Pot rack for preventing fragmentation of glass panel and gas stove

A technology of glass panels and pot supports, which is applied in the field of kitchen pots and stoves. It can solve problems such as single structure, broken glass panels, and temperature rise at the bottom of pot supports, and achieve the effects of reducing conduction, preventing excessive temperature, and preventing fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

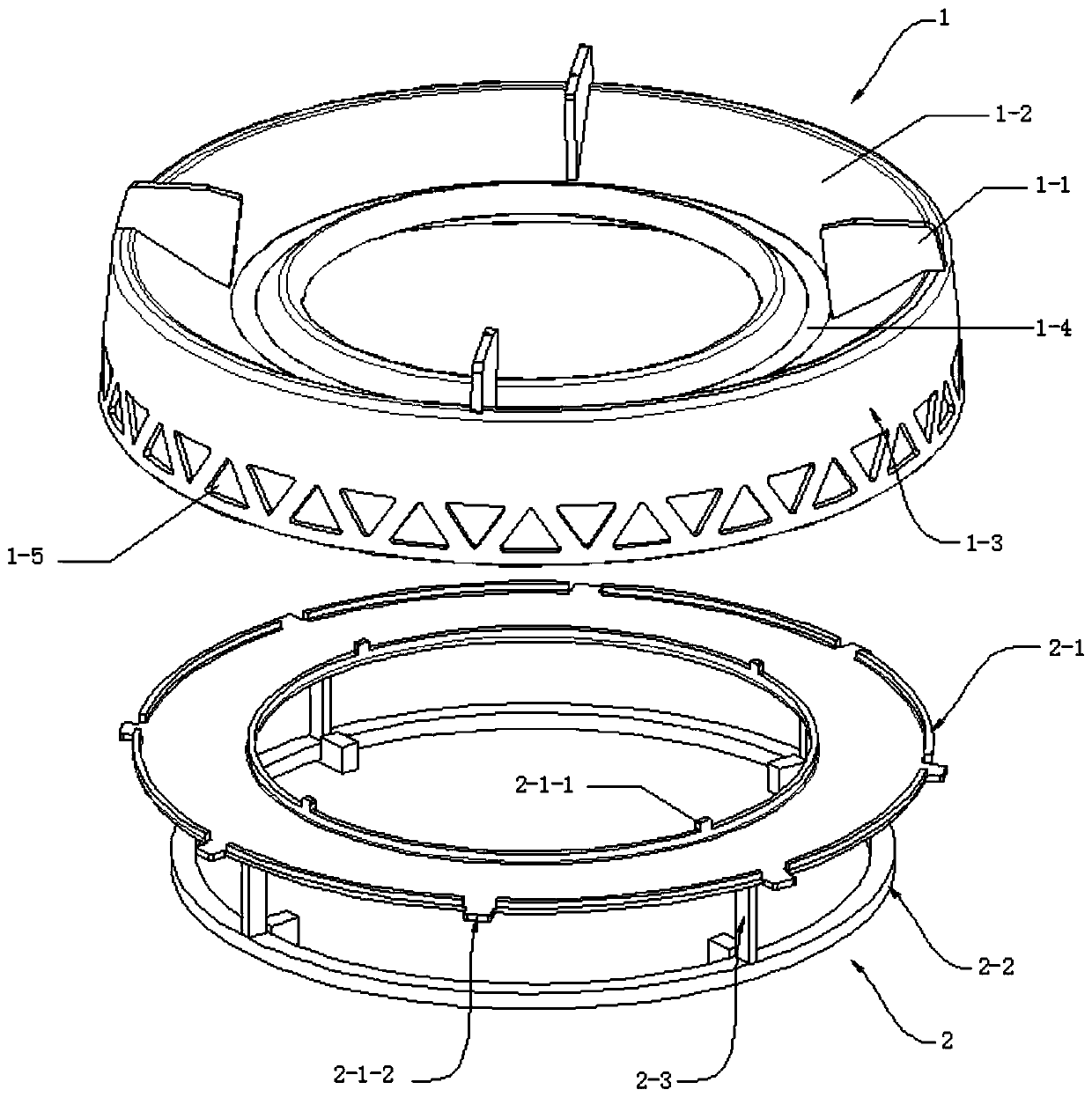

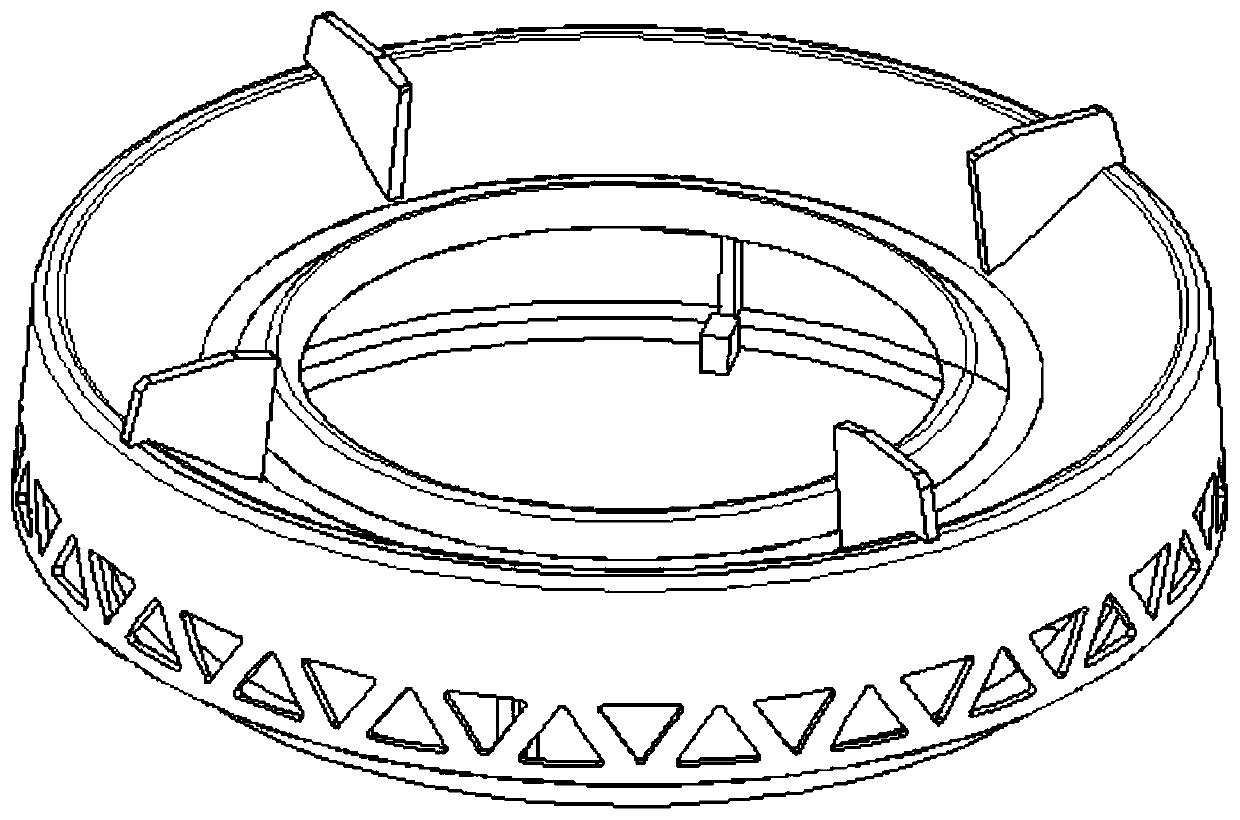

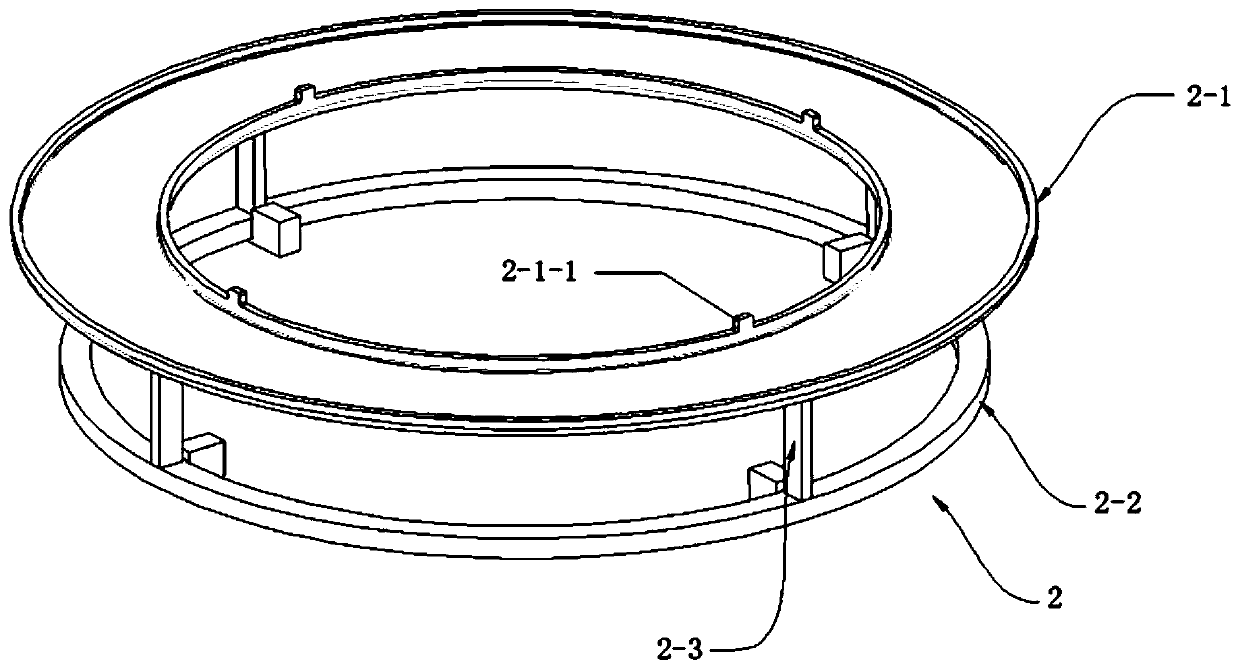

[0026] like figure 1 As shown, the present invention is a pot support for preventing glass panels from breaking, comprising an upper pot support 1 in contact with the pot and a lower pan support 2 supporting the upper pan support 1, and the lower pan support 2 includes a spacer 2-1 , the bottom ring 2-2 and the pot support legs 2-3, the spacer ring 2-1 is supported on the bottom ring 