Drinks filling device

A filling device, wine technology, applied in the safety device, packaging, bottle filling and other directions of the filling device, can solve the problems of high cost, easy damage and complex structure of the solenoid valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

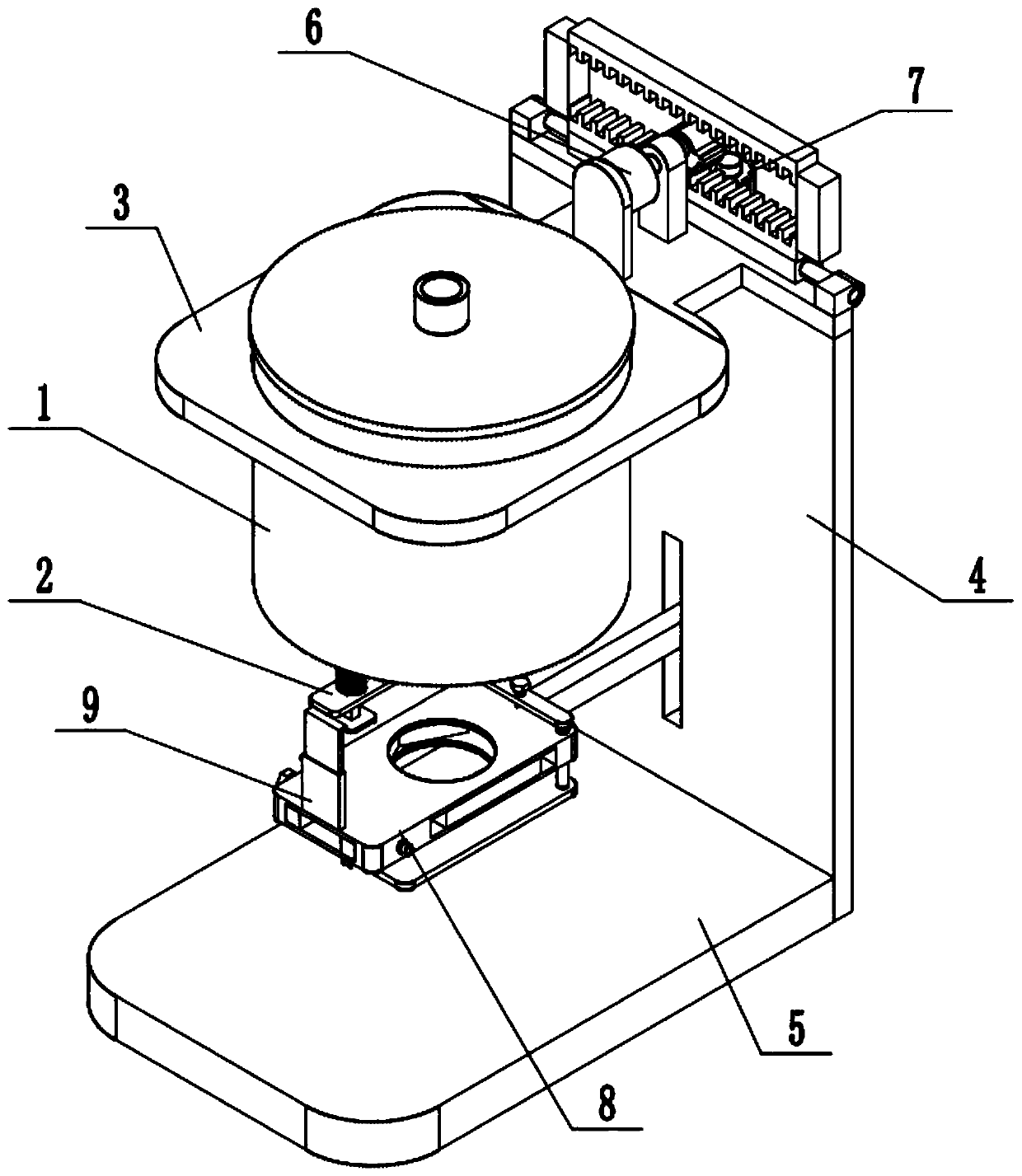

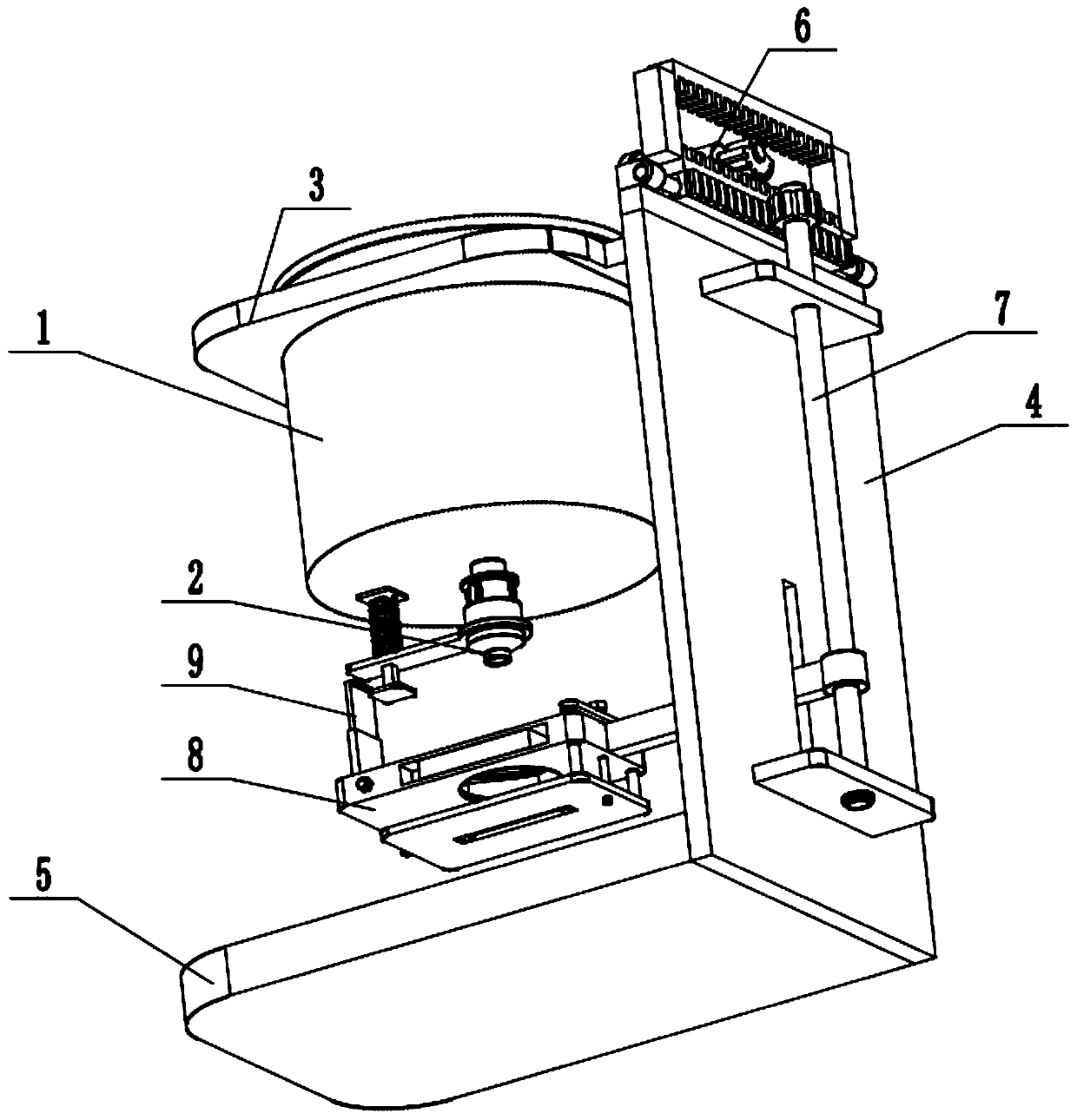

[0033] Such as Figure 1-13As shown, a wine filling device includes a wine storage barrel 1, a filling head 2, a barrel fixing seat 3, a stand 4, a base 5, a filling control mechanism 6, a lifting mechanism 7, a wine bottle seat 8 and a top pressure plate 9. The lower end of the wine storage barrel 1 is fixedly connected with the filling head 2; the wine storage barrel 1 is fixed on the barrel fixing seat 3; the barrel fixing seat 3 is fixed on the stand 4; the stand 4 fixed on the base 5; the filling control mechanism 6 is fixed on the bucket fixing seat 3; the filling control mechanism 6 is connected to the lifting mechanism 7; the lifting mechanism 7 is connected to the stand 4; the lifting mechanism 7 is connected to the wine bottle seat 8 by transmission; the wine bottle seat 8 is slidingly fitted on the stand 4; the top pressure plate 9 is fixedly connected to the wine bottle seat 8; the top pressure plate 9 is connected to the filling head 2 by transmission. A wine fil...

Embodiment 2

[0035] Such as Figure 1-13 As shown, the upper end of the wine storage barrel 1 is fixedly connected with a bung; the bung is provided with a wine inlet pipe with a control valve. The setting of the wine inlet pipe is used to load wine, and the wine can be stored through the wine storage barrel 1 .

Embodiment 3

[0037] Such as Figure 1-13 As shown, the filling head 2 includes a flow tube 201 with a closed bottom, a stepped flow control tube 202, a filling tube 203, a movable platen 204, a compression spring 205, a rectangular slide bar 206 and a slide bar seat 207; the flow tube The upper end of 201 is fixedly connected with the wine storage barrel 1; the lower end of the circulation pipe 201 is in sealing and sliding fit with the upper end of the stepped flow control pipe 202; the lower end of the stepped flow control pipe 202 is fixedly connected with the filling pipe 203 The lower end of the pipe body of the flow pipe 201 is evenly surrounded by a plurality of flow holes; one end of the movable platen 204 is fixed on the stepped flow control pipe 202, and the other end of the movable platen 204 is slidably fitted on the rectangular slide bar 206; The upper and lower ends of the rectangular slide bar 206 are respectively fixedly connected with a slide bar seat 207, and the slide ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com