Welding pool microstructure evolution simulation method based on cellular automaton method

A technology of welding molten pool and cellular automation, which is applied in the fields of instrumentation, calculation, and electrical digital data processing, etc., can solve the problems of large amount of calculation and low calculation efficiency of microstructure evolution, and achieve improved welding quality, low cost and long research cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

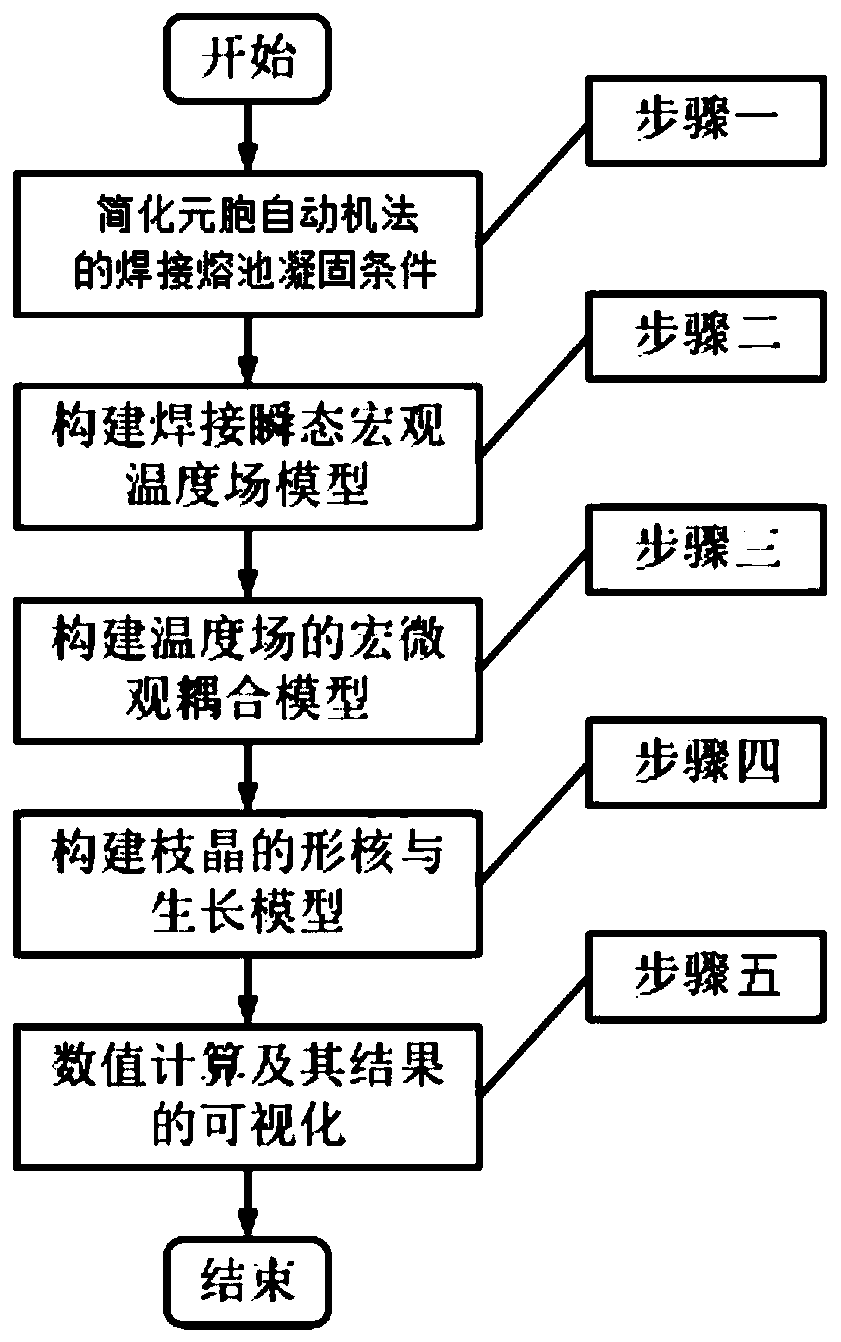

[0085] A simulation method based on the cellular automata method for the microstructure evolution of the weld pool, such as figure 1 As shown, the specific steps are as follows:

