Permanently-tight interlocked non-return nut

A nut and locking technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of impossibility and repeated use, and achieve the effect of reliable performance, wide application and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

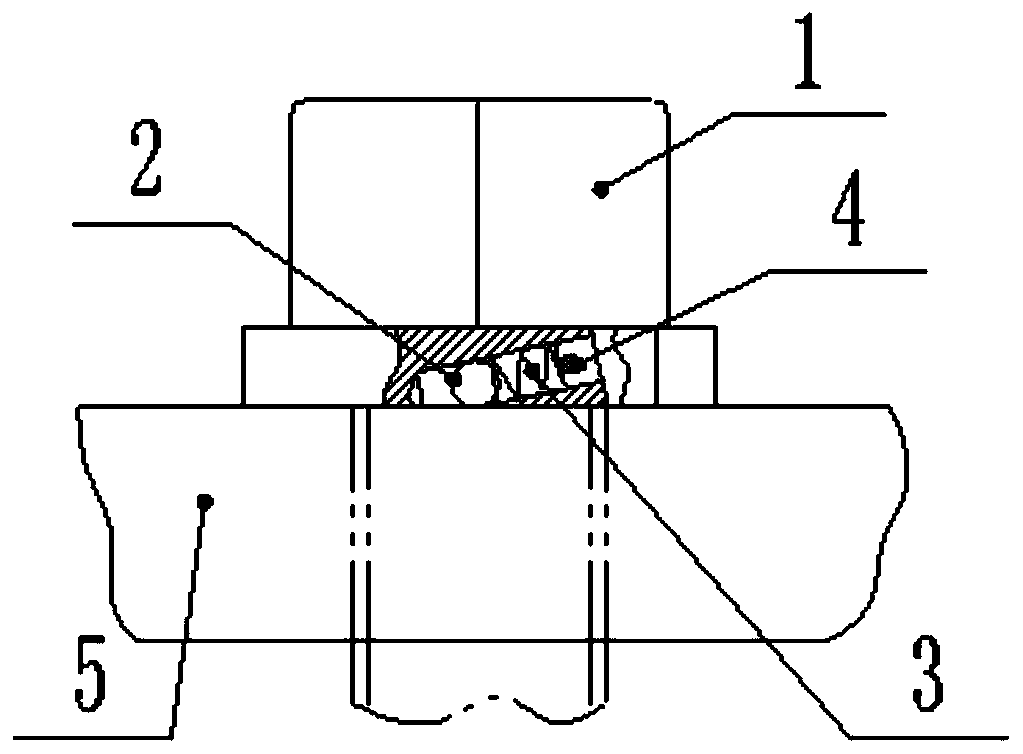

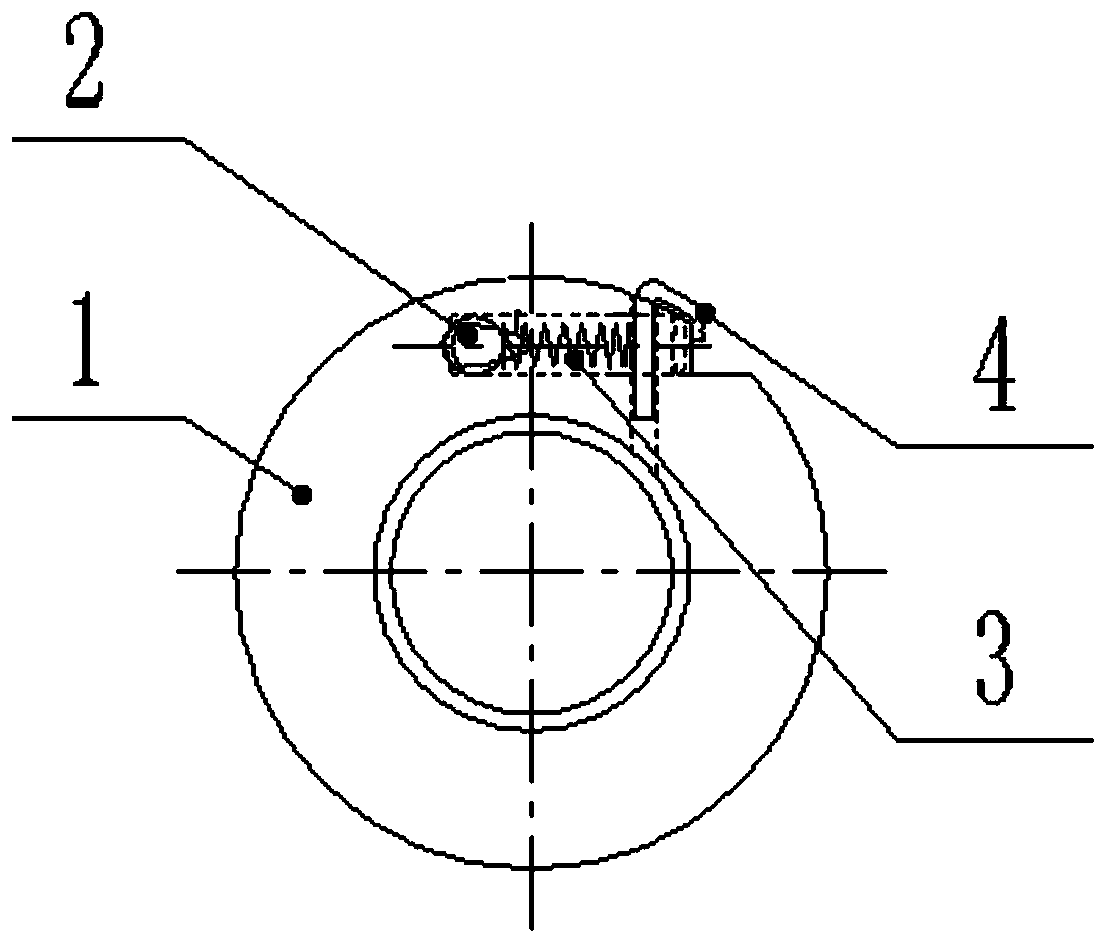

[0022] This embodiment is a plane interlocking non-return nut, such as figure 1 and 2 As shown: a spring hole is obliquely opened on the upper end surface of the lower end of the nut 1. The spring hole is an oblique hole. The oblique hole is perpendicular to the diameter. The apex of the oblique angle is the direction of rotation of the nut; the rolling body 2 and spring 3 are placed in the spring hole, the spring 3 is a compressed spring, the rolling body part protrudes from the lower end surface of the nut, and the upper end of the spring hole is provided with a lock pin hole, which is inserted Self-locking locking pin 4, rolling body is connected with locking pin by spring.

[0023] According to torque requirements, the number of spring holes on the nut is generally 1-12.

