Low-energy-consumption and environmental-friendly grain dryer

An environmentally friendly technology for grain dryers, applied in grain drying, drying machines, and drying solid materials, etc., can solve the problems of grain dryer dust, surrounding environment impact, and large power consumption, etc., to shorten the drying process and ensure Effect of grain quality and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

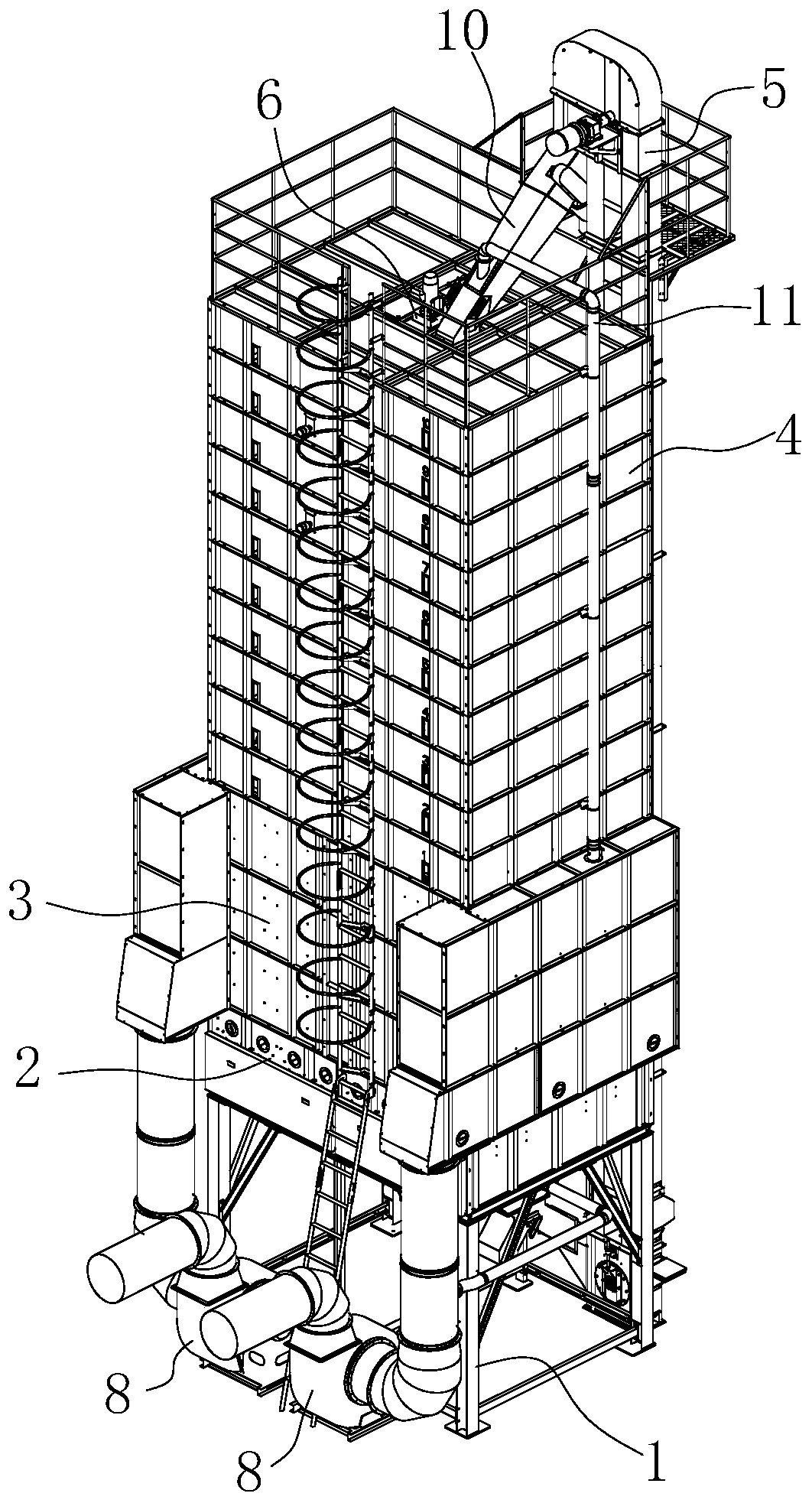

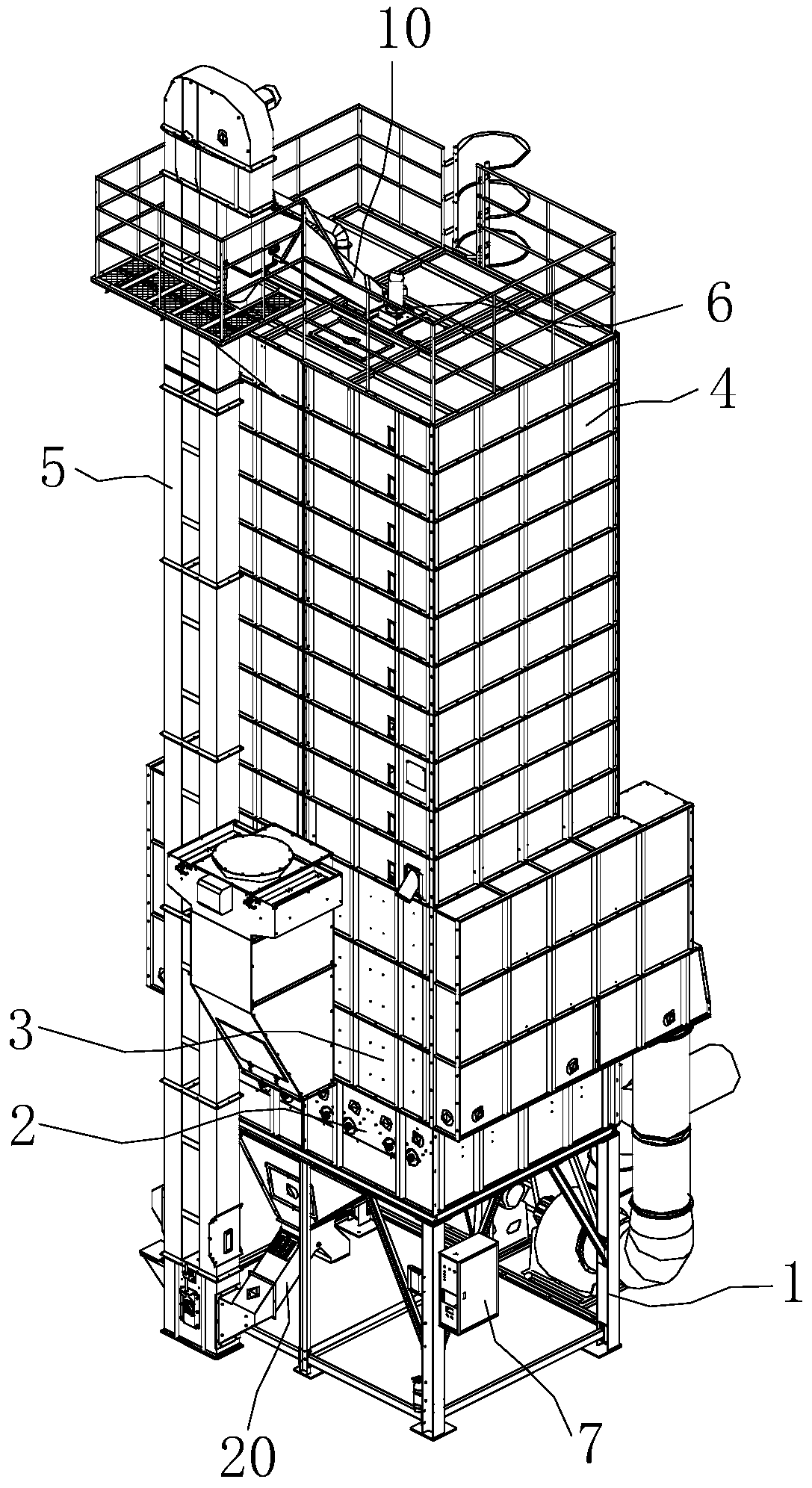

