A kind of processing method of arsenic slag

A treatment method and technology of arsenic slag, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of increasing disposal links, affecting the stability of curing/stabilizing conditions, and the inconsistency between oxidant products and curing agents Compatibility and other issues to achieve the effect of maintaining stability and reducing the concentration of leaching toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

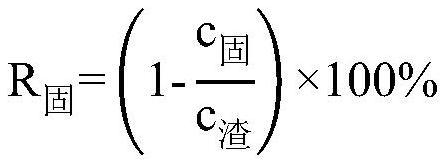

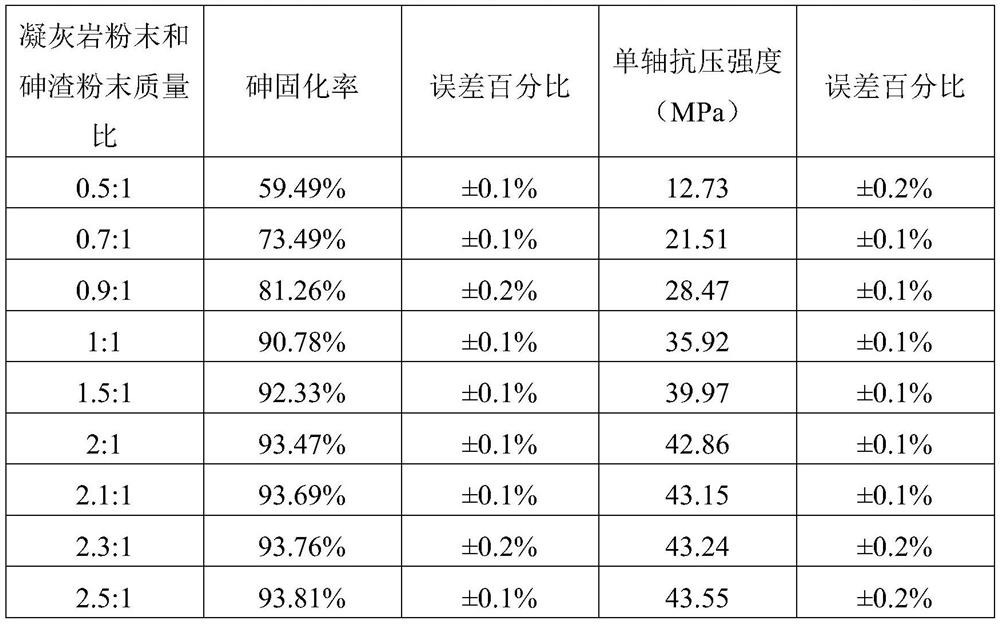

[0018] Effects of the mass ratio of tuff powder and arsenic slag powder on the arsenic solidification rate and uniaxial compressive strength of arsenic slag gel solidified body