2-2 through four pot support legs 2-3, and the bottom of the pot support legs 2-3 is provided with Clamping groove, whose shape matches the bottom ring 2-2; the upper pot support 1 includes foot pieces 1-1, the upper pot support 1 is set on the spacer ring 2-1, and the upper pot support 1 is integrally cast and formed .

[0027] In the above example, a pot support for preventing glass panels from breaking according to the present invention is provided in the form of an upper pot support 1 and a lower pot support 2, and the spacer ring 2-1 of the lower pot support 2 passes through the pan support ...

Embodiment 2

[0031] The invention discloses a pot stand for preventing glass panels from breaking, comprising an upper pot stand 1 in contact with pots and a lower pot stand 2 supporting the upper pot stand 1, and the lower pot stand 2 includes a spacer ring 2-1, a bottom ring 2-2 and pot support feet 2-3, the spacer 2-1 is supported on the bottom ring 2-2 through four pot support legs 2-3, and the pot support legs 2-3 are welded on the bottom ring 2- 2; the upper pot support 1 includes foot pieces 1-1, the upper pot support 1 is arranged on the spacer ring 2-1, and the upper pot support 1 is integrally cast and formed.

[0032] In this embodiment, the water receiving tray is arranged on the glass panel, and the bottom ring 2-2 of the lower pot support 2 is arranged above the water receiving tray. The upper pot support 1 is a ring-shaped structure, including the foot piece 1-1, the heat insulation plate 1-2 and the outer wall 1-3, and the inner ring of the heat insulation plate 1-2 is prov...

Embodiment 3

[0034] A gas cooker includes a glass panel and a water receiving tray arranged on the glass panel, and also includes a pot support for preventing the glass panel from breaking, and the pan support is arranged on the water receiving tray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com