Transmission mechanism, sowing device and sowing method

A technology of transmission mechanism and driving mechanism, which is applied in the field of seeding device and transmission mechanism, which can solve the problems of sporadic planting, unstable adjustment of sowing or fertilization spacing, etc., and achieve the effect of saving material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

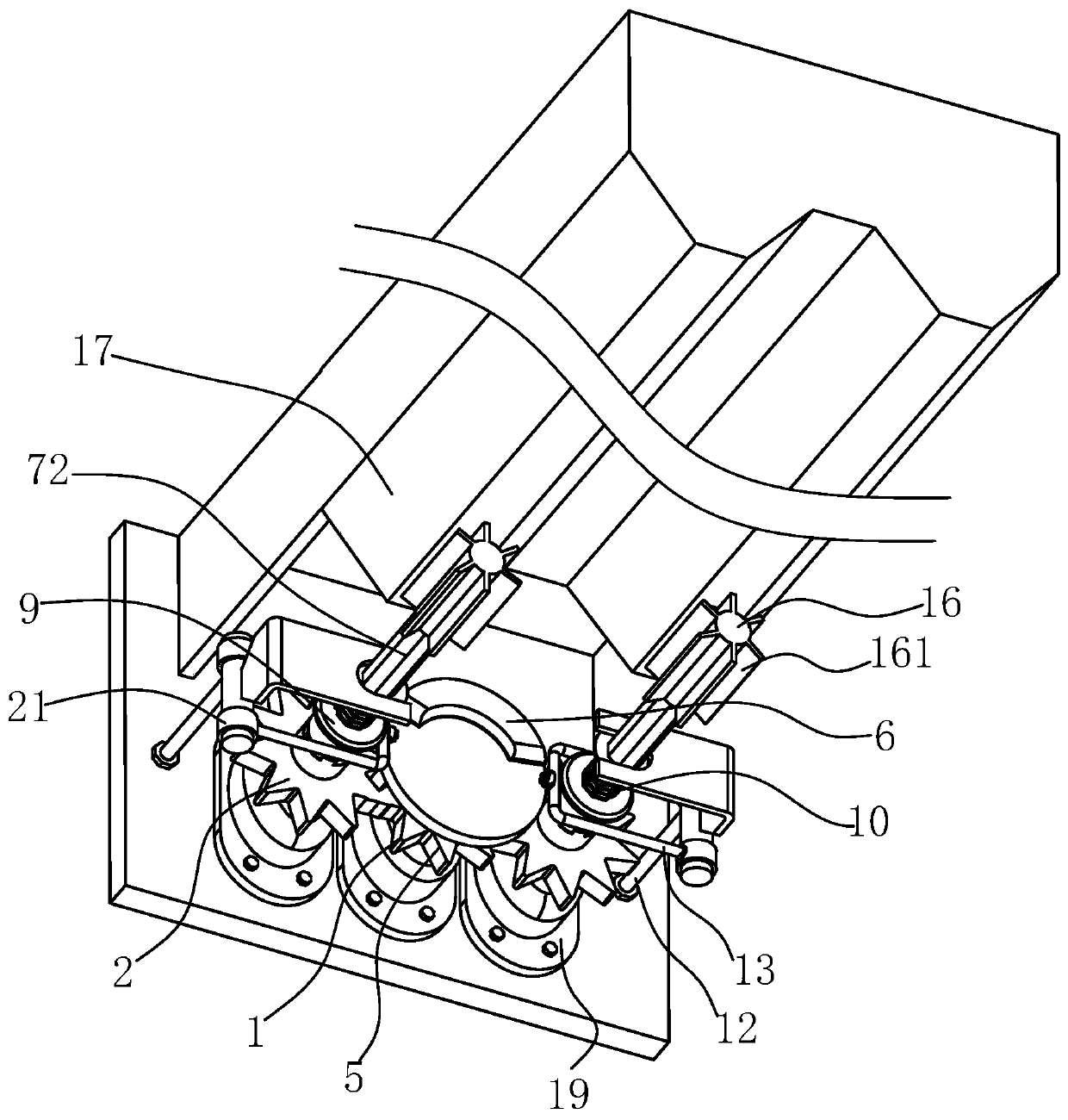

[0062] Such as Figure 1 to Figure 3 As shown, a transmission mechanism includes a base plate 11 and an intermittent driving mechanism, and the intermittent driving mechanism includes a driving part 1 and a driven part 2 driven by the driving part 1 . Specifically, the driving part 1 includes a driving shaft 3 , and the driven part 2 includes a driven shaft 4 . Two bearing seats 19 are installed on the base plate 11 , the driving shaft 3 and the driven shaft 4 respectively pass through the corresponding bearing seats 19 , and are both rollingly supported by the bearing seats 19 .

[0063] A driving wheel 5 is mounted on one end of the driving shaft 3, and a cam 6 is arranged on the driving wheel 5, and the end surface of the cam 6 is a cam, which can intermittently and smoothly push the driven part 2 to move. One side of the driving wheel 5 is fitted with a driven wheel 7 mounted on the driven shaft 4 , and in this embodiment, the driving wheel 5 is engaged with the driven wh...

Embodiment 2

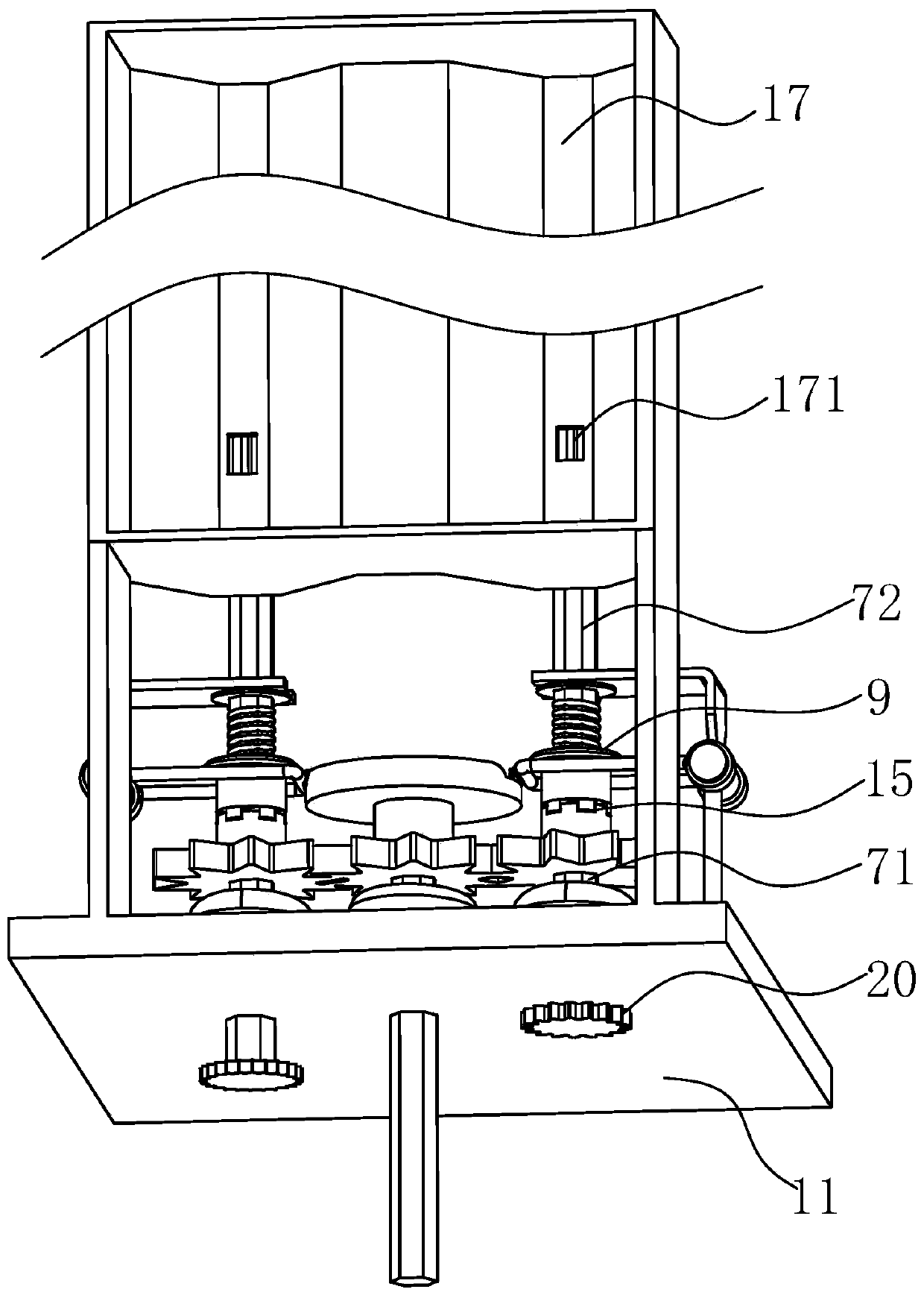

[0082] On the basis that the basic technical solution of Embodiment 1 remains unchanged, there are two sets of driven parts 2 , which are respectively located on opposite sides of the active part 1 . When the driving wheel 1 rotates, the driving wheel 1 can alternately drive the driven parts 2 on both sides to act respectively, and finally realize the control of the feeding process of the two material boxes by the driven part.

[0083] The support member 12 is an L-shaped structure, which includes the support member in Embodiment 1 (as a part of the support member 12 in this embodiment) and the limiting plate (as the two parts of the support member 12 in this embodiment, and a The first part and the second part are perpendicular to each other), and the present implementation has hinged the push rod 13 on the support member 12. Specifically, for the control of the movable half shaft 72, the present embodiment further adopts the following technical solutions:

[0084] A support...

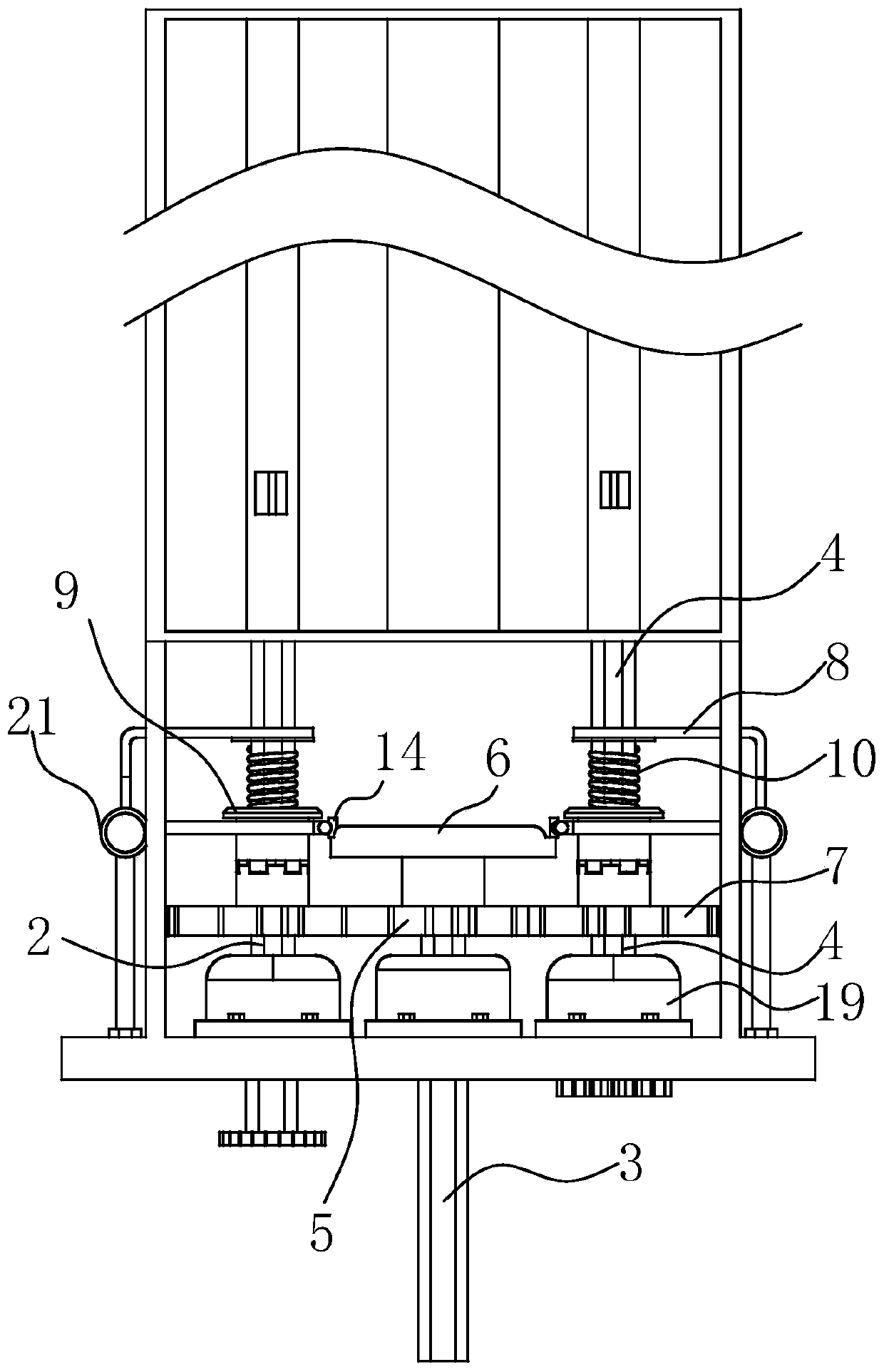

Embodiment 3

[0098] On the basis that the basic technical solution of Embodiment 1 remains unchanged, in this embodiment, a sprocket 20 is installed on the fixed half shaft 71, and another set of driven parts is arranged on the base plate 11, and the sprocket 20 is used as the driving drive. parts to drive another set of driven parts to move, and another set of newly added driven parts is used to cooperate with the installation of material boxes, so as to realize the joint fertilization or planting of multiple sets of material boxes. Specifically, in this embodiment, chemical fertilizers are placed in one set of material boxes, and bacterial fertilizers are placed in the other set of material boxes, so as to further spread the fertilizer evenly.

[0099] Of course, more driven parts and material boxes can also be set based on the above principles, including synchronous sowing of seeds with material boxes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com