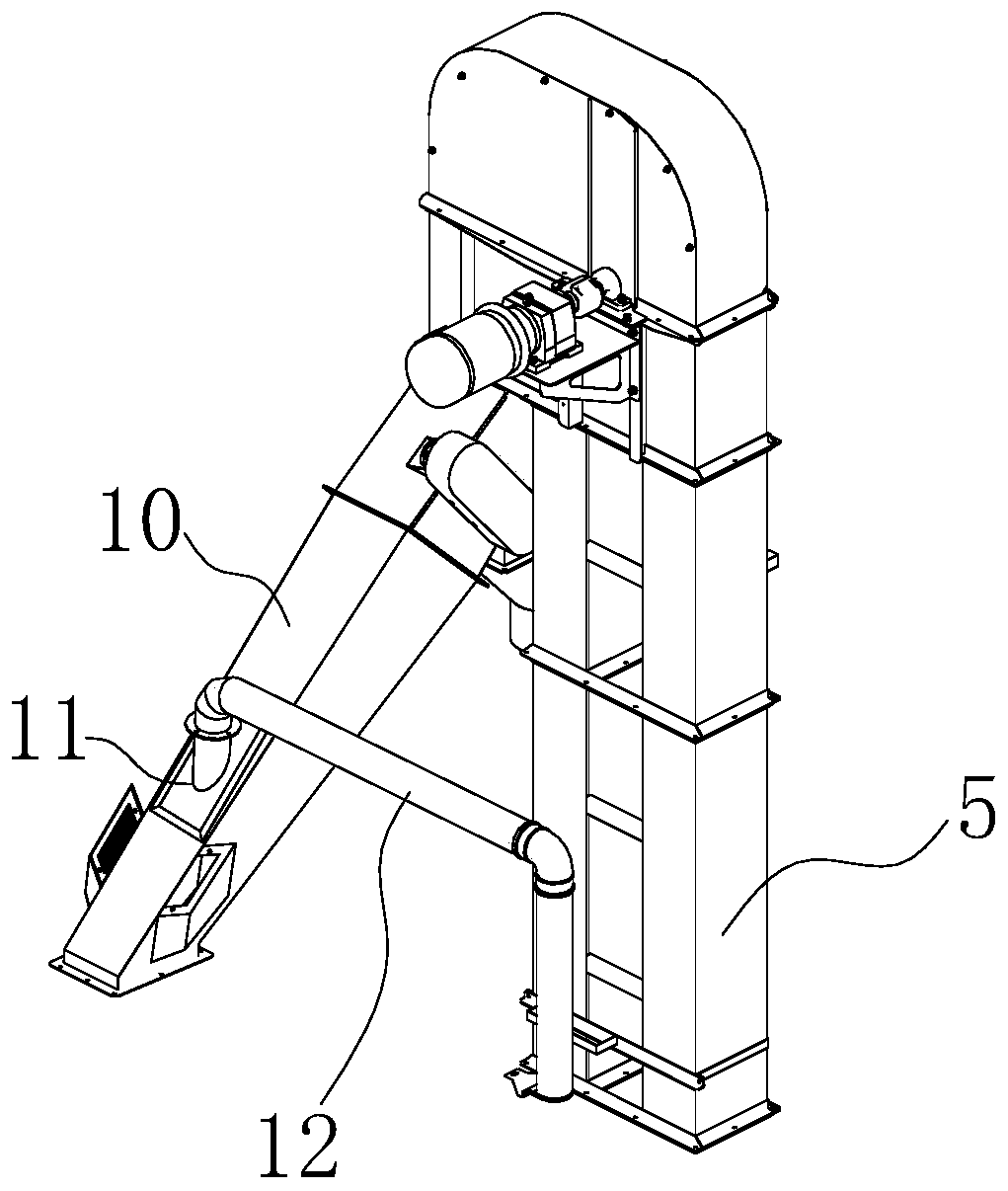

[0024] A low energy consumption and environment-friendly grain dryer, comprising a chassis 1, a grain discharge layer 2, a drying layer 3, a slowing layer 4, a hoist 5, a grain spreading mechanism 6, a control system 7, and an exhaust fan 8, characterized in that: An upper flow pipe 10 is placed obliquely between the top of the elevator 5 and the grain spreading mechanism 6, and a downflow pipe 20 is arranged obliquely between the bottom of the grain discharge layer 2 and the bottom of the elevator 5, and the upper flow pipe 10 will be lifted to the top by the elevator 5. The grain diversion is diverted in the grain spreading mechanism 6, and the downflow pipe 20 diverts the grain discharged from the grain discharge layer 2 to the bottom of the hoist 5 for circulation. The core of the present invention is to replace the traditional upper and lower auger conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com