[0086] 1. A method for simulating the evolution of weld pool microstructure based on cellular automata, characterized in that, it is specifically implemented according to the following steps:

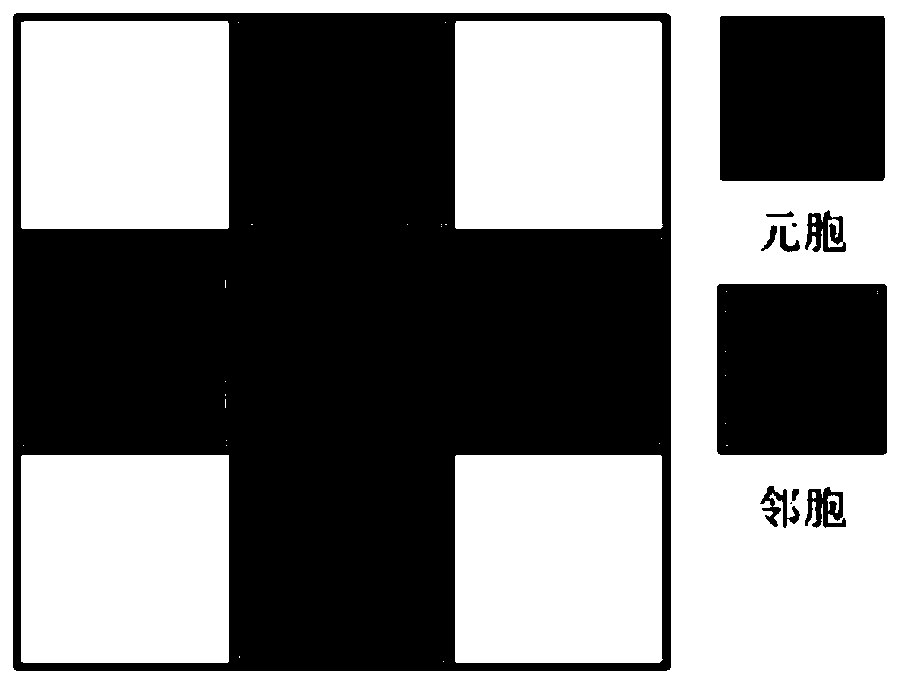

[0087] Step 1, simplifying the welding pool solidification condition of the cellular automata method;

[0088] Step 2. Based on the heat transfer theory, construct a transient macroscopic temperature field model during the welding process;

[0089] Step 3. Based on the principle of interpolation, transform the macroscopic welding temperature field into a macroscopic and microcosmic coupling model of the microscopic temperature field required for microstructure evolution;

[0090] Step 4. On the premise of obtaining the microscopic temperature field, construct a nucleation and growth model of dendrites under ...

Embodiment 2

[0152] A simulation method based on the cellular automata method for the microstructure evolution of the weld pool, such as figure 1 As shown, the specific steps are as follows:

[0153] Step 1, simplifying the welding pool solidification condition of the cellular automata method;

[0154] Step 2. Based on the heat transfer theory, construct a transient macroscopic temperature field model during the welding process;

[0155] Step 3. Based on the principle of interpolation, transform the macroscopic welding temperature field into a macroscopic and microcosmic coupling model of the microscopic temperature field required for microstructure evolution;

[0156] Step 4. On the premise of obtaining the microscopic temperature field, construct a nucleation and growth model of dendrites under transient conditions based on grain nucleation and growth;

[0157] Step 5. Calculation and visualization of its results.

[0158] 2. a kind of welding pool microstructure evolution simulation ...

Embodiment 3

[0218] A simulation method based on the cellular automata method for the microstructure evolution of the weld pool, such as figure 1 As shown, the specific steps are as follows:

[0219] 1. A method for simulating the microstructure evolution of the weld pool based on the cellular automata method, specifically implemented according to the following steps:

[0220] Step 1, simplifying the welding pool solidification condition of the cellular automata method;

[0221] Step 2. Based on the heat transfer theory, construct a transient macroscopic temperature field model during the welding process;

[0222] Step 3. Based on the principle of interpolation, transform the macroscopic welding temperature field into a macroscopic and microcosmic coupling model of the microscopic temperature field required for microstructure evolution;

[0223] Step 4. On the premise of obtaining the microscopic temperature field, construct a nucleation and growth model of dendrites under transient cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com