Calibration and clamping device and calibration method for temperature and humidity sensor of Internet of Things of electric equipment

A temperature and humidity sensor and power equipment technology, applied in the direction of instruments, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problems of slow sensor response, large heating space, and large equipment damage, so as to improve test accuracy, The effect of rapid temperature and humidity rise and small confined space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

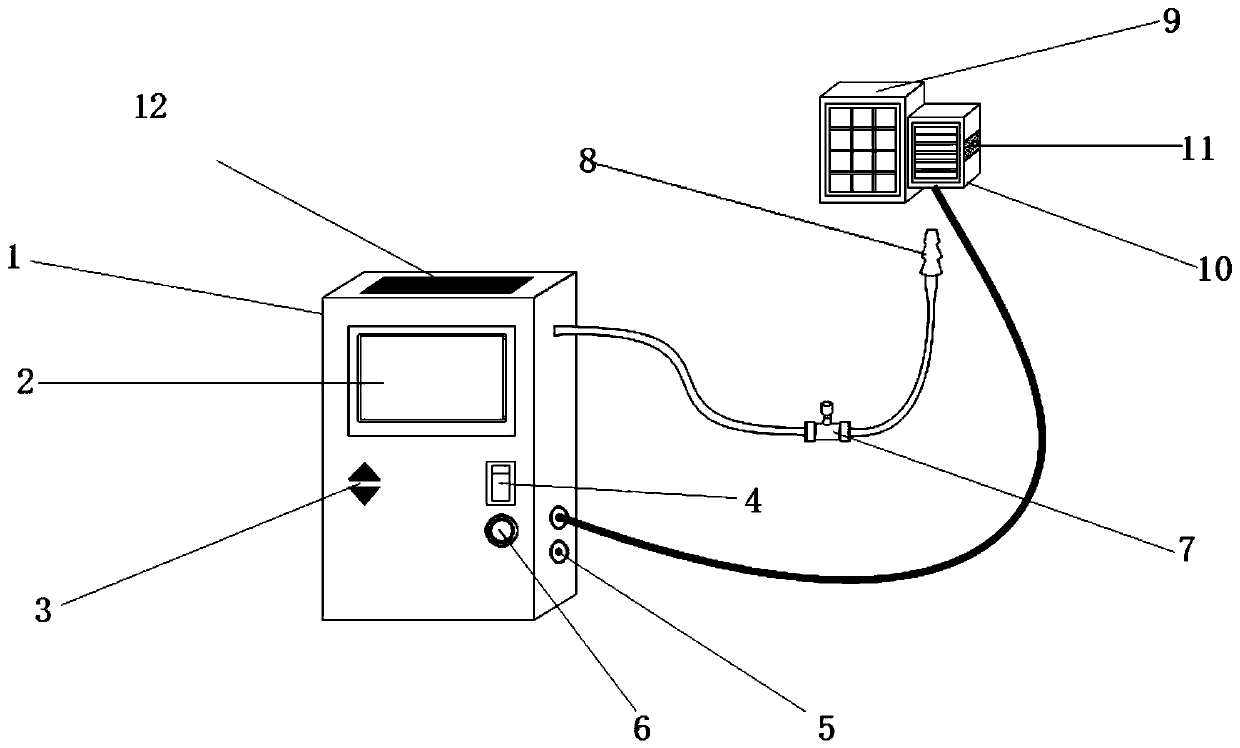

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

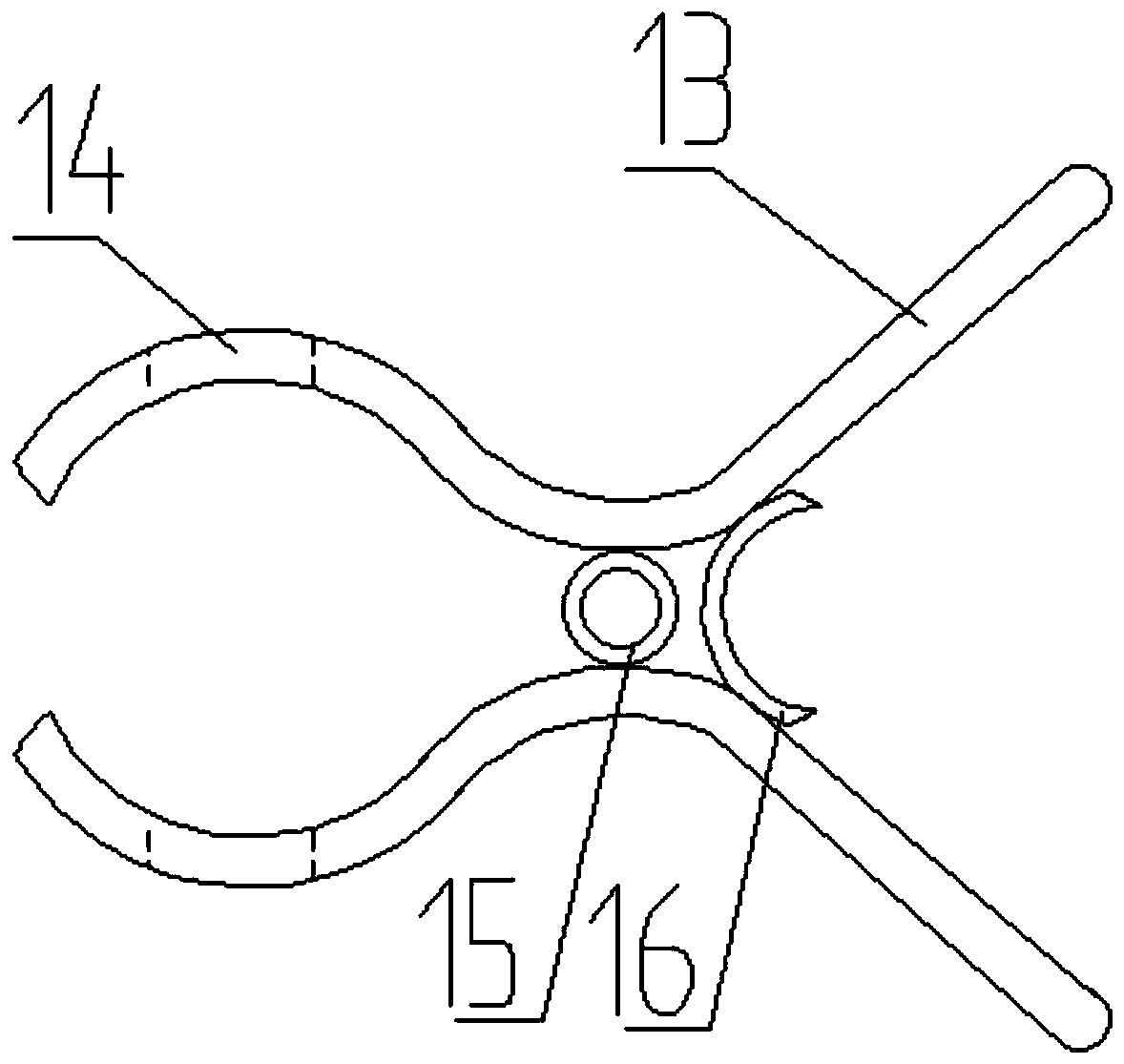

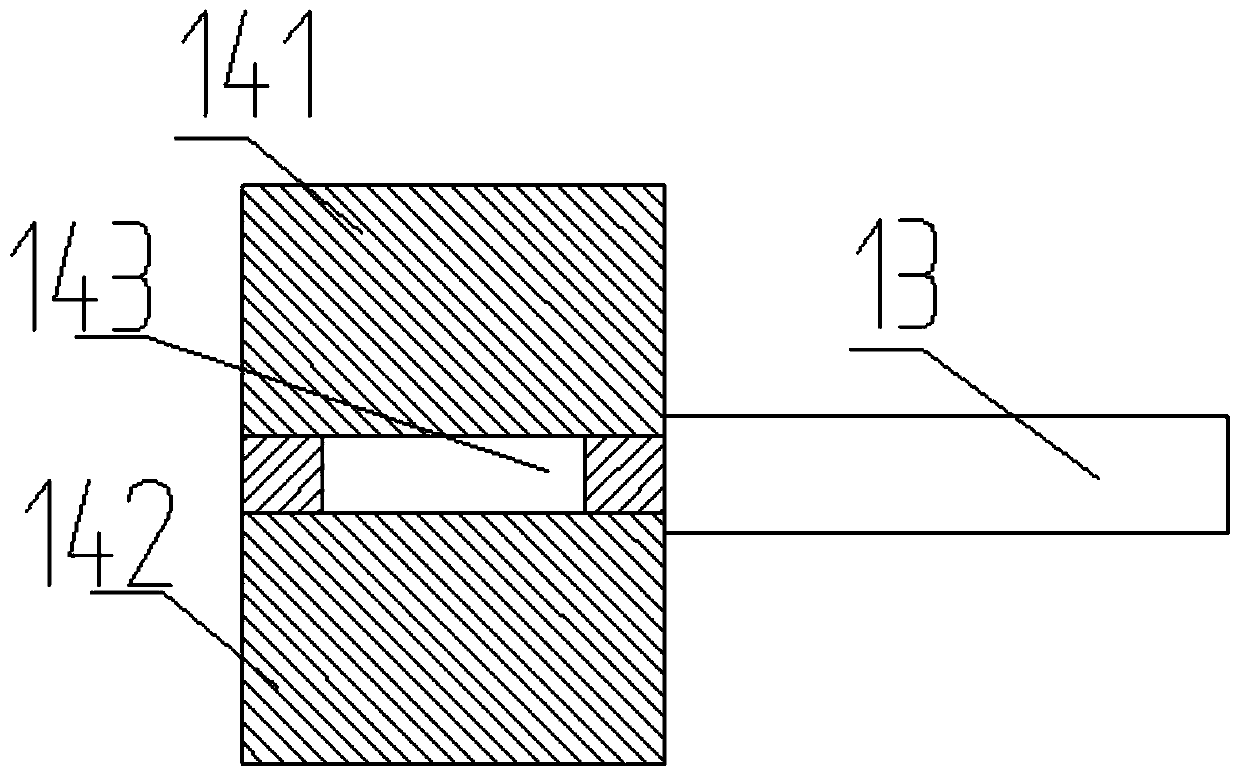

[0029] Such as figure 1 and figure 2 As shown, a clamping device for verifying temperature and humidity sensors of the Internet of Things for power equipment of the present invention includes a handle 13, a clip 14, a connecting shaft 15, and a shrapnel 16, wherein two handles 13 are connected by a connecting shaft 15, and the clip 14 is connected to the handle 13 is integrally arranged, and the shrapnel 16 is clamped between the two handles 13, so that when the handle 13 is pressed down firmly, the two clips 14 are opened, and the tested sensor 9 and the high-precision temperature and humidity sensor 10 (the present invention) can be respectively Compared with the tested sensor 9, the high-precision temperature and humidity sensor 10 is generally an order of magnitude higher than the tested sensor 9. If the temperature accuracy of the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com