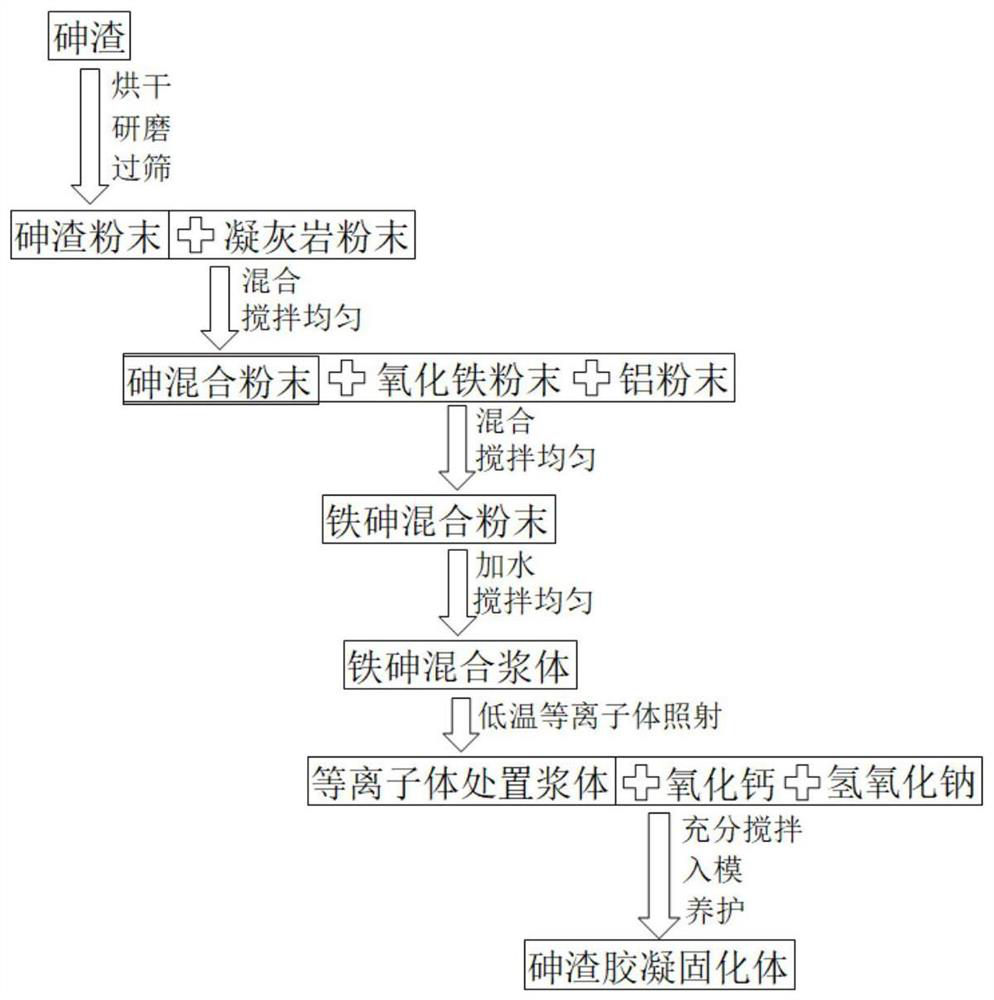

[0019] Such as figure 1 As shown, the arsenic slag was dried, ground, and passed through a 200-mesh sieve to obtain arsenic slag powder. According to the mass ratio of 5:3:100, calcium oxide, sodium hydroxide, and tuff powder were weighed respectively; according to the mass ratio of 0.5:1, 0.7:1, 0.9:1, 1:1, 1.5:1, 2:1, 2.1:1, 2.3:1, 2.5:1 respectively weigh tuff powder and arsenic slag powder, mix and stir evenly to get arsenic mixed powder ; According to mass ratio 5:5:100, take iron oxide powder, aluminum powder, arsenic mixed powder respectively, mix, stir uniformly, obtain iron-arsenic mixed powder; According to liquid-solid ratio 55:100 (mL:mg), water and Mix the iron-arsenic mixed powder and stir evenly to obtain the iron-arsenic mixed slurry; perform low-temperature plasma irradiation on the ...

Embodiment 2

[0028] Effect of mass ratio of iron oxide powder, aluminum powder and arsenic mixed powder on arsenic solidification rate and uniaxial compressive strength of arsenic slag gelled solidified body

[0029] Dry and grind the arsenic slag, pass through a 300-mesh sieve to obtain arsenic slag powder, weigh calcium oxide, sodium hydroxide, and tuff powder respectively according to the mass ratio of 7.5:4.5:100; weigh the tuff powder according to the mass ratio of 2:1 powder and arsenic slag powder, mix and stir evenly to obtain arsenic mixed powder; according to mass ratio 2.5:2.5:100, 3.5:3.5:100, 4.5:4.5:100, 5:2.5:100, 5:3.5:100, 5 :4.5:100, 2.5:5:100, 3.5:5:100, 4.5:5:100, 5:5:100, 5:7.5:100, 5:10:100, 7.5:5:100, 7.5:7.5 :100, 7.5:10:100, 10:5:100, 10:7.5:100, 10:10:100, 10:10.5:100, 10:11.5:100, 10:12.5:100, 10.5:10:100 , 11.5:10:100, 12.5:10:100, 10.5:10.5:100, 11.5:11.5:100, 12.5:12.5:100, respectively weigh iron oxide powder, aluminum powder, arsenic mixed powder, mix, stir...

Embodiment 3

[0035] Effects of mass ratio of calcium oxide, sodium hydroxide, and tuff powder on arsenic solidification rate and uniaxial compressive strength of arsenic slag gel solidification

[0036] Dry and grind the arsenic slag, pass through a 300-mesh sieve to obtain arsenic slag powder, according to the mass ratio of 2.5:1.5:100, 3.5:2:100, 4.5:2.5:100, 2.5:3:100, 3.5:3:100 , 4.5:3:100, 5:1.5:100, 5:2:100, 5:2.5:100, 5:3:100, 5:4.5:100, 5:6:100, 7.5:3:100, 7.5 :4.5:100, 7.5:6:100, 10:3:100, 10:4.5:100, 10:6:100, 10.5:6:100, 11.5:6:100, 12.5:6:100, 10:6.5 :100, 10:7:100, 10:7.5:100, 10.5:6.5:100, 11.5:7:100, 12.5:7.5:100, weigh calcium oxide, sodium hydroxide, tuff powder respectively; 1. Weigh tuff powder and arsenic slag powder respectively, mix and stir evenly to obtain arsenic mixed powder. According to the mass ratio of 10:10:100, weigh iron oxide powder, aluminum powder, and arsenic mixed powder respectively, mix and stir evenly to obtain iron-arsenic mixed powder; The arse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com