Method for screening sensitive variables influencing product quality in complex industrial process based on step-by-step reduction

A technology for product quality and industrial process, applied in the field of soft sensing, which can solve the problems of reducing the accuracy of prediction models, not having the ability to describe information about process conditions, and easily ignoring the correlation of variables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

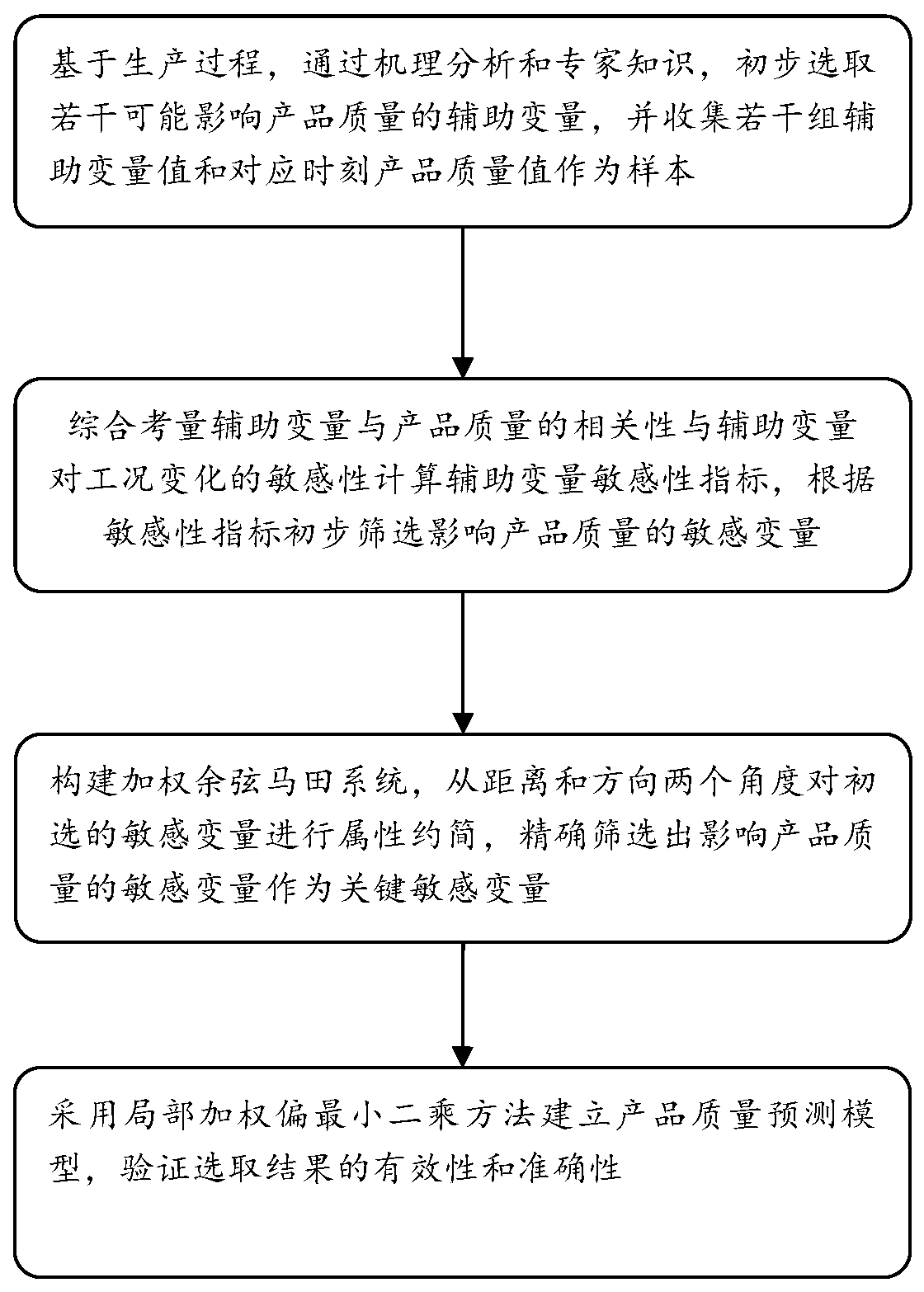

[0141] The application of the technical solution disclosed in the present invention to the product quality prediction of the hydrocracking process includes the following steps:

