Cylinder mounting machine

A cylinder assembling machine and fuselage technology, which is applied in the field of tooling for oil cylinder disassembly and assembly, can solve problems such as poor installation stability and lack of installation devices, and achieve the effects of stable oil cylinder testing, stable assembly environment, and reduced operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

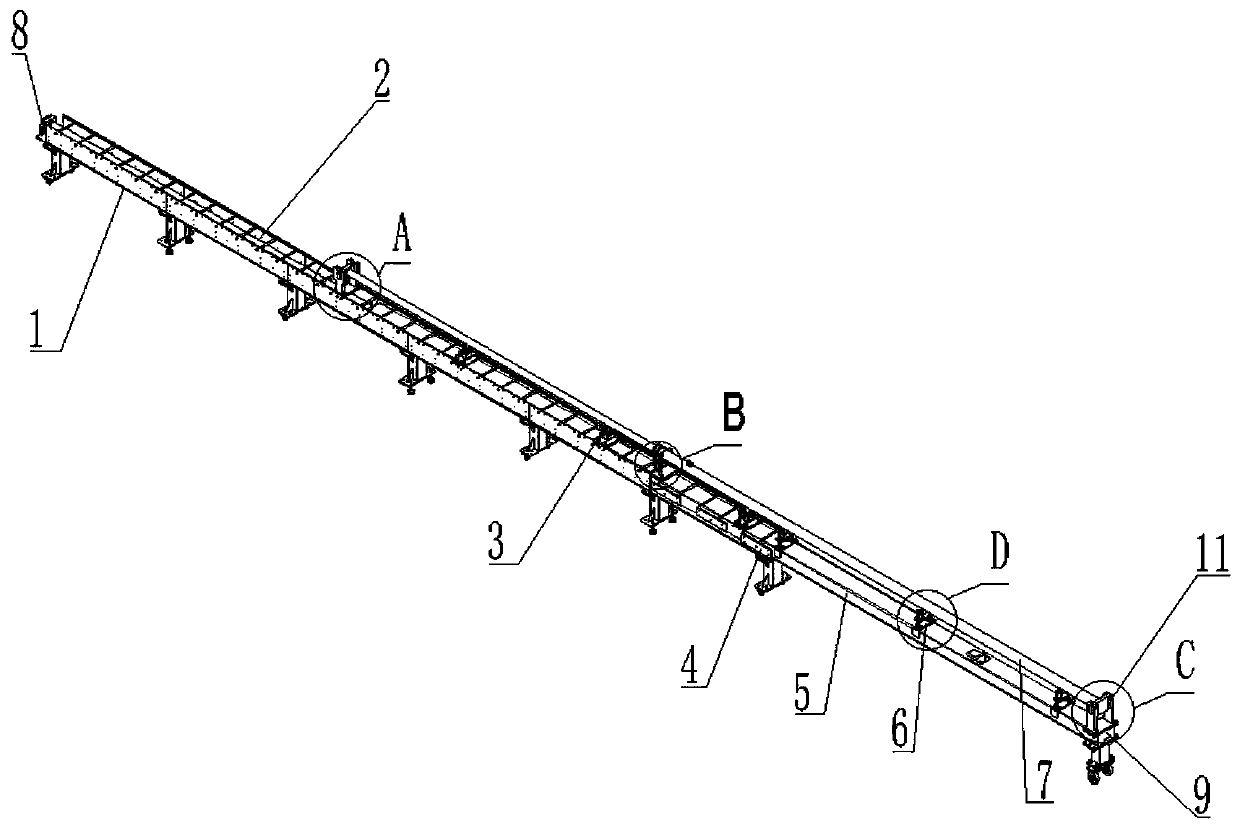

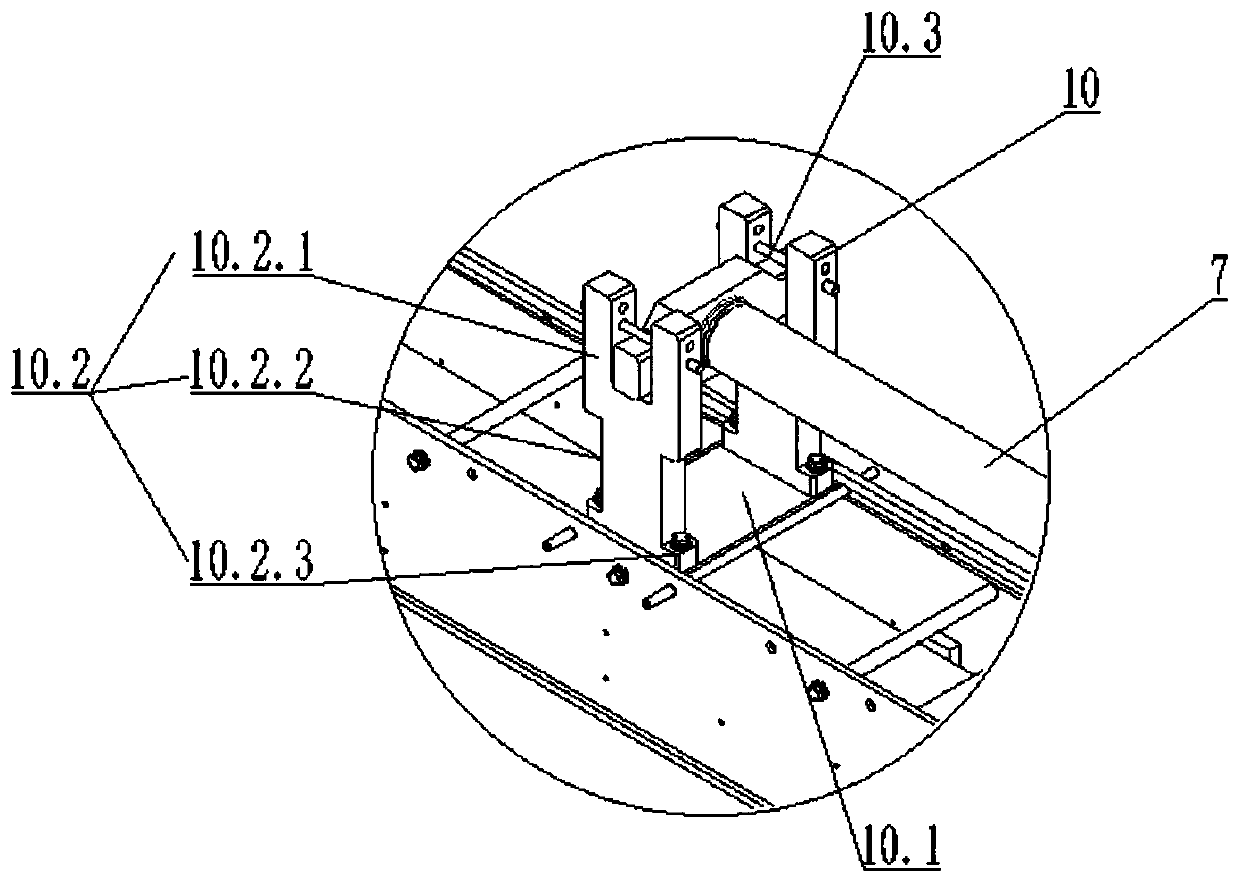

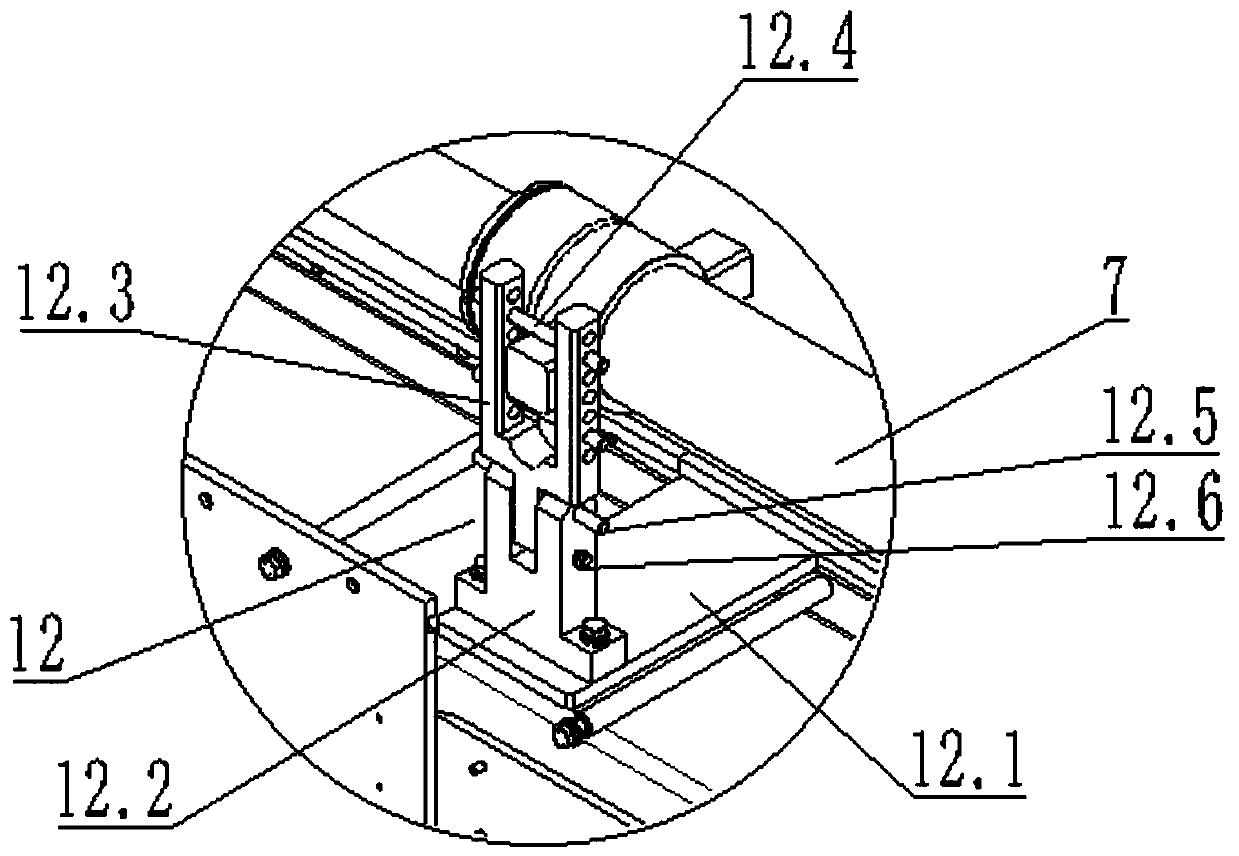

[0024] A cylinder loading machine (see figure 1), including a trough-shaped fuselage 1, a trough-shaped extension body 5 is installed in the fuselage 1, the extension body 5 can slide and expand in the fuselage 1, the extension body 5 is buckled in the fuselage 1, and stretches out The opening of the body 5 is opposite to the opening of the fuselage 1, and one end of the fuselage 1 is provided with a power cylinder fixing seat 8, and the end of the extension body 5 and the opposite end of the fuselage 1 is provided with a power cylinder fixing seat 8, and a cylinder body fixing seat 9 is provided. The end of the telescopic shaft of the power cylinder 2 is fixedly connected to the telescopic shaft fixing seat in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com