Impermeable generator room cover

A nacelle cover and hatch door technology, which is applied in the field of anti-seepage nacelle cover, can solve the problems of generator nacelle cover sealing structure invalidation and running water infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

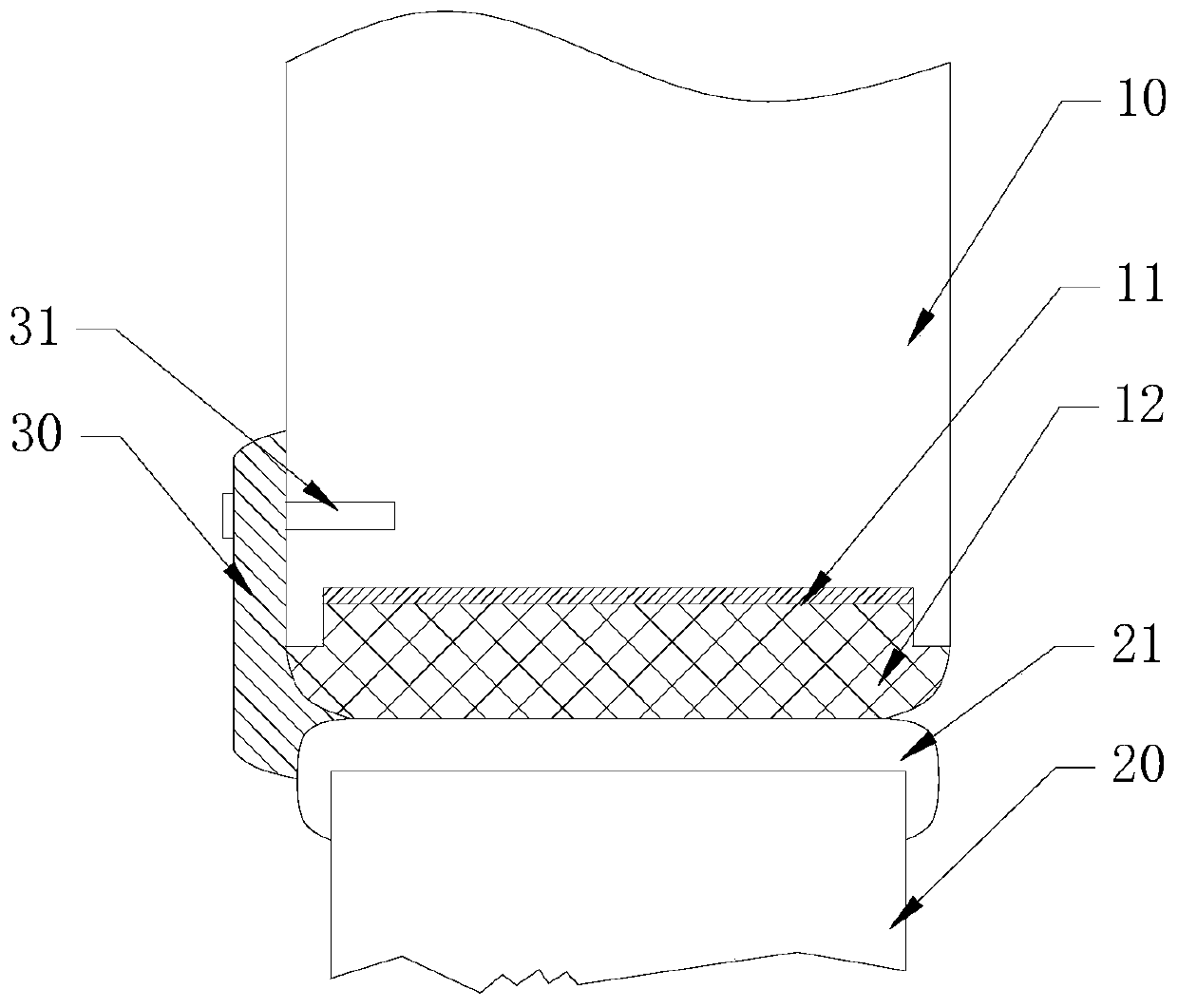

[0024] An anti-seepage nacelle cover provided in this embodiment includes a nacelle body 10 and at least one door panel 20 arranged on the nacelle body 10 , a seal is provided between the top of the door panel 20 and the nacelle body 10 . device, the sealing device includes a cabin sealing strip 12 and a hatch sealing strip 21, the cabin sealing strip 12 is arranged in the bonding groove 11 at the bottom of the nacelle cover body 10, and the hatch sealing strip 21 is arranged on the hatch panel 20 top;

