Building steel structure support device

A technology of structural support and construction steel, which is applied in the direction of building construction and construction, can solve the problems of cumbersome installation process and high installation cost, achieve the effect of simple disassembly and assembly, simple structure and improved support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 2

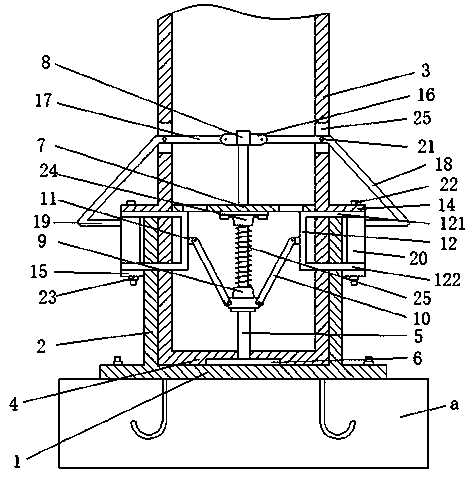

[0025] First, according to the construction specification, the strip foundation a is formed by pouring on the leveled foundation at one time. During the process of pouring the strip foundation, the embedded parts 1 are embedded to the predetermined position. After the strip foundation a is completely solidified, the steel structure can be carried out. The installation of the support part is completed;

[0026] When installing, insert the end of the steel column 3 into the positioning sleeve 2 first. During the insertion process, the drive plate 6 will first come into contact with the top surface of the embedded part 1, and will be locked with the downward movement of the steel column 3. The seat 9 and the upper locking seat 8 rise;

[0027] During the rising process, the lower locking seat 9 pushes the card seat 12 to move horizontally outward through the first driving link 10, so that the upper clamping plate 121 and the lower clamping plate 122 pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com