[0024] When working, when the nut 1 is screwed to the plane contact with the fastened part 5, the rolling body 2 is squeezed to overcome the elastic force of the spring 3, and shrinks to the lower end ...

Embodiment 2

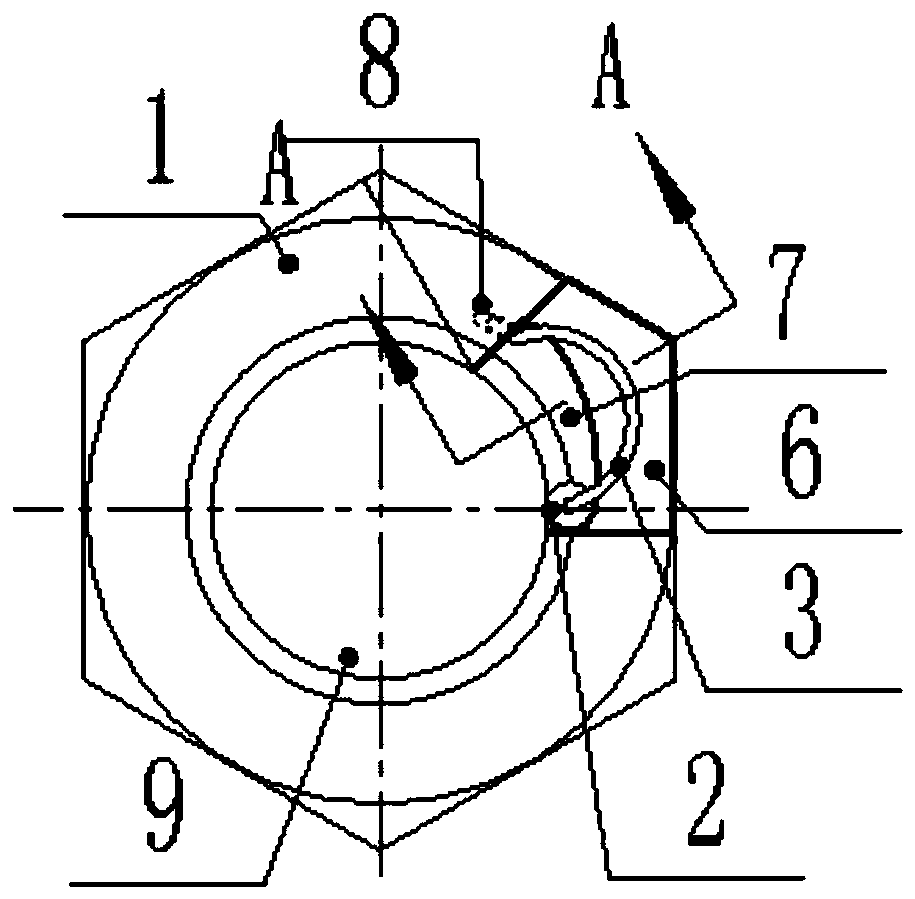

[0026] This embodiment is a rotation interlocking non-return nut, such as image 3 and 4 As shown: there is a spring groove 6 on the upper surface of the nut 1, and the special-shaped groove 7 is a groove opened on the inner edge of the nut below the spring groove. The friction angle of the nut is the rotation direction of the nut relative to the small end; a spring socket 8 is set at one end of the spring groove 6, and a spring 3 is placed in the spring groove, and the spring 3 adopts an arc-shaped special-shaped spring; One end of the spring 3 is inserted into the central hole of the rolling body, and the other end is inserted into the spring socket 8, the rolling body remains against the relatively small end of the special-shaped groove 7, and the upper end of the spring groove 6 is covered with a cover.

[0027] According to torque requirements, the number of spring grooves and special-shaped grooves on the nut is generally 1-12.

[0028] The sealing of the end surface (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com