Method for constructing industrial equipment fault relationship based on Granger causality verification

A causal relationship, Granger technology, applied in the field of industrial equipment fault relationship construction based on Granger causality verification, can solve the problems of lack of directivity and low accuracy, and achieve clear directivity, improve accuracy, and match high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

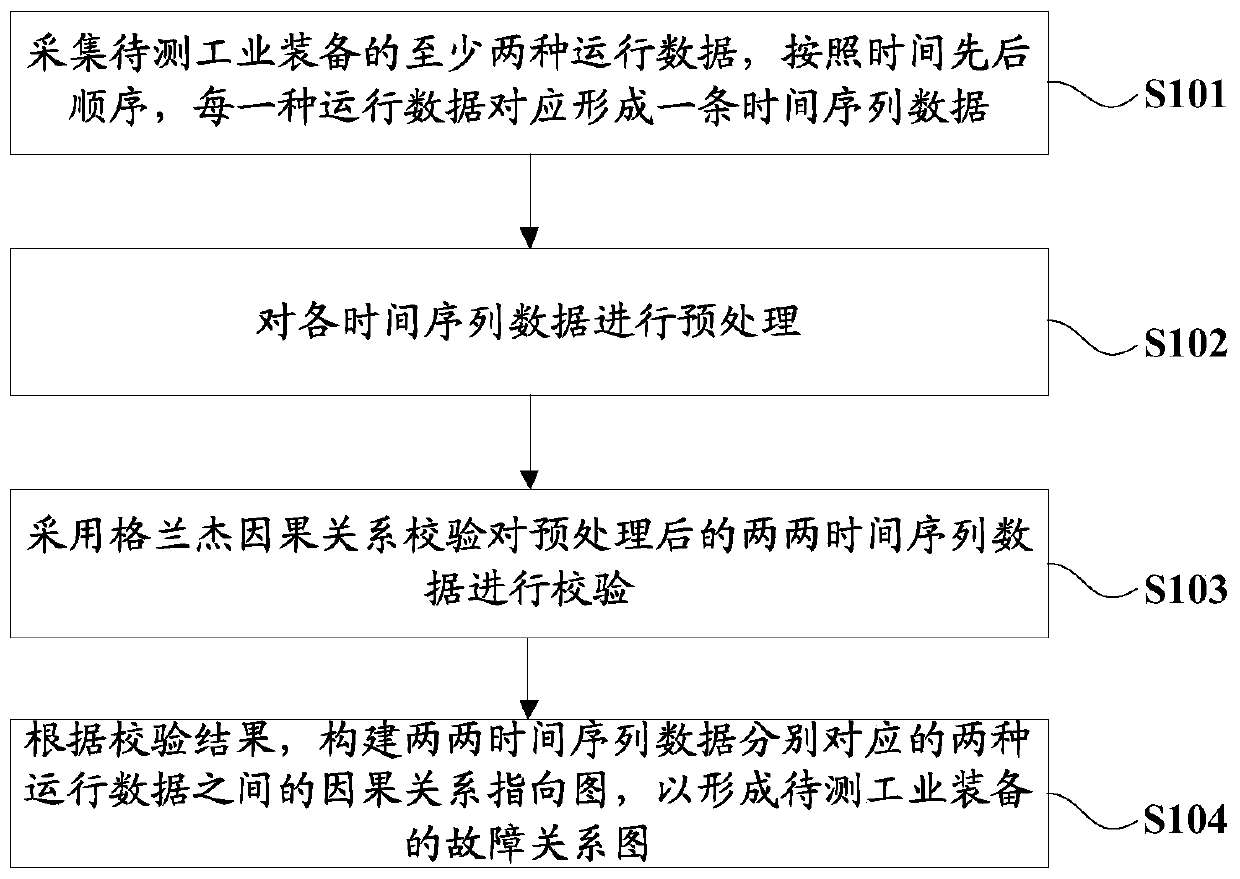

[0036] In order to solve the problem of lack of directivity and low accuracy in building fault relationships based on the correlation between operating data of industrial equipment, this embodiment provides an industrial For methods of equipping failure relations, see figure 1 , the method mainly includes the following steps:

[0037] S101. Collect at least two types of operation data of the industrial equipment to be tested, and each type of operation data corresponds to form a piece of time series data in chronological order.

[0038] In this embodiment, the industrial equipment to be tested includes, but is not limited to, an engine. Optionally, the engine includes an internal combustion engine, such as a gasoline engine, a diesel engine, and the like.

[0039] The collection of operation data can be collected by corresponding sensors, including but not limited to speed sensors, temperature sensors, power sensors, pressure sensors, voltage / current sensors and so on. Diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com