Import-type hammering riser joint

A riser and hammering technology, which is applied to drilling pipes, casings, drilling equipment, etc., can solve the problems of inability to complete the connection of threaded hammering risers and hammering, so as to improve drilling efficiency and solve on-site operations. difficult and convenient on-site maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

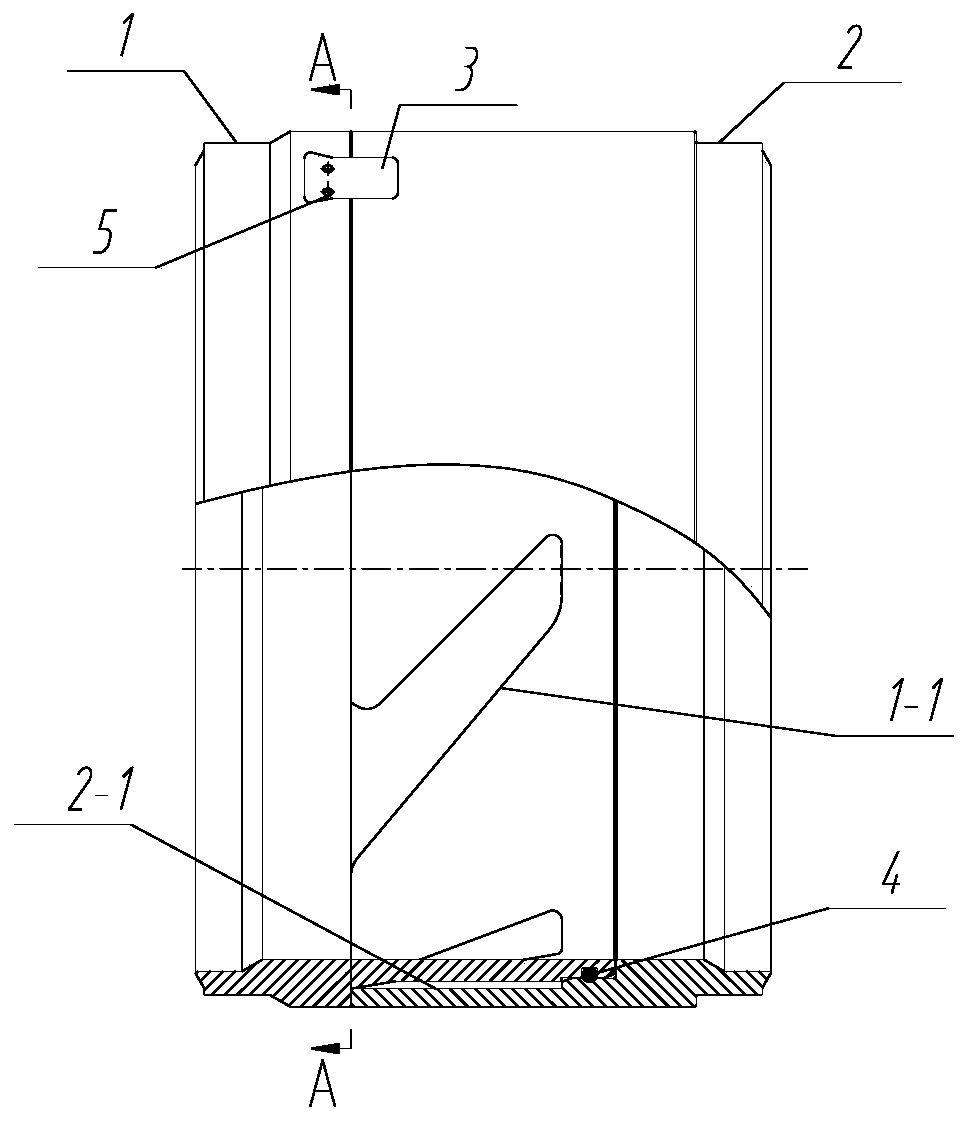

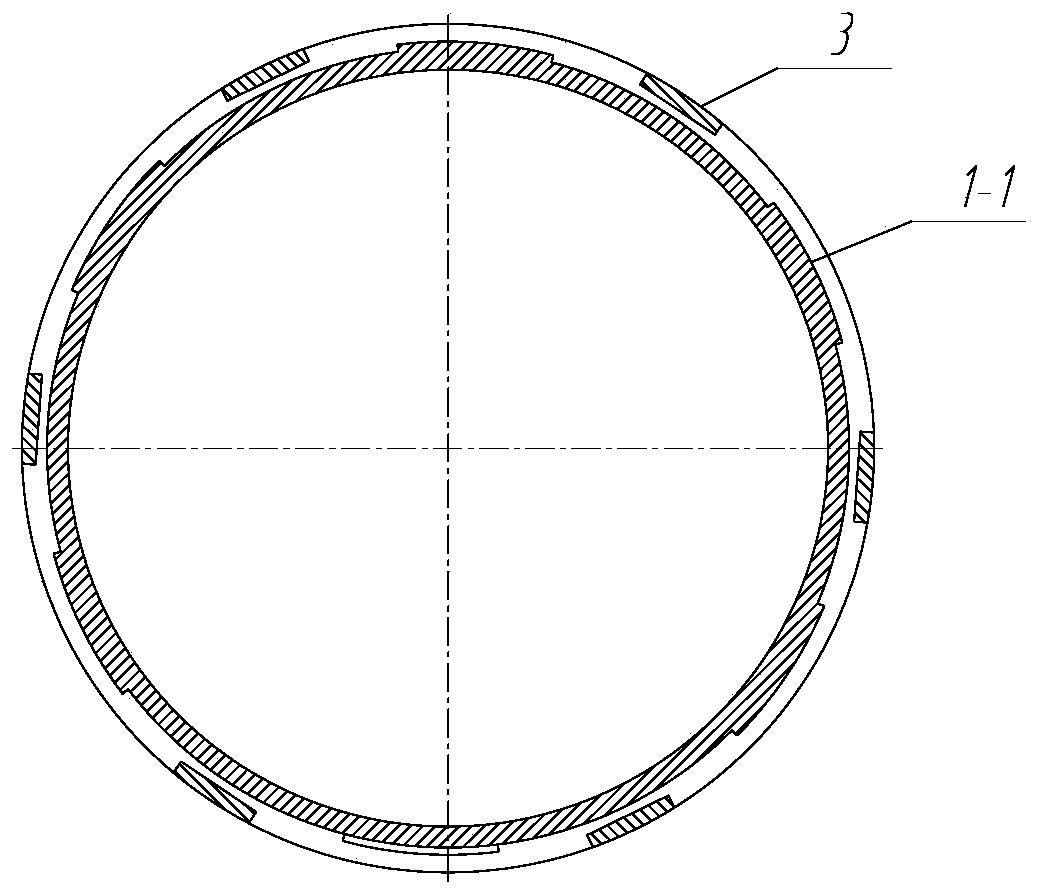

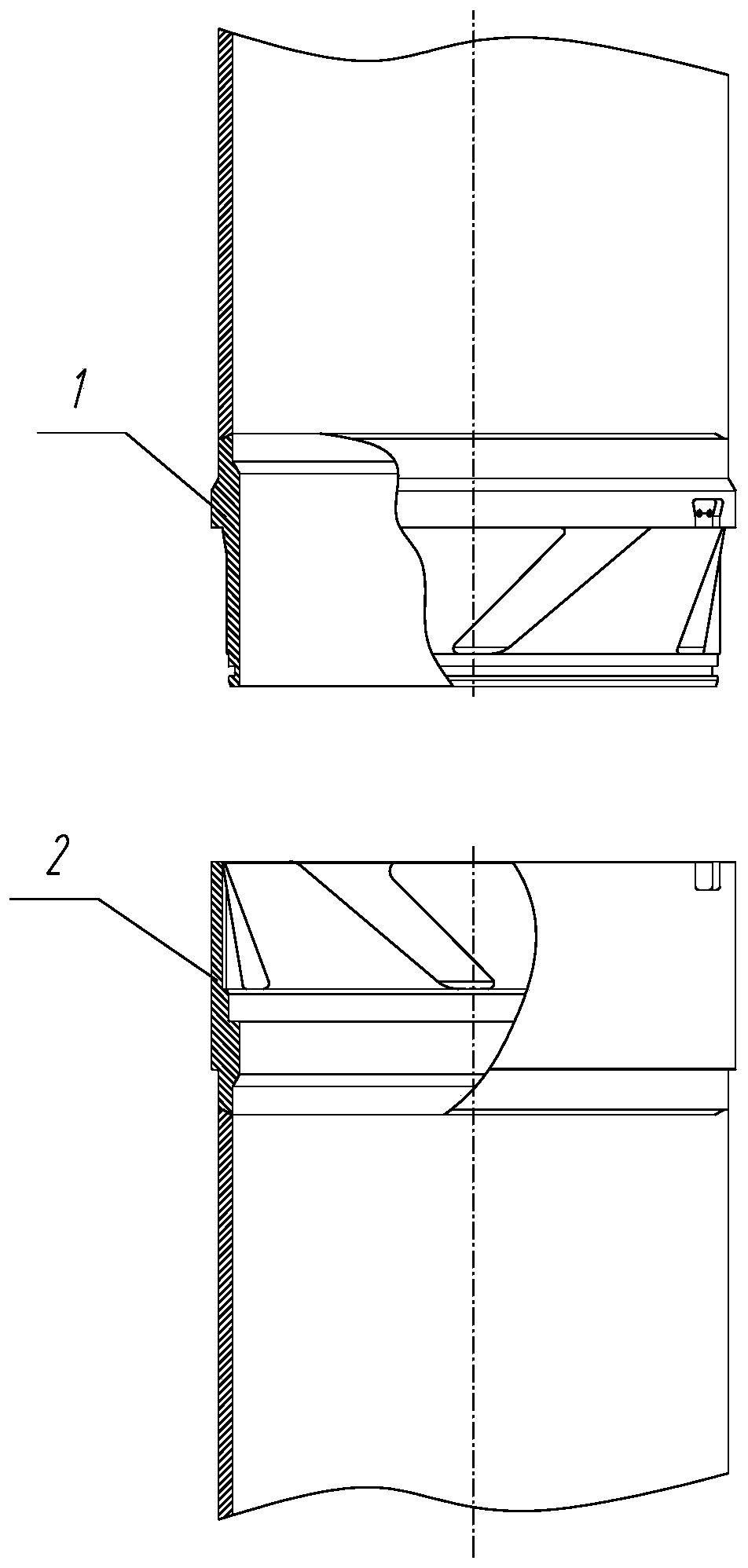

[0015] see Figure 1 ~ Figure 3 , a lead-in hammer riser joint, comprising an inner joint 1 and an outer joint 2 butted up and down, the middle and lower part of the inner joint 1 is inserted into the outer joint 2, and the middle and lower part of the inner joint 1 is provided with There are a plurality of helical teeth 1-1 evenly distributed along the circumferential direction, and a plurality of helical alveoli 2-1 are arranged inside the outer joint 2, and the inner joint 1 and the outer joint 2 are connected through the alveoli, The helical teeth 1-1 of the inner joint 1 are automatically introduced into the helical alveolar 2-1 in the outer joint 2 under the action of gravity, so as to realize the engagement of the helical teeth 1-1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com