Preparation method of a sandwich-shaped flexible temperature sensor

A temperature sensor and sandwich technology, applied to thermometers, thermometers, instruments, etc. that are directly sensitive to heat/magnetic elements, can solve the problem of increasing the electrostatic repulsion on the surface of particles, reducing the van der Waals force between graphene particles, and increasing graphene sheets Layer distance etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

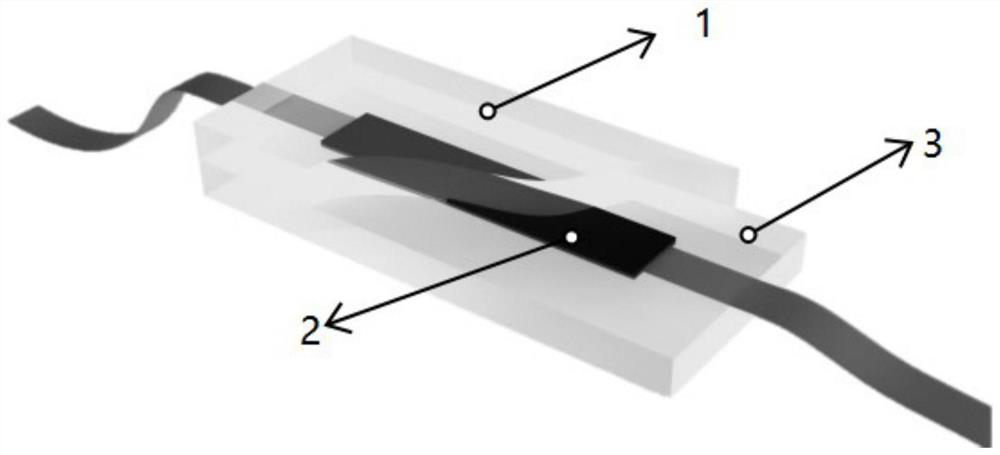

[0042] Such as figure 1 As shown, the present invention discloses a sandwich-shaped flexible temperature sensor, which includes an upper substrate 1 and a lower substrate 3 that are arranged up and down, and a strip-shaped sensor that is arranged in the bonding surface between the upper substrate 1 and the lower substrate 3 Conductive layer 2, and two conductive adhesive tapes that are respectively connected to the two ends of the conductive layer 2 and protrude from the bonding surface;

[0043] The upper substrate 1 and the lower substrate 3 are prepared from PDMS monomer and curing agent;

[0044] The conductive layer 2 is prepared from a graphene dispersion.

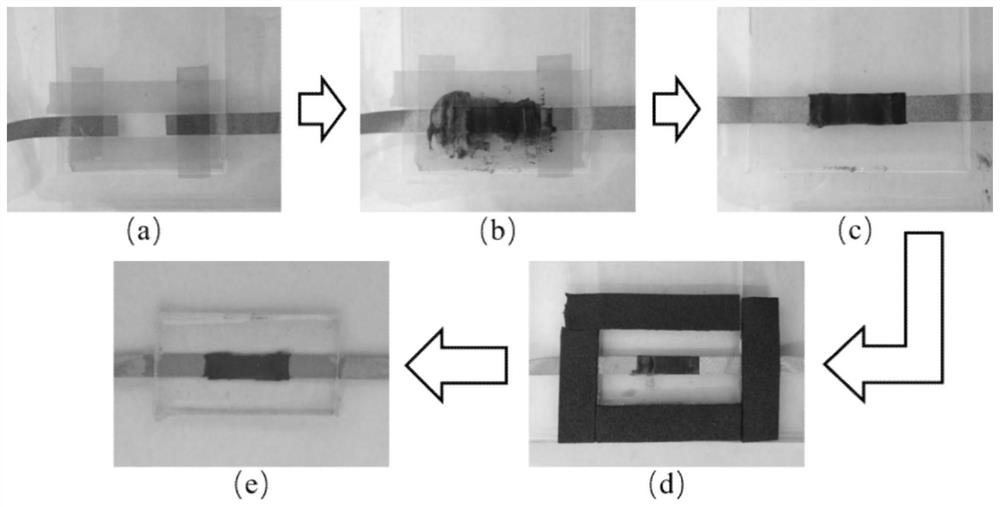

[0045] In addition, this embodiment 1 discloses a method for preparing the sandwich-shaped flexible temperature sensor, which specifically includes the following steps:

[0046] Prepare a PDMS curing solution, and inject the PDMS curing solution into the first groove mold, and obtain the lower substrate 3 after cur...