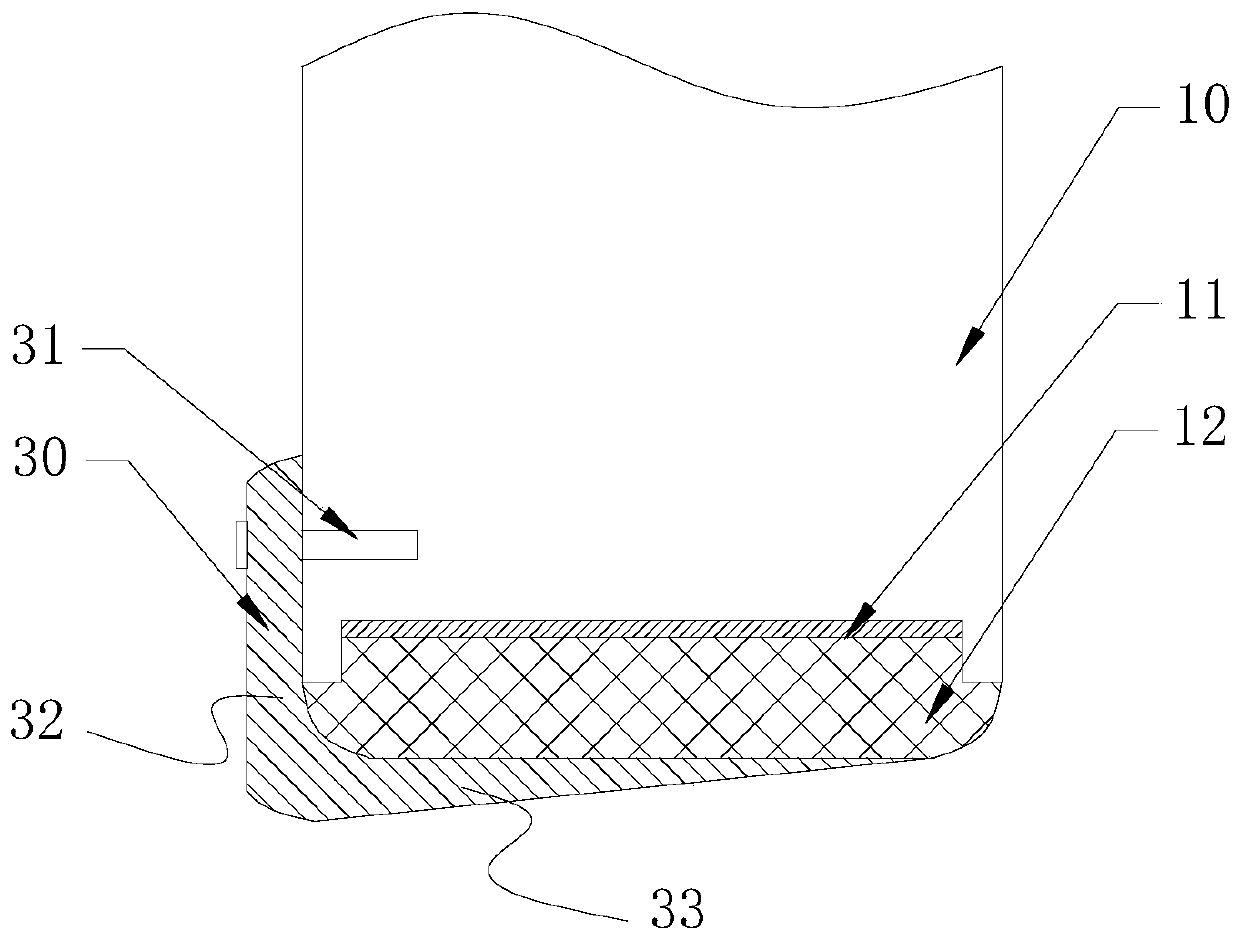

[0025] It also includes an inner seal 30, which includes a seal portion 32 and a wedge-shaped bottom 33;

[0026] The seal part 32 is installed on the inner wall of the nacelle cover body 10 through a plurality of fixing bolts 31;

[0027] The upper surface of the wedge-shaped bottom 33 is attached to the bottom of the cabin sealing strip 12 , the lower surface of the wedge-shaped bottom 33 is an inclined surface, and the wedge-shaped bottom 33 is a cushion with variable elas...

Embodiment 2

[0030] An anti-seepage nacelle cover provided in this embodiment includes a nacelle body 10 and at least one door panel 20 arranged on the nacelle body 10 , a seal is provided between the top of the door panel 20 and the nacelle body 10 . device, the sealing device includes a cabin sealing strip 12 and a door sealing strip 21, the cabin sealing strip 12 is arranged in the bonding groove 11 at the bottom of the nacelle cover body 10, the cabin sealing strip 12 is a rubber strip, and the cabin The bonding groove 11 of the cover body 10 is an inner groove, the bottom of the bonding groove 11 of the nacelle cover body 10 is provided with an anti-skid plate, the surface of the anti-skid plate is a matte surface for increasing friction, and the door sealing strip 21 is arranged on the cabin The top of the door panel body 20, the hatch door sealing strip 21 is covered and arranged on the top of the hatch panel body 20, and the hatch door sealing strip 21 is a rubber strip;

[0031] I...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap