Hub deburring device

A deburring and wheel hub technology, which is applied in the field of wheel hub manufacturing, can solve the problems of automatic removal of pouring lugs, inability to polish wheel hub burrs, and incomplete polishing, and achieves the effects of reducing manpower, small size, and improving accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

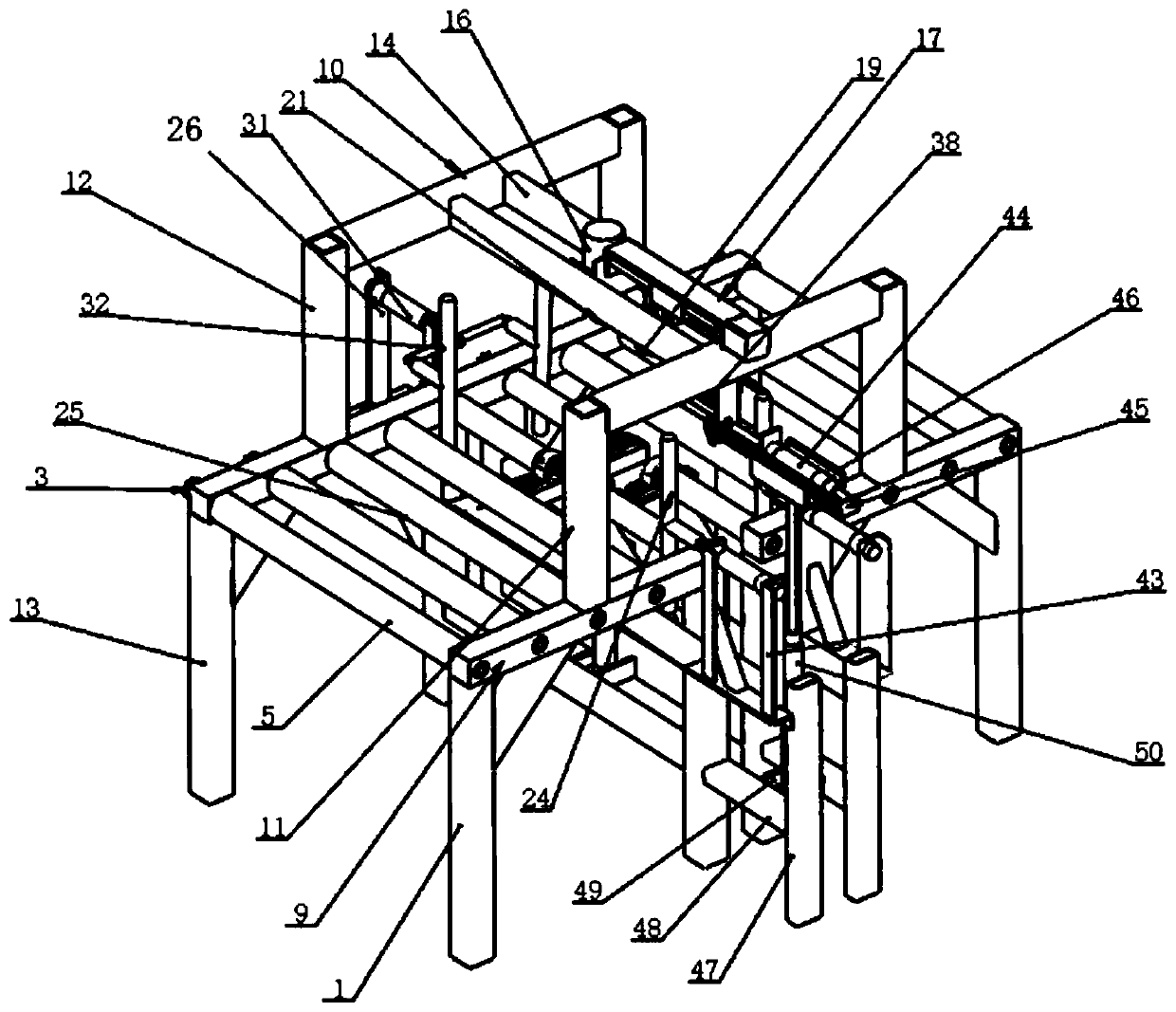

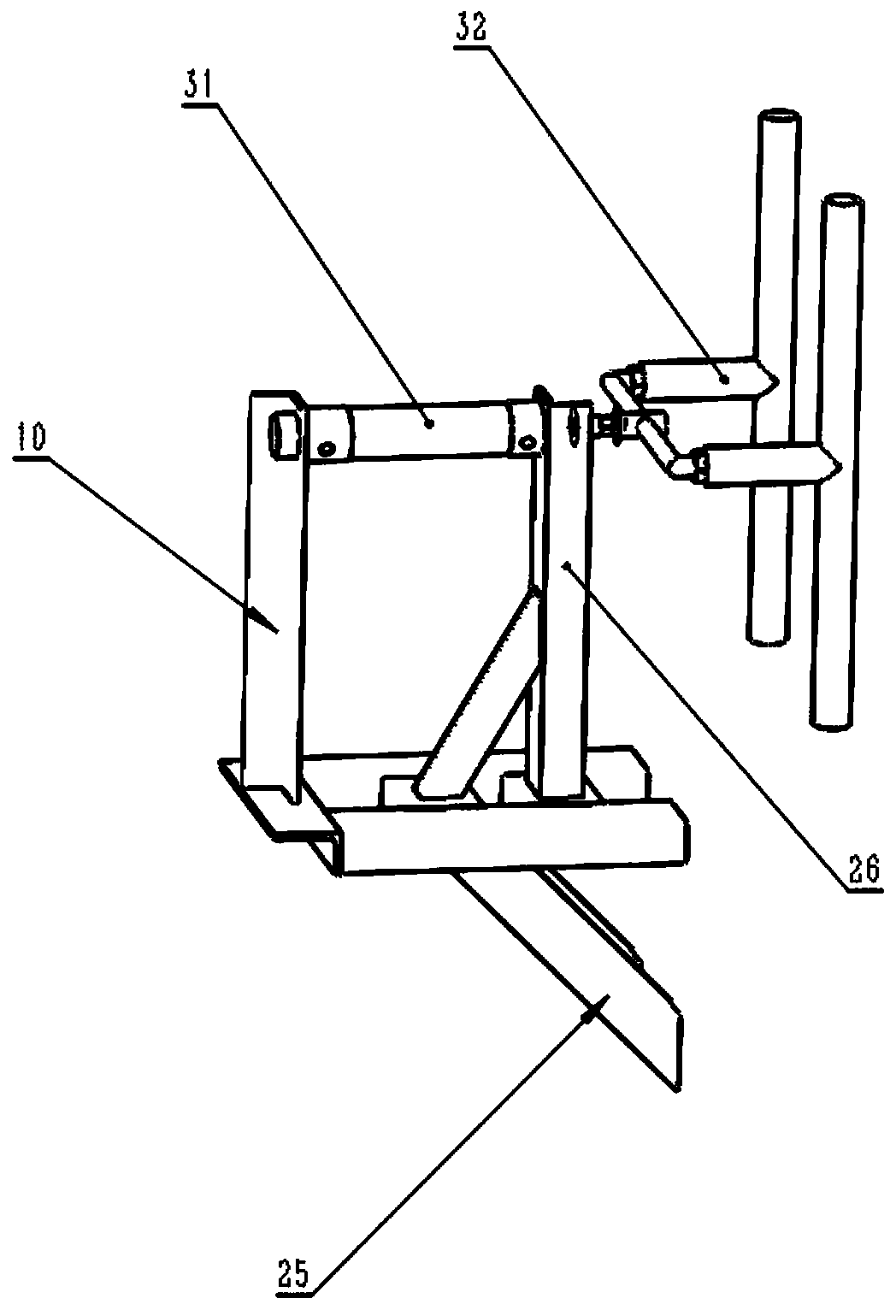

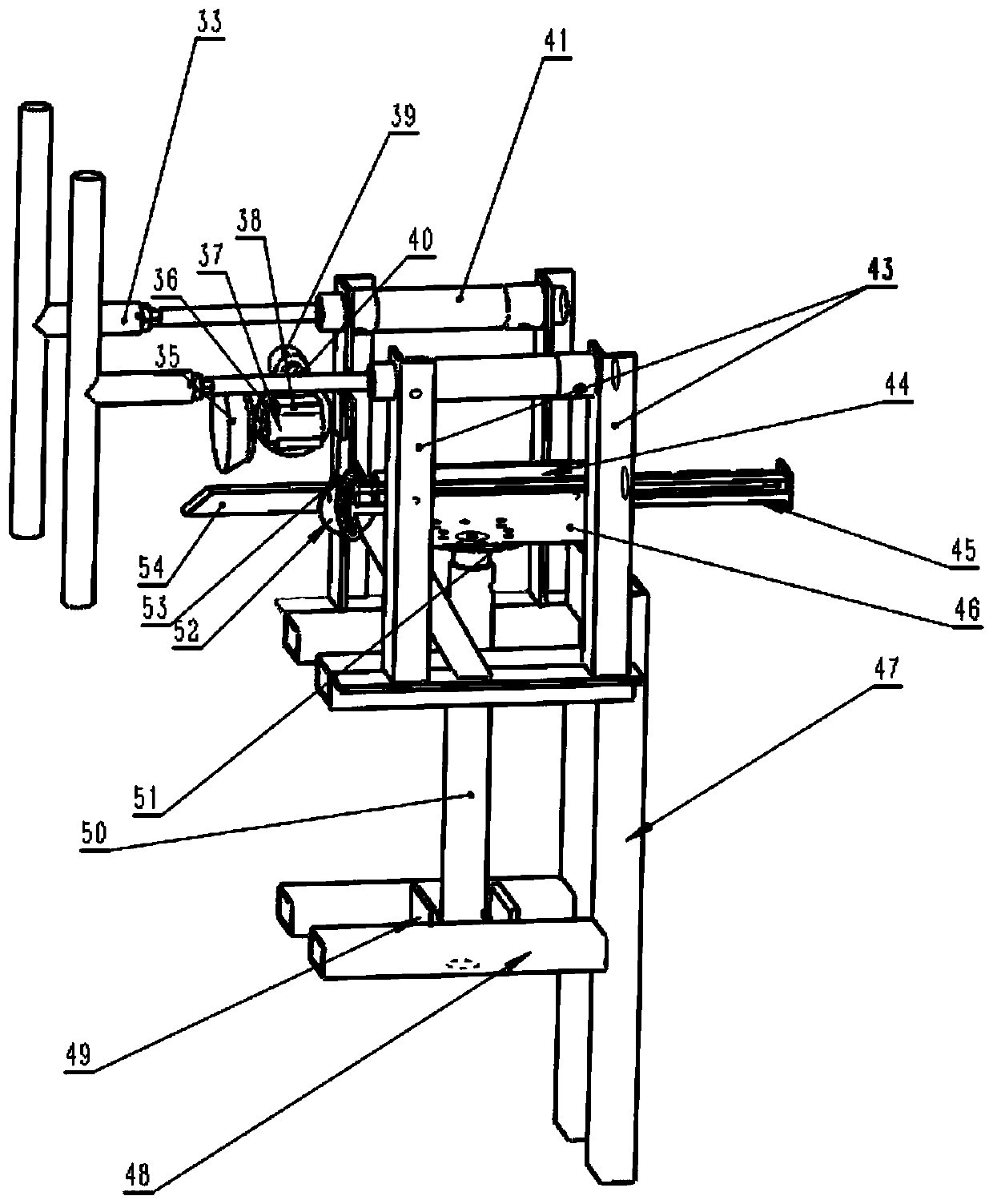

[0037] Such as Figure 1-5 As shown, the embodiment of the present invention provides a hub deburring device, which includes a support base 13 , support legs 1 are provided on both sides below the support base 13 , and a support block 9 is provided at the top of the support legs 1 .

[0038] One end of the support block 9 is provided with a first drive roller 4, and one end of the first drive roller 4 is provided with a bearing 6, and the bottom end of the bearing 6 is provided with a support plate 7, and the bottom end of the support plate 7 is provided with a support rod 8, and supports The other end of the rod 8 is connected with the support leg 1 .

[0039] Both sides of the first transmission roller 4 are all provided with the second transmission roller 5, and the second transmission roller 5 is connected with the support block 9, as Figure 5 As shown, the length of the first transmission roller 4 is shorter than the second transmission roller 5, and one end of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com