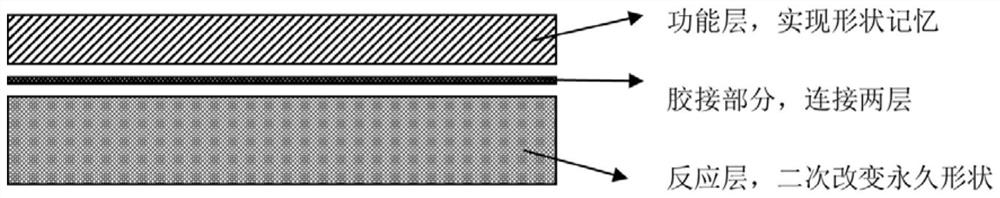

Method for preparing shape memory polymer device with complex permanent shape by utilizing secondary crosslinking and application of shape memory polymer device

A polymer device and secondary cross-linking technology, applied in prosthetics, medical science, etc., can solve the problems of increasing material processing costs, permanent shape can no longer be changed, and reducing the complexity of permanent shape of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (polyurethane-acrylate secondary crosslinking reaction system)

[0034] The raw material of embodiment 1 and source are as shown in table 1:

[0035] Table 1. Embodiment 1 raw material and source thereof

[0036]

[0037] Polymer Network Synthesis:

[0038] Mix HDI, PTMG, HEA, and Gly in DMF at a ratio of isocyanate to hydroxyl molar ratio of 1.05:1, where the ratio of PTMG, HEA, and Gly will determine the final properties of the material (such as the shape memory temperature of the material, etc.) , can be adjusted according to actual needs. After the above substances are mixed evenly, 1 wt% of DBTDL is added into the system as a polymerization catalyst, and 1 wt% of trimethylbenzoyl-diphenylphosphorus oxide is added as a photoinitiator under the condition of avoiding light. The obtained mixture was poured into a mold, cured at 70°C for 12 hours, post-cured at 120°C for 2 hours, and DMF was removed in a vacuum oven to obtain the desired polymer film....

Embodiment 2

[0041] Embodiment 2 (epoxy-acrylate secondary crosslinking reaction system)

[0042] The raw material of embodiment 2 and source are as shown in table 2:

[0043] Table 2. Embodiment 2 raw materials and sources thereof

[0044]

[0045] Polymer Network Synthesis:

[0046]Mix E44, D230, and GMA at a ratio of 2:1 between epoxy groups and primary amino groups. The ratio of E44, D230 and GMA will affect the performance of the final material, and the ratio can be adjusted according to actual needs. After the above-mentioned substances are mixed evenly, 1 wt% of trimethylbenzoyl-diphenylphosphorus oxide is added into the system as a photoinitiator. The resulting mixture was poured into a mold, cured in an oven at 70°C for 12 hours, and post-cured in an oven at 120°C for 2 hours to obtain the desired polymer film.

[0047] polymer network

[0048] The synthesized polymer film deforms under stress (such as being pressed and deformed when attached to the surface of an object), ...

Embodiment 3

[0049] Embodiment 3 (polyurethane-cycloaddition secondary crosslinking reaction system)

[0050] The raw material of embodiment 3 and source are as shown in table 3:

[0051] Table 3. Embodiment 3 raw materials and sources thereof

[0052]

[0053]

[0054] Polymer Network Synthesis:

[0055] Mix HDI, PTMG, HEA, and DAME in DMF at a ratio of isocyanate to hydroxyl molar ratio of 1.05:1, where the ratio of PTMG, HEA, and DAME will determine the final performance of the material (such as the shape memory temperature of the material, etc.) , can be adjusted according to actual needs. After the above substances are mixed evenly, 1 wt% of DBTDL is added into the system as a polymerization catalyst, and 1 wt% of trimethylbenzoyl-diphenylphosphorus oxide is added as a photoinitiator under the condition of avoiding light. The obtained mixture was poured into a mold, cured at 70°C for 12 hours, post-cured at 120°C for 2 hours, and DMF was removed in a vacuum oven to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com