Embodiment 2

[0052] This embodiment is an extended embodiment of the first embodiment, and its difference from the first embodiment is that the preparation of the upper and lower substrates and the preparation of the conductive layer are refined, and the performance of the prepared flexible sensor is tested. Specifically:

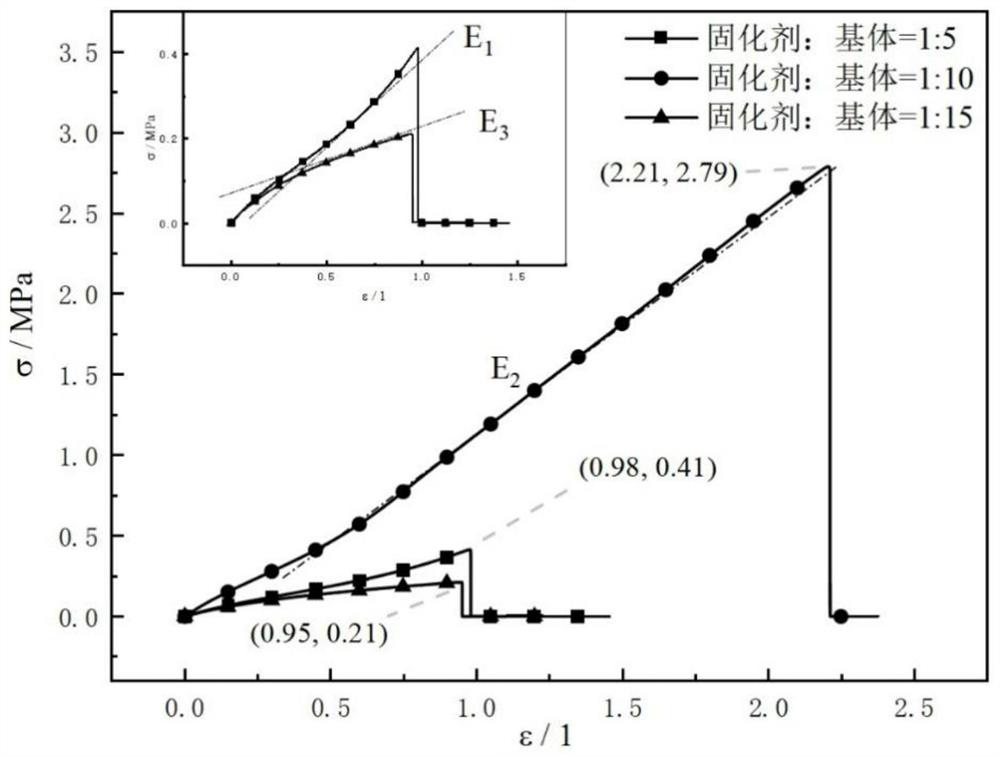

[0053] Preparation of upper and lower substrates

[0054] As a flexible temperature sensor used in the wearable field, the "sandwich structure" requires its substrate to have excellent flexibility. PDMS has the advantages of wide temperature range, good biocompatibility and low preparation cost. Therefore, in this experiment, PDMS was selected as the upper and lower substrates of the "sandwich", and a sandwich-shaped flexible temperature sensor was designed and manufactured. The preparation of PDMS is obtained by mixing monomers and curing agents according to a certain ratio, and curing conditions at a certain temperature and time to finally obtain PDMS flexible mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com