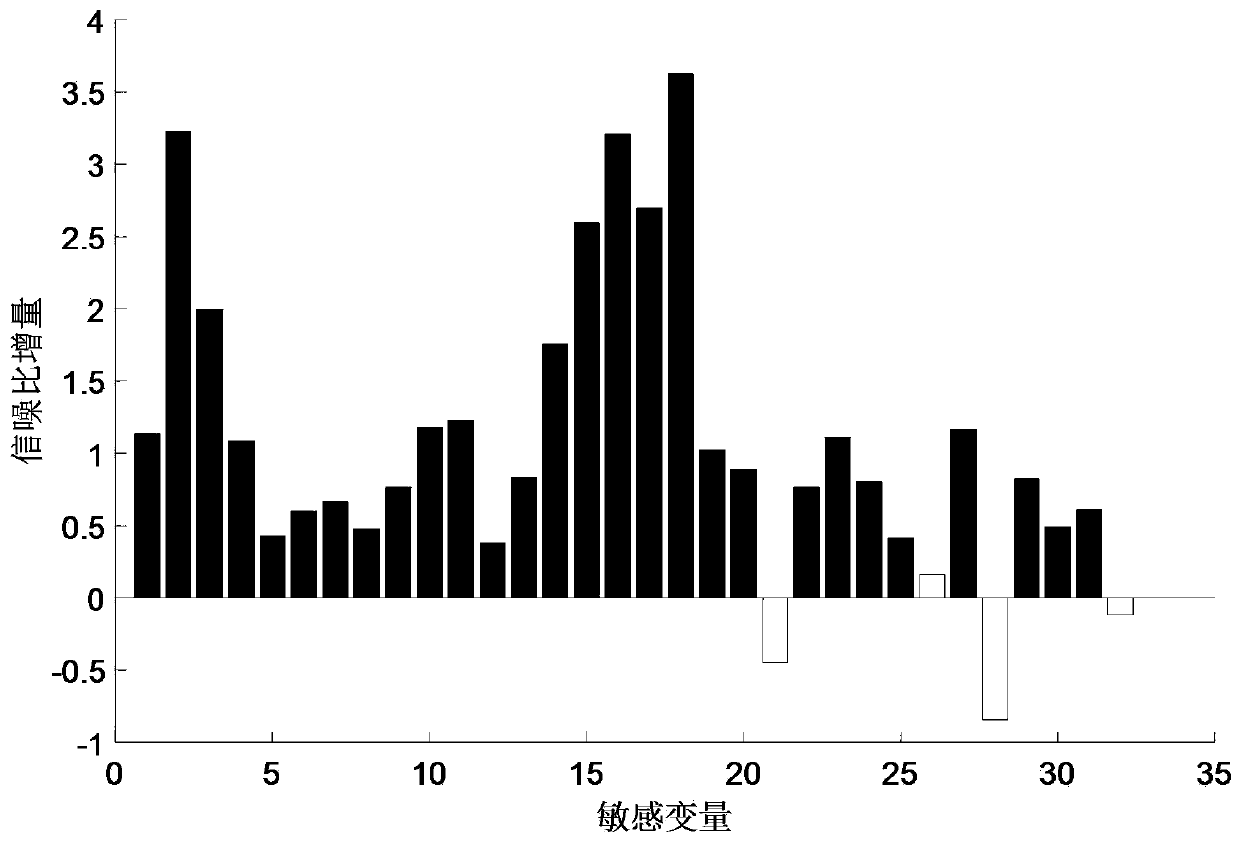

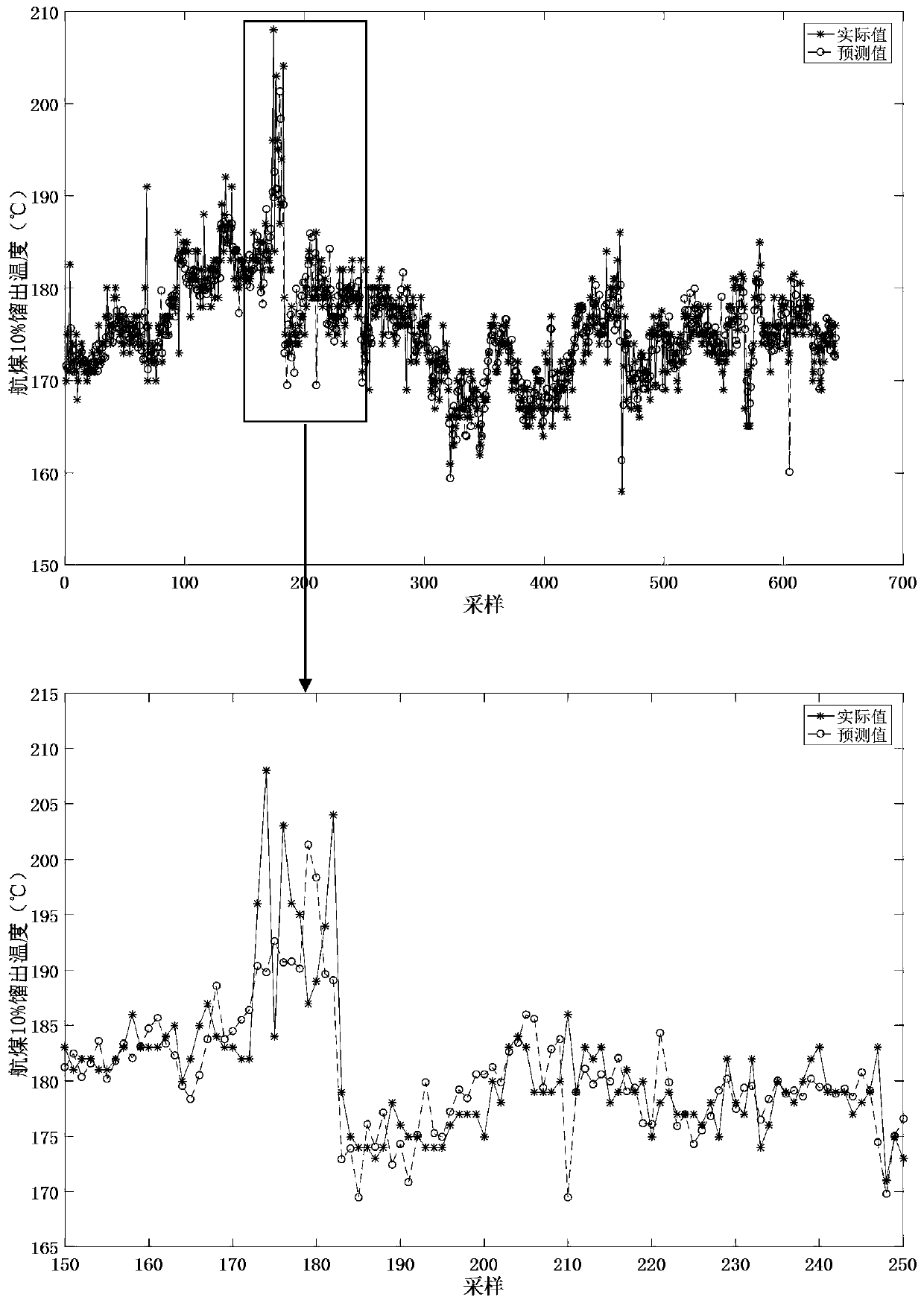

[0142] a. Based on the cracking production process, according to the mechanism analysis and expert experience, a total of 39 relevant variables that have an impact on the quality index of the 10% distillate temperature of jet fuel are initially selected as input variables for the quality prediction of the hydrocracking process, which are respectively recorded as x 1 、x 2 ,...,x 39 , Extracted 966 days of continuous production, sampling data of 39 related variables, extracted 966 days of 10% distillation temperature data of aviation fuel measured off-line at 8 o'clock and 20 o'clock every day, a total of 1932 groups. The obtained data are divided into two parts for prediction and modeling of jet fuel 10% distillate temperature quality index based on LWPLS, among which 1288 groups are used as training...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com