation structure disclosed by the present invention, comprising a steel casing 1, a concrete pile 2, a steel anchor 3 and a cap 4, wherein the inner diameter of the steel casing 1 is compatible with the outer diameter of the concrete pile 2 It is used for positioning and guiding the construction of the concrete pile 2. On the outer wall of the steel casing 1 above the ground surface, there is a circle of flange 11 fixedly connected, which overlaps on the ground to support the cylinder, and the lower surface of the flange 11 is coated with water-swellable sealant to prevent Surface water seeped out. During installation, excavate the soil within the buried range of the steel casing 1 by a drilling rig, hoist the steel casing 1 in place by hoisting, and then fix it by applying mortar around the steel casing 1 .

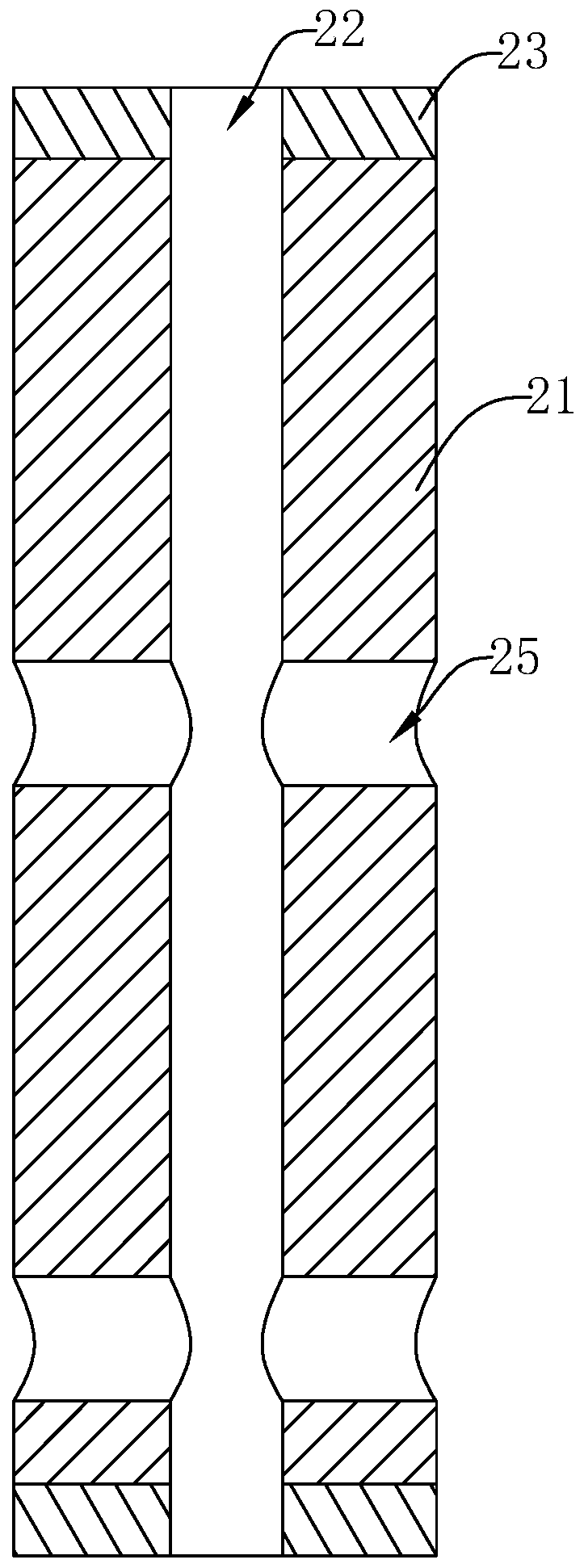

[0050] There are multiple concrete piles 2, one of which is taken as an example in this embodiment for illustration. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap