Polylactic acid/polycaprolactone-based elastomer blend and preparation method thereof

A technology of polycaprolactone and polylactic acid, which is applied in the field of polylactic acid/polycaprolactone-based elastomer blends and its preparation, can solve the problems of non-biodegradability and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. This embodiment provides a polylactic acid / polycaprolactone-based elastomer blend in parts by weight, comprising the following components: 100 parts of polylactic acid, 10 parts of polycaprolactone three with a molecular weight of 2000g / mol alcohol, and 3 parts of hexamethylene diisocyanate.

[0026] 2. The preparation method of the polylactic acid / polycaprolactone-based elastomer blend comprises the steps:

[0027] Step 1. Premix 100 parts of polylactic acid and 10 parts of polycaprolactone triol with a molecular weight of 2000 g / mol in an internal mixer for 5 minutes, and the blending temperature is 180° C.

[0028] Step 2. Add hexamethylene diisocyanate to the blending system. The molar ratio of hexamethylene diisocyanate to the isocyanate group of the hydroxyl group of polycaprolactone triol is 1:1.15, and continue at 180°C After reacting for 8 minutes, the polylactic acid / polycaprolactone-based elastomer blend was obtained.

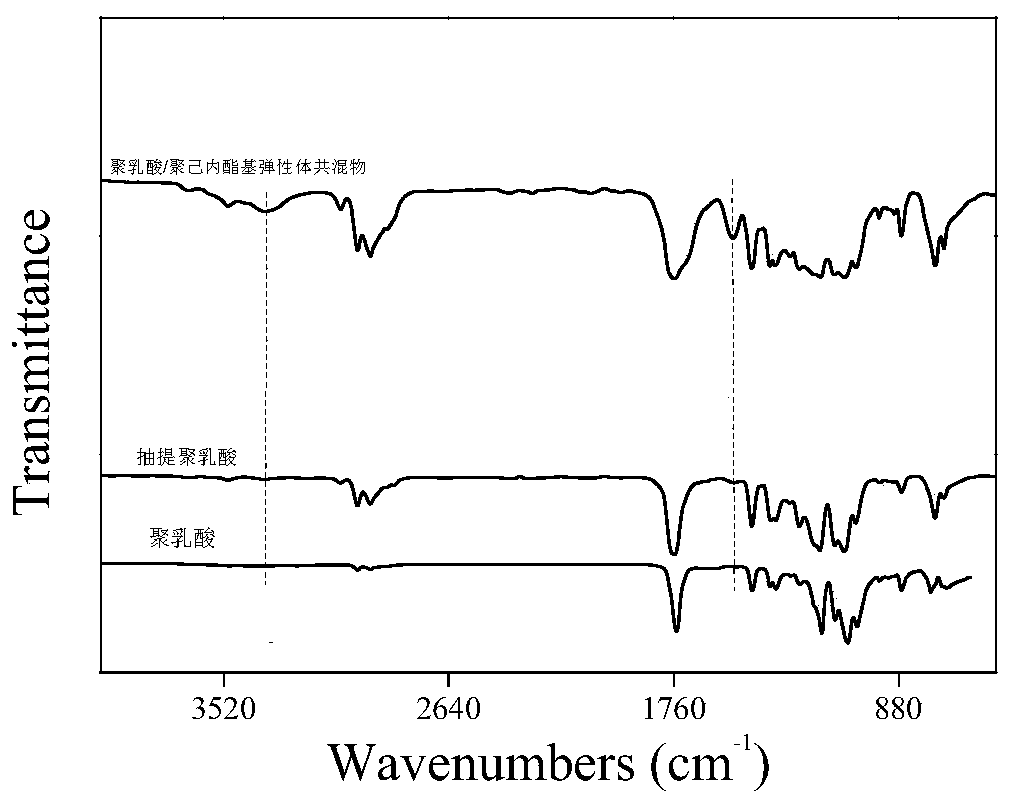

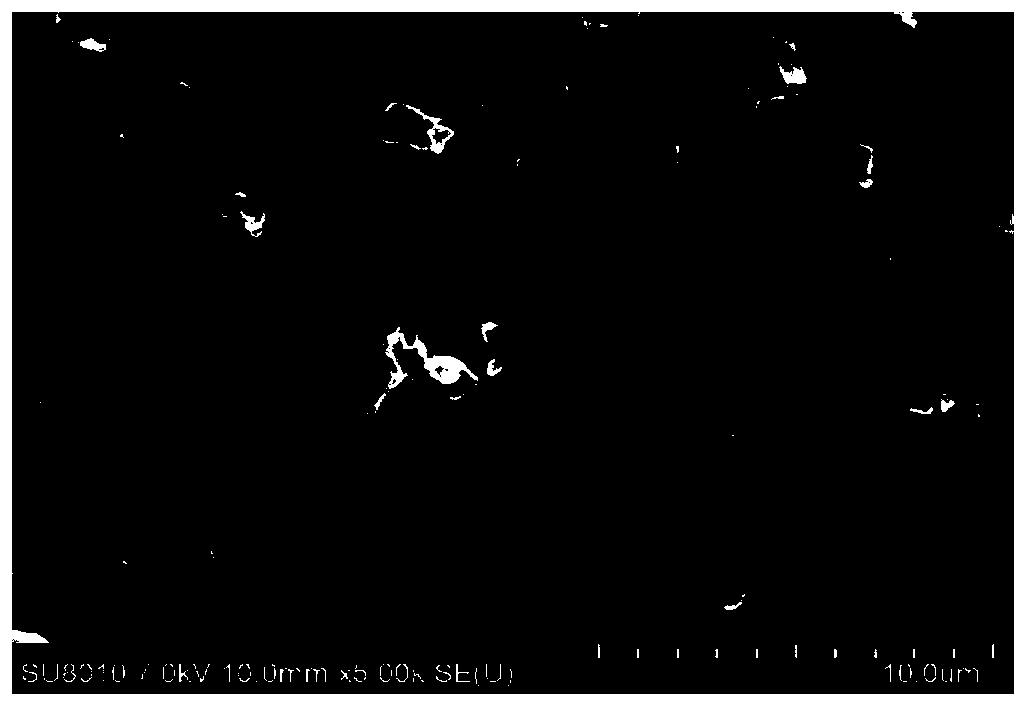

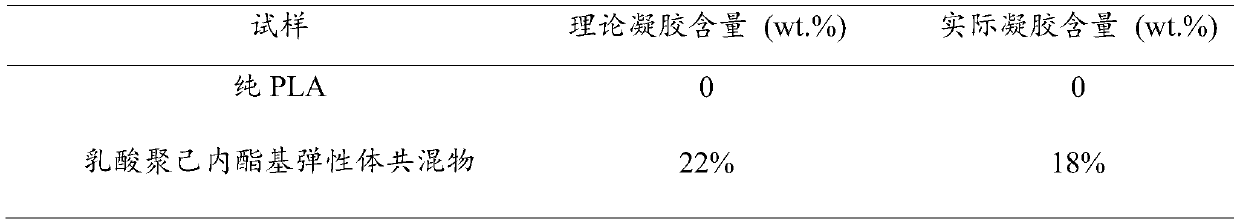

[0029] 3. Properties of polylactic...

Embodiment 2

[0033] 1. This embodiment provides a polylactic acid / polycaprolactone-based elastomer blend in parts by weight, which includes the following components: 100 parts of polylactic acid, 20 parts of polycaprolactone with a molecular weight of 4000g / mol Alcohol, 5 parts polyphenyl polymethylene polyisocyanate.

[0034] 2. The preparation method of the polylactic acid / polycaprolactone-based elastomer blend comprises the steps:

[0035] Step 1. Premix 100 parts of polylactic acid and 20 parts of polycaprolactone diol with a molecular weight of 4000 g / mol in an internal mixer for 5 minutes, and the blending temperature is 190° C.

[0036] Step 2. Add polyphenyl polymethylene polyisocyanate to the blending system. The molar ratio of polyphenyl polymethylene polyisocyanate according to the hydroxyl group and isocyanate group of polycaprolactone diol is 1:1.05 , Continue the reaction at 190° C. for 8 minutes to obtain a polylactic acid / polycaprolactone-based elastomer blend.

[0037] 3...

Embodiment 3

[0041]1. This embodiment provides a polylactic acid / polycaprolactone-based elastomer blend in parts by weight, comprising the following components: 100 parts of polylactic acid, 15 parts of polycaprolactone three with a molecular weight of 6000g / mol Basic acid, 10 parts styrene-glycidyl methacrylate copolymer.

[0042] 2. The preparation method of the polylactic acid / polycaprolactone-based elastomer blend comprises the steps:

[0043] Step 1. Premix 100 parts of polylactic acid and 15 parts of polycaprolactone tribasic acid with a molecular weight of 6000 g / mol in an internal mixer for 4 minutes, and the blending temperature is 200° C.

[0044] Step 2, add styrene-glycidyl methacrylate copolymer to the blend system, the styrene-glycidyl methacrylate copolymer is based on the carboxyl group and epoxy group mole of polycaprolactone tribasic acid The ratio is 1:1.5, and the reaction is continued at 200°C for 10 minutes to obtain a polylactic acid / polycaprolactone-based